Greetings to everyone! In my previous post, we have discussed about the removal of acid gases in natural gas system. Today, we shall be discussing about the removal of nitrogen and this nitrogen can be removed by various ways. But in this particular post, we shall be looking into the absorption and cryogenic distillation processes for the removal of nitrogen from natural gas.

WHAT WE SHALL LEARN?

We shall be learning about the removal of nitrogen by two principal methods as said earlier. We shall be discussing the absorptive method and the cryogenic method for removal of nitrogen.

WHY WE NEED TO REMOVE NITROGEN?

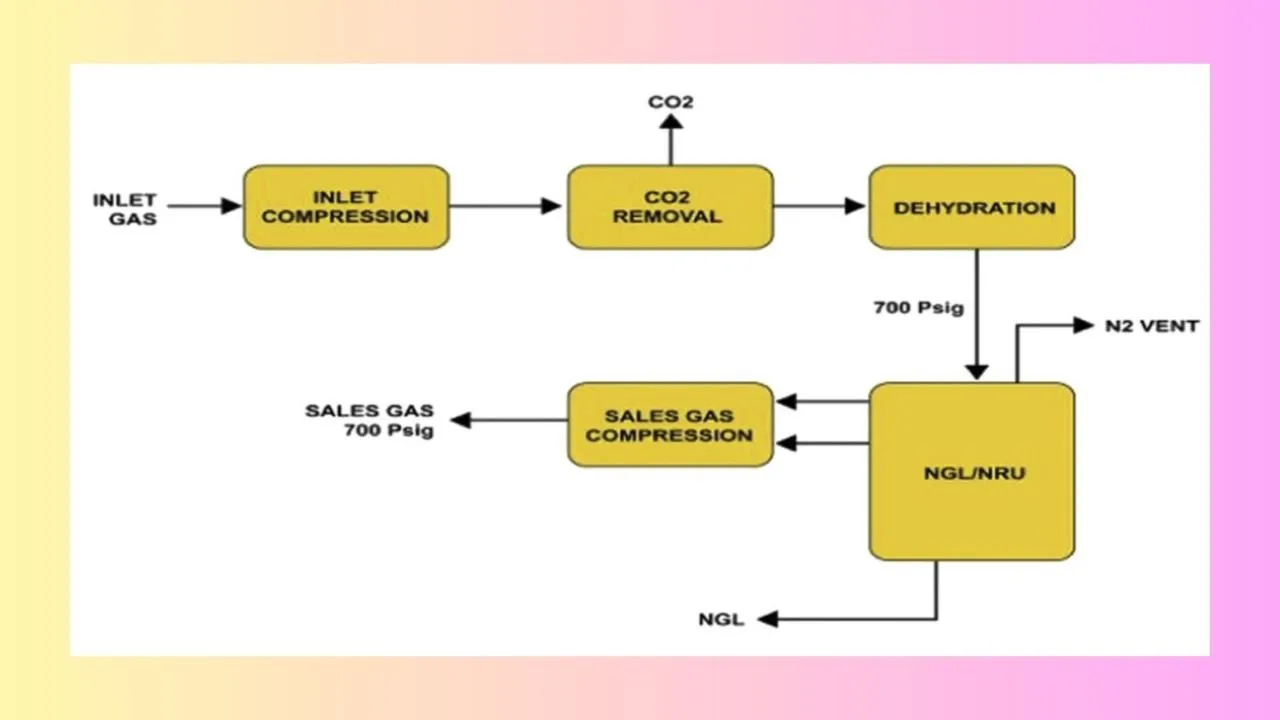

Before removing nitrogen, first we need to know the reasons behind removal of nitrogen. See, nitrogen increases the heating value of natural gas to make pipeline quality gas. If we want to exploit some sub-quality natural gas reserves then also we need to remove nitrogen from natural gas system. By sub-quality we mean that these reserves has greater than 2 mol % carbon dioxide, 4 mol % nitrogen and 4 ppm hydrogen sulphide. Again, we always have to avoid stratification and roll-over while storage and transportation of liquid nitrogen gas (LNG). This comes due to a difference in the densities which is caused by the heat leakage from the ambient. In this case, the liquid which is near to the wall gets heated up and starts moving up and the liquid which is colder on the inner side will start coming down. This kind of temperature gradient causes a difference in the densities which in turn causes some kind of stratification. The nitrogen can also be used for enhanced oil recovery. It can be used to recover any kind of oil residual which remain in the crevices of the sediment. We can also separate helium from nitrogen in a helium recovery unit as natural gas is the commercial source of production of helium and helium is obtained from this nitrogen recovery unit (NRU)

NITROGEN RECOVERY UNIT

In the nitrogen recovery unit (NRU), we have various processes such as absorption, cryogenic distillation, adsorption, membrane separation and hydrate formation. We shall limit our discussions to the first two processes only.

ABSORPTIVE NITROGEN REMOVAL: Methane Absorption

It is not a very handy practice as the cost becomes quite high when we consider large scale production of LNG. By large scale I mean more than 30 MMSCFD (Million standard cubic feet per day). The high cost is due to the increase in solvent rate and methane compression. Of late some nitrogen selective solvents are being used to reduce the cost.

In this process, the methane gas is absorbed by some lean oil at about -32°C and then it is recovered by multiple flash of the rich oil. The recovered low pressure methane has to be recompressed for pipeline or cryogenic gas plant feed. This is why, researchers are working on to selectively remove nitrogen rather than methane so that we could avoid this subsequent flash operations of the methane rich oil. The nitrogen from the feed gas goes to the top of the absorption column to pre-cool the feed before getting vented out.

There have been some organometallic complexes (OMCs) developed to absorb nitrogen and potential development may compete with the cryogenic NRU. But there are some barriers in the development of such OMCs. These OMCs cost so high and these can be contaminated by water and hydrogen sulphide. OMC is pyrophoric i.e., they can catch fire spontaneously if brought in contact with air.

CRYOGENIC DISTILLATION NRU

Next, we have the cryogenic distillation to remove nitrogen and this is the most common method. It is based on the difference in the volatilities of the two gases i.e., methane and nitrogen.

| Species | CH4 | N2 |

|---|---|---|

| Normal boiling point | 111.5 K | 77 K |

| Boiling point at 3150 kPa | 178.3 K | 124.3K |

The distillation can produce high purity methane at high recovery rates and less than 3% methane in the overhead nitrogen. There can be use of one or more than one column in cryogenic NRU. When the nitrogen content is more than 20 mol% then two columns are used.

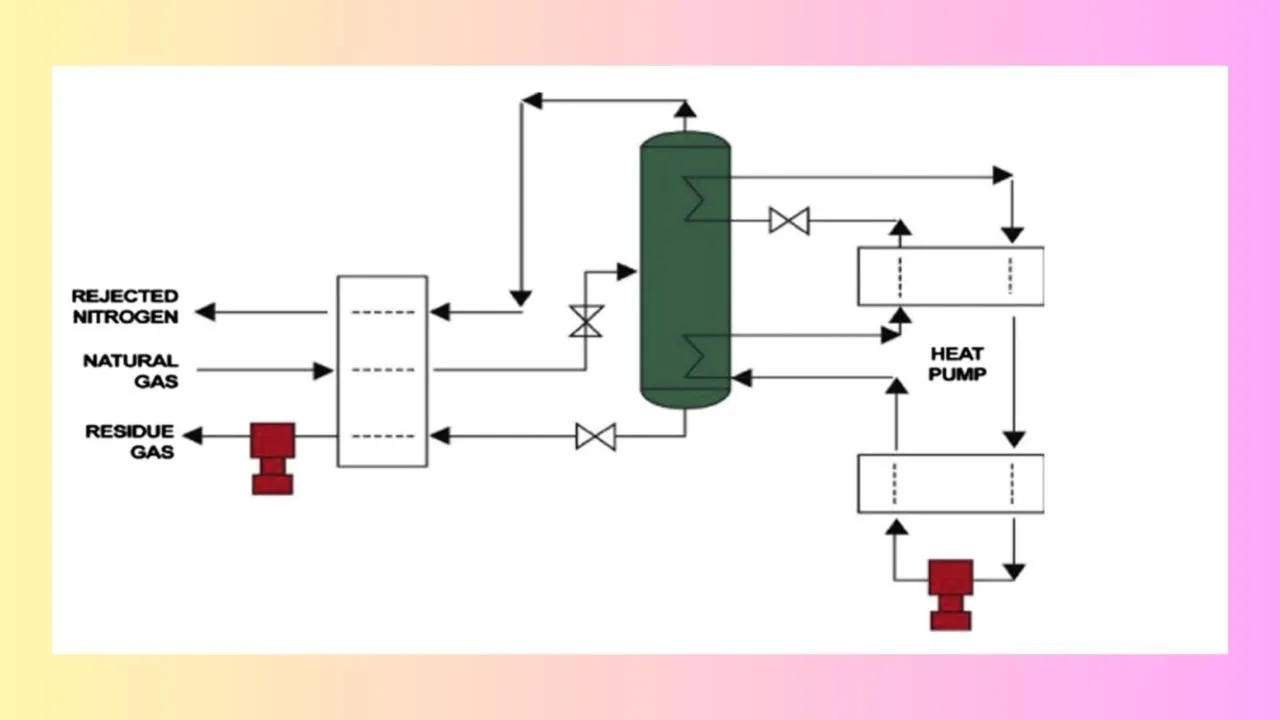

Single column cryogenic distillation NRU

In a basic single column cryogenic distillation NRU, the natural gas at about 3000 kPa goes into the column. In the column first removal of water, CO2 and higher hydrocarbon is done because they can get frozen inside the pipelines. The N2 gas is then cooled, throttled and fed to an intermediate stage of the distillation column at pressures of 1300-2800 kPa. The rejected N2 rich vapor drawn from the top has less than 1 mol % CH4 and the methane rich liquid (about 98 mol% CH4) is drawn from the bottom and it helps to cool down the incoming nitrogen before it is taken for compression and up gradation of the natural gas. The bottom product can be reheated with the feed gas.

A heat pump is used by using methane as the working gas and this pump is used to cool down the nitrogen at the top and reboiler is used to heat it up for distillation. Methane is condensed at high pressure in the reboiler and vaporized at low pressure in the condenser. With the increase in the N2 content, the CH4 condensation in the upper stages becomes more difficult.

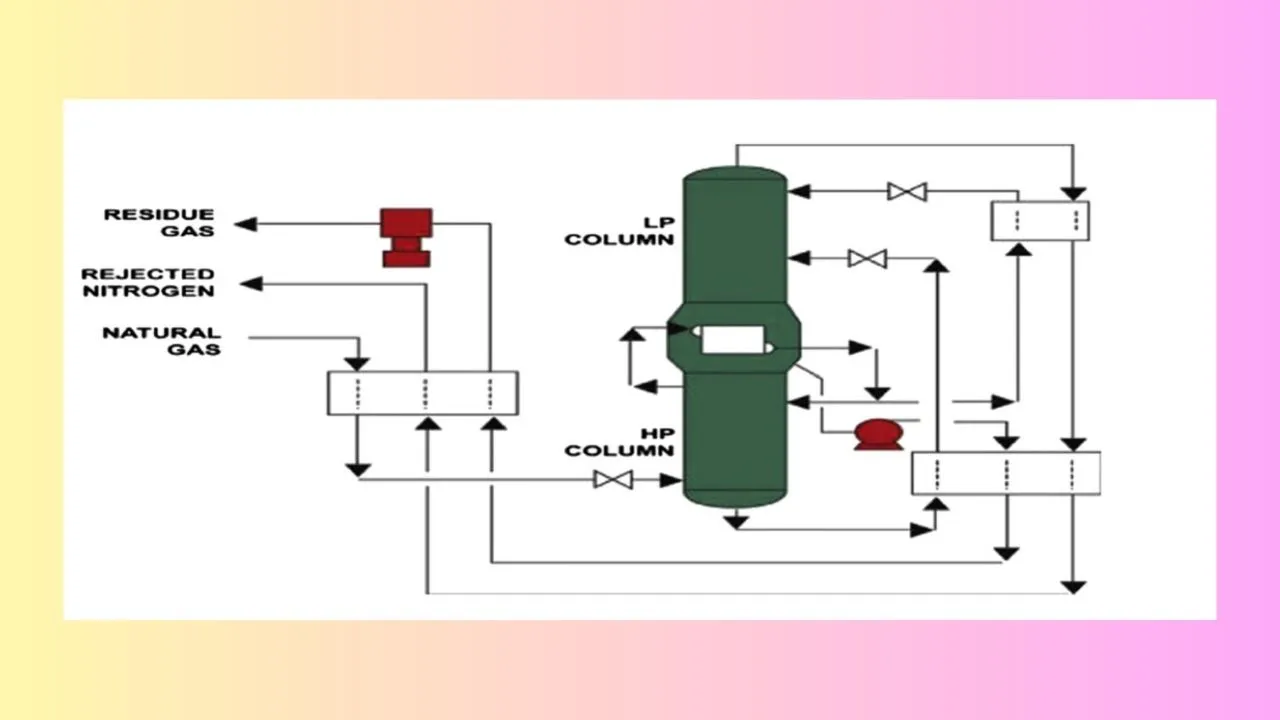

Double column cryogenic distillation NRU

For higher amount of nitrogen, we use the double column cryogenic distillation. Firstly, the raw nitrogen gas is decontaminated from water, carbon dioxide and higher hydrocarbons are fed to the high pressure lower column at 1000-2500 kPa. The lower column operates at higher pressure whereas the top column operates at a lower pressure. The feed is taken to the lower column and some nitrogen is removed due to flash. The liquid from the bottom of this column is taken as the feed after throttling and it is then taken as the feed for the top column which operates at about 150 kPa. From this particular column, both methane and nitrogen rich streams are taken out before they are pass through a three channel heat exchanger.

There is some sort of heat integration to internally cool down the hot stream and we get methane from the bottom of the top column. A particular column is responsible for the separation of the methane and the nitrogen. The nitrogen rich vapor from the high pressure column is condensed to provide the reboiler duty for reboiling the liquid in the top column and the low pressure column produces high purity nitrogen which is used to cool the nitrogen reflux fed to the low pressure condenser. For LNG production, methane rich bottom products from low pressure column may remain liquid. So, from here we are getting the methane product which can remain in the liquid phase.

Pros and cons of different Nitrogen Removal Unit (NRU) technology

Department of Cryogenic Engineering Centre

Acid Gas Removal in Natural Gas System-II |ChemFam #19|

Acid Gas Removal in Natural Gas System-I |ChemFam #18|

Estimation of Water Content in Natural Gas |ChemFam #17|

Membrane Separation in Natural Gas System |ChemFam #16|

Design of distillation column |ChemFam #15|

Separation Technique: Distillation |ChemFam #14|

Transmission Electron Microscope: Principle and Working |ChemFam #13|

Scanning Electron Microscope: Principle and Working |ChemFam #12|

Drugs: Classification and drug-target interaction |ChemFam #11|

What are orbitals and quantum numbers? |ChemFam #10|

Quantum mechanical model of an atom |ChemFam #09|

A case study about the growth mechanism of CNT |ChemFam #08|

Carbon Nanotubes (Buckytubes): Types and Synthesis |ChemFam #07|

Nanomaterials: Classification and Approach for Synthesis |ChemFam #06|

Azadirachtin: Isolation, Extraction and Mechanism of Action |ChemFam #05|

Woodward-Fieser Rules for Calculating λmax |ChemFam #04|

Chemistry in ancient India |ChemFam #03|

How do soaps clean the dirt? |ChemFam #02|

What is anti egg white injury factor? |ChemFam #01|

PS The thumbnail image is being created by me using canva.com taking template image from ResearchGate