So I had an inspector come and check out my trailer early on. He was concerned with the suspension, the equalizer and shackles in particular, which were very low quality. As a matter of fact, the equalizer had 'Made In China' stamped on it. I decided to do a little research and found endless Youtube videos and forum posts about failures of the stock suspension components on 5th wheels. Because I intend to travel cross country with this trailer, I thought the prudent thing would be to upgrade the entire suspension in advance.

Here is a brief description of the suspension components according to Venice.ai with my comments under each one:

Leaf Springs: Long, curved pieces of metal that attach to the trailer frame and the axle, providing the primary suspension support and helping to distribute the trailer's weight.

You can see from the photo below the stock leaf springs are fairly thin. These are a common item to fail on trailers

Equalizer: A pivoting component that connects the leaf springs to the trailer frame, allowing the springs to move up and down and helping to maintain the trailer's stability.

The stock equalizer on my trailer was stamped 'Made In China' and looked fairly weak and flimsy. Its simple design also did a poor job of distributing the weight between the two axles.

Shackles: Metal straps or links that connect the leaf springs to the equalizer, allowing for flexibility and movement in the suspension system.

The stock shackles were also very thin and not uncommon for them to fail.

Bushings: Rubber or plastic inserts that fit into the shackles and equalizer, providing a smooth, quiet ride by reducing friction and vibration.

The default bushings were already heavily damaged when I removed them, after only less than 1000 miles of use. Without them there was no lubrication between the bolts and the eyes of the leaf springs.

Axle: A rod or beam that supports the trailer's wheels and is attached to the leaf springs, transmitting the trailer's weight and stress to the suspension system.

The stock axles looked fine and are rated for 7,000 pounds each which should be plenty. If they ever failed I'd consider installing 8k axles.

Hangers: Brackets that attach to the trailer frame and support the leaf springs, helping to maintain the suspension's alignment and stability.

The stock hangers were already very good. Many people have reinforcements welded into place, but on my particular trailer they were already installed, so I was happy about that.

U-bolts: Bolts that attach to the axle and leaf springs, securing the axle in place and providing additional support to the suspension system.

U-bolts stretch over time, so it's recommended to replace them whenever you remove them.

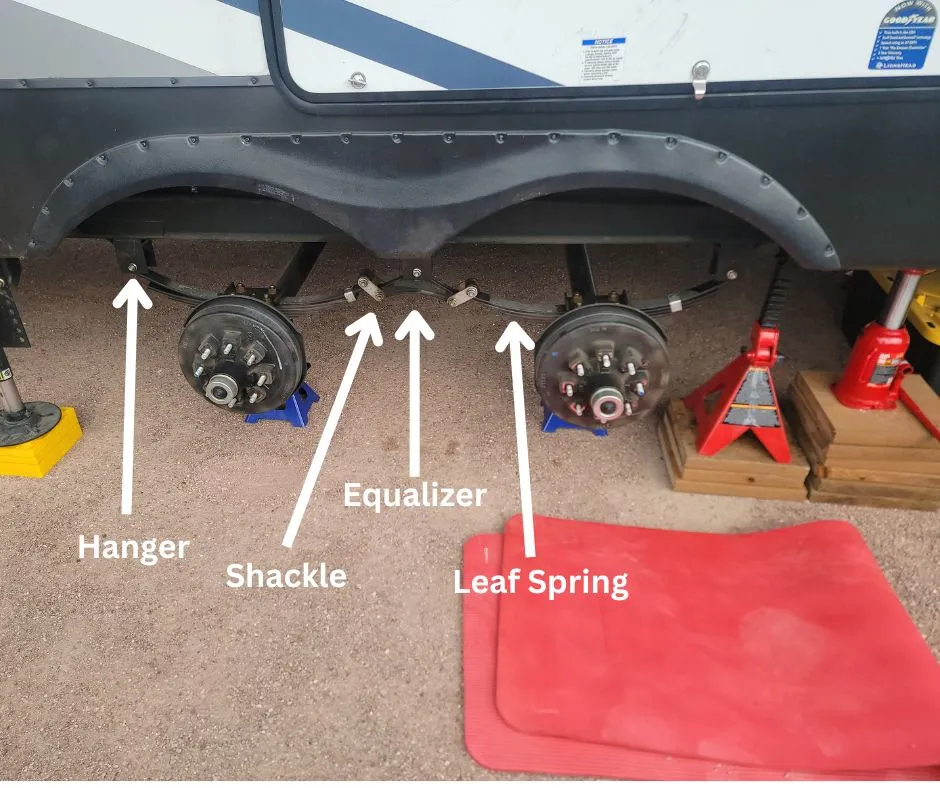

In this photo, In preparation of performing the upgrades, I have one side of my trailer up on jacks. I then removed the wheels, and supported each axel with a small jack stand.

Here I have removed the entire assembly as one piece. The eyes at the end of the leaf springs, and the plastic bushings inside of them are now visible. The axles are now entirely supported on one side by jack stands.

My first step is to install the new equalizer on the center hanger. The new equalizer is a Lippert Road Armor, which is a huge upgrade from stock. The Road Armor has two arms and hard rubber shock pads. They absorb shock and vibration and better shares them between the axles.

Here I have a photo of the new 8k leaf springs compared to the old 7k leaf springs. You can see there is a huge difference in 'beefiness' between the two. You can also see the old equalizer here and visually compare it to the Road Armor I just installed.

One new leaf spring is installed with new bronze bushings (instead of plastic), much thicker shackles, and wet bolts. What is a wet bolt you ask? A wet bolt has a fitting on it that allows you to lubricate it using a grease gun. This keeps a constant layer of grease between the bronze bushing and the bolt. Unlike with plastic bushings, this combination wears much slower. The downside is that you must regularly lubricate them.

In this photo I have everything installed, including the U-bolts. The U-bolts are secured to the axle with a plate and 4 nuts and washers, which you can see here.

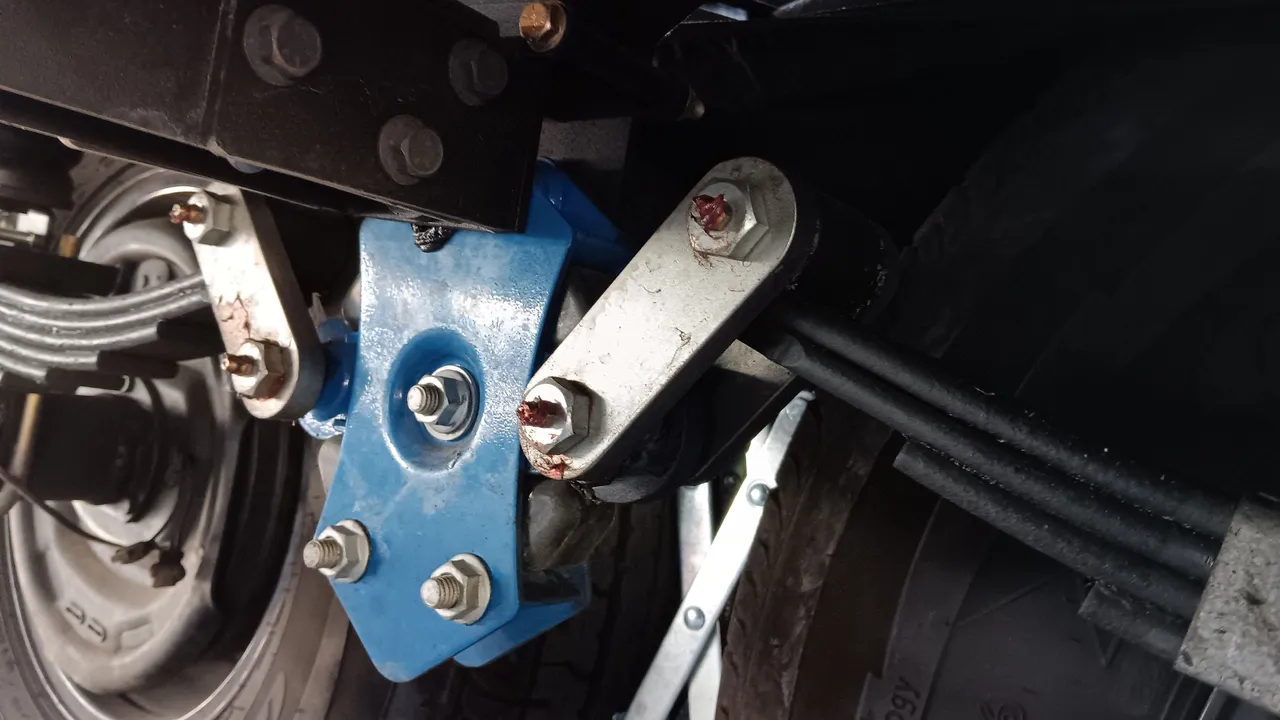

Here is a really good view of the reinforcements for the hangers. They welded a plate on either side from the lip of the frame to the frame itself, and they also welded a pair of 45 degree plates inside the hanger itself. Many trailers don't come with these features, and hangers are known to grow weak and break off over time. In this photo you can also see a bracket with two bolts attached to the hanger. These are for some crossbars I also installed.

In the picture above you can see the three crossbars I installed. They tie each hanger together, increasing the rigidity of the suspension, especially in tight turns. You can look at the previous photos and see where are not tied together. Hangers are essentially two pieces of thin metal 'hanging' straight down from the frame--they don't have much in the way of lateral strength. This is also an excellent shot of the U-bolts and plates.

In the above photo you can see a closeup of the back side of the new equalizer. You can also get a feel for how thick the new shackles are. You can also see fresh grease on the zerk fittings, which are used to grease the wet bolts.

After a few hundred miles I added Sumo Springs, also referred to as helper springs. They go between the U-bolt plate and the frame of the trailer, adding additional shock absorption. They really do help the leaf springs, smoothing the ride and making them less likely to fail.

Since I had never done this before, I've inspected my work and retorqued the bolts multiple times. It's gone about 1000 Miles in this configuration. The trailer rides much smoother. I've left items on countertops which before would have been knocked off, only to arrive at a destination 200 miles later and they haven't moved. The less shock and movement of your trailer, the less your components tend to fail. Also, your trailer sways a lot less in the wind, and when passing other semi trucks going in either direction.