Space manufacturing refers to the production of goods and materials in space, rather than on Earth. This can include the manufacture of components for spacecraft, satellites, and other space-based systems, as well as the production of materials and components for use in space exploration and development, such as space suits, spacecraft structures, and propulsion systems.

There are several potential advantages to space manufacturing, including:

- Reduced gravity: In space, there is less gravity to contend with, which can make certain manufacturing processes easier and more efficient. For example, it is easier to pour molten metal in space, as it does not sag or deform under its own weight.

- Unlimited resources: Space contains vast resources, such as solar energy, lunar regolith, and asteroid minerals, that can be harnessed and processed for use in manufacturing.

- Zero-gravity research: Space manufacturing can also enable scientific research in zero-gravity environments, which can provide valuable insights into areas such as material science, fluid dynamics, and biology.

- Cost savings: Space manufacturing can potentially reduce costs associated with manufacturing on Earth, such as energy consumption, labor costs, and environmental regulations.

- On-orbit assembly: Space manufacturing can also enable the assembly of large structures and systems in space, which can be difficult or impossible to achieve on Earth due to size and weight constraints.

There are several challenges associated with space manufacturing, including:

- Cost: Space manufacturing is still a relatively expensive endeavor, as it requires significant resources and infrastructure to establish and maintain a presence in space.

- Distance: Space manufacturing facilities are typically located far from Earth, which can make it difficult and expensive to transport materials and components back and forth.

- Radiation: Space is filled with harmful radiation, which can damage materials and components, and pose health risks for astronauts and space travelers.

- Microgravity: While microgravity can provide some advantages in manufacturing, it can also pose challenges, such as the difficulty of manipulating and handling materials in zero-gravity environments.

- Legal and regulatory frameworks: Space manufacturing is a relatively new field, and there is a need for legal and regulatory frameworks to be developed to govern activities in space.

Despite these challenges, space manufacturing is a rapidly growing field, with several companies and organizations already active in this area. Some examples of space manufacturing include:

- SpaceX: SpaceX has developed advanced manufacturing capabilities for its rockets and spacecraft, including the ability to produce lightweight, high-strength components using 3D printing techniques.

- Blue Origin: Blue Origin has developed a range of manufacturing technologies for its New Glenn rocket, including the use of robotic welding and automated assembly processes.

- NASA: NASA has a long history of space manufacturing, dating back to the Apollo era, and continues to develop new technologies and techniques for space manufacturing, such as the use of advanced composites and 3D printing.

- European Space Agency: The European Space Agency (ESA) has a strong focus on space manufacturing, with a range of initiatives aimed at developing new technologies and capabilities for space-based manufacturing.

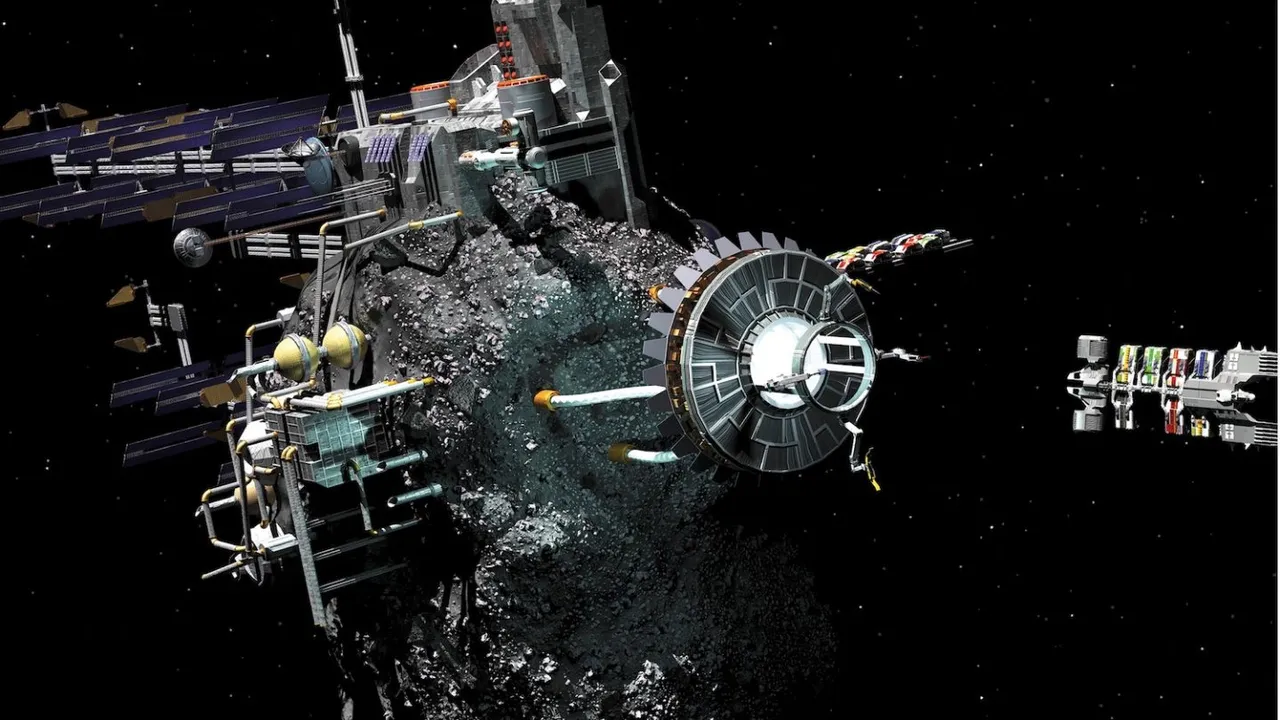

- Planetary Resources: Planetary Resources is a company that aims to mine asteroids for valuable minerals and metals, which could be used in space manufacturing processes.

Overall, space manufacturing has the potential to revolutionize the way we produce goods and materials, and could play a key role in the development of a sustainable future.

Space manufacturing, also known as in-space manufacturing, refers to the production of goods and materials beyond Earth's atmosphere. This concept involves harnessing the unique environment of space, like microgravity and vacuum, to create products that are either impossible or significantly more efficient to manufacture on Earth.

Here are some key points to understand about space manufacturing:

Benefits:

- Microgravity: The absence of gravity allows for creating materials with unique properties, like extremely pure crystals or perfectly spherical objects, which are often difficult or impossible to achieve on Earth.

- Vacuum: The near-perfect vacuum of space facilitates processes like vacuum deposition and high-precision 3D printing without contamination, leading to improved material quality and production efficiency.

- Unlimited Resources: Utilizing resources available in space, like asteroid minerals or lunar regolith, could decrease dependence on Earth's resources and potentially unlock new materials and economic opportunities.

- Reduced Costs: In the long term, producing certain goods in space, especially those required for further space exploration or space-based habitats, could be more cost-effective than transporting them from Earth.

Challenges:

- High initial investment: Establishing manufacturing infrastructure in space is expensive and requires significant technological advancements.

- Logistics and transportation: Sending raw materials and equipment to space and returning finished products back to Earth presents logistical challenges and high costs.

- Radiation and harsh environment: Spacecraft and manufacturing facilities need to be protected from radiation and extreme temperature fluctuations.

- Psychological and social considerations: Astronauts working in space manufacturing facilities might face psychological and social challenges due to isolation and confinement.

Current Status:

- While still in its early stages, space manufacturing is showing promising progress.

- Experiments on the International Space Station (ISS) are demonstrating the feasibility of manufacturing crystals, pharmaceuticals, and even simple tools in space.

- Private companies like Made In Space and Space Forge are developing 3D printing technologies and other techniques for space-based production.

Future Potential:

- Space manufacturing could become a crucial aspect of long-term space exploration and potentially lead to the development of self-sustaining space colonies.

- Applications might include:

- Production of spare parts and tools for space missions.

- Construction of large structures in space using lunar or Martian materials.

- Manufacturing of pharmaceuticals and other high-value products with unique properties in microgravity.

- Processing asteroid resources for materials or even fuel.