I can make stuff out of hot steel now! I completed 16 hours of blacksmith classes this weekend at Floyd Center for Arts and it was blast. It was even better than I expected. We didn't waste any time at all. After a brief introduction and safety instructions we were firing up our forges and hammering steel. I never expected to pick it up so easily. Not that I'm a professional now or anything but I figured we'd spend a lot of time on techniques and wouldn't really get to make anything that we wanted. However, after a few pointers we were tapering off our steel, making rat tails, and any number of shapes. The rest of the first day and all of the second day we were free to make whatever we wanted.

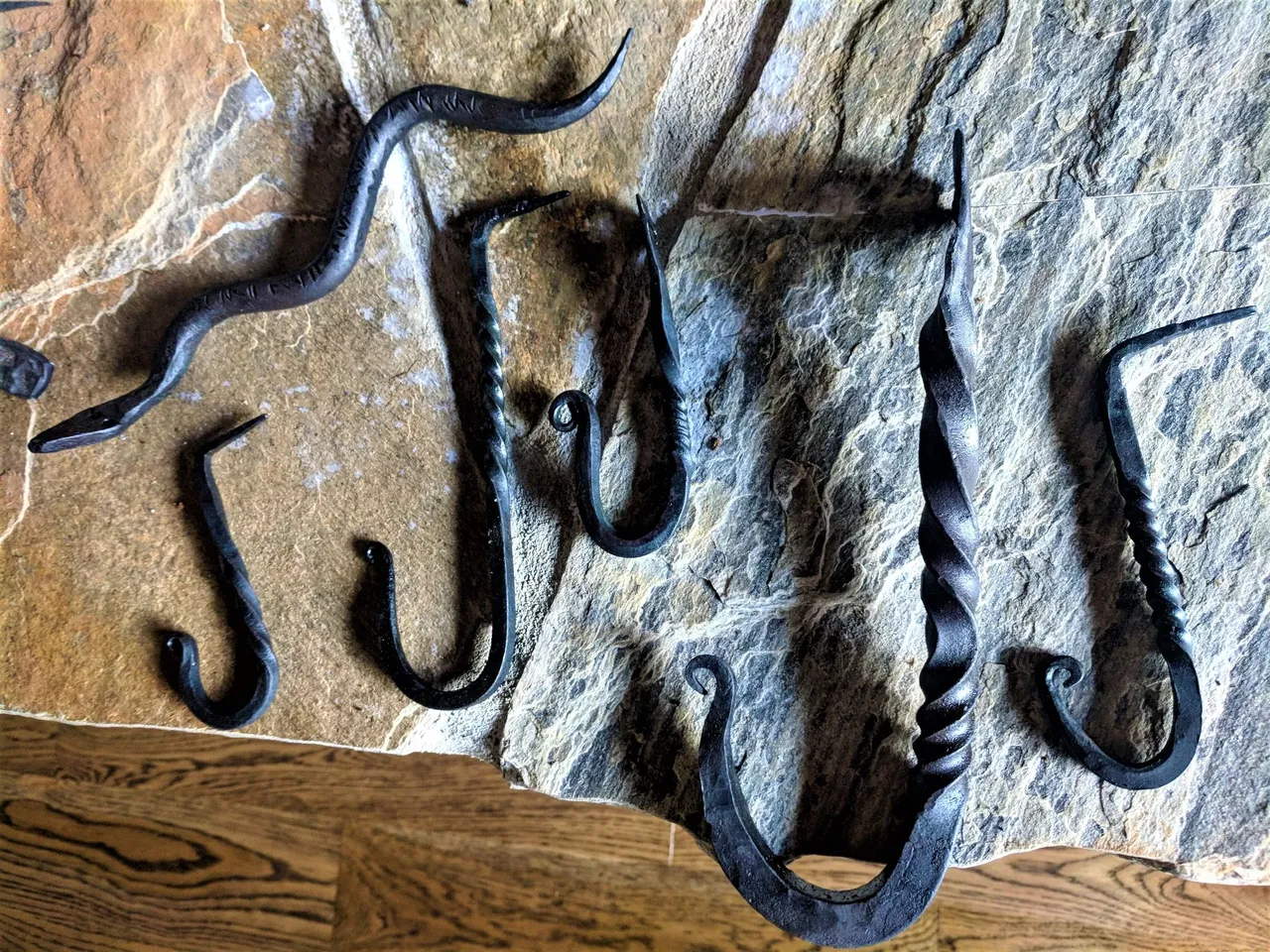

Our first mini project was to learn to make hooks. I couldn't believe it, that's exactly what @qberryfarms had asked me to make her when I left for blacksmith class. I thought, yeah right, we'll probably not get to make whatever we want. As it turns out, hooks are the perfect first project for blacksmiths because it entails all the basics you need to know. We took a section of square steel 1/4 inch wide and about a foot long and first heated one end in the forge until it was glowing orange. Hammering the end while turning it with our other hand tapered off one end and drew it out longer. Then we learned to heat it up just right in order to twist the rat tail tip and bend that over into a hook. On the other end we bent it at 90 degrees after tapering it off into a sharp point to use it as the nail. I can't explain how satisfying it is to make something than will most definitely outlive me.

Each day was strewn with new an interesting facts I had never heard before as well. Our master blacksmith teacher was Bryan Fritts and he was full of interesting information. Right away he told us of the importance of the anvil and gave us information on the various ones in the blacksmith shop. For instance he showed us how most anvils will ring loudly when you hit them with a hammer. Then stepping up to this one anvil and he hits it. It just makes a sort of thud sound with no ring. Bryan explained that during the civil war, blacksmiths were among the first to be killed to prevent them from working for the enemy. No army could survive without blacksmiths! The soldiers in enemy territory would listen for the sounds of a blacksmith and immediately hunt him down and kill him. So during the civil war anvils were created with different metal properties so that they would not create a loud ring. I thought this was fascinating.

I ended up making a lot of hooks, each one different than the others. I began adding twists in the square tube steel to add some details and moved up to using much larger steel like 1 inch square tubing blanks. For me this was even more fun and rewarding because you have to hit it as hard as possible to make it move much. By the end of the last day I had made a plant hanger, many hooks, a cool blacksnake for my artsy piece and an herb hook. The herb hook still needs to have a hole drilled through it and a rivet installed. Bryan showed me how to make my own rivets from a piece of round bar steel and using my torch to heat it read hot. I'll do this at home to finish that piece.

This old home made power hammer is very cool, power by your foot stomping on it

This old home made power hammer is very cool, power by your foot stomping on it

All in all it was so enjoyable to me that I've been thinking of the best way to make my own forge to use on the farm. Believe it or not the anvil is the hardest to find and most expensive. Although you can find smaller lighter ones even on Amazon for a few hundred dollars, a real full size anvil can easily approach $1000! I had no idea, but the average price is $4 per pound and many anvils can weigh 300 lbs. The forge could be easy to build. You just need a good metal table, a blower and something to use as the main bowl to hold the hot coal. We were told and old brake drum makes the best base for the coals since it also has a holes in the bottom for a blower to blow through and heat the coals.

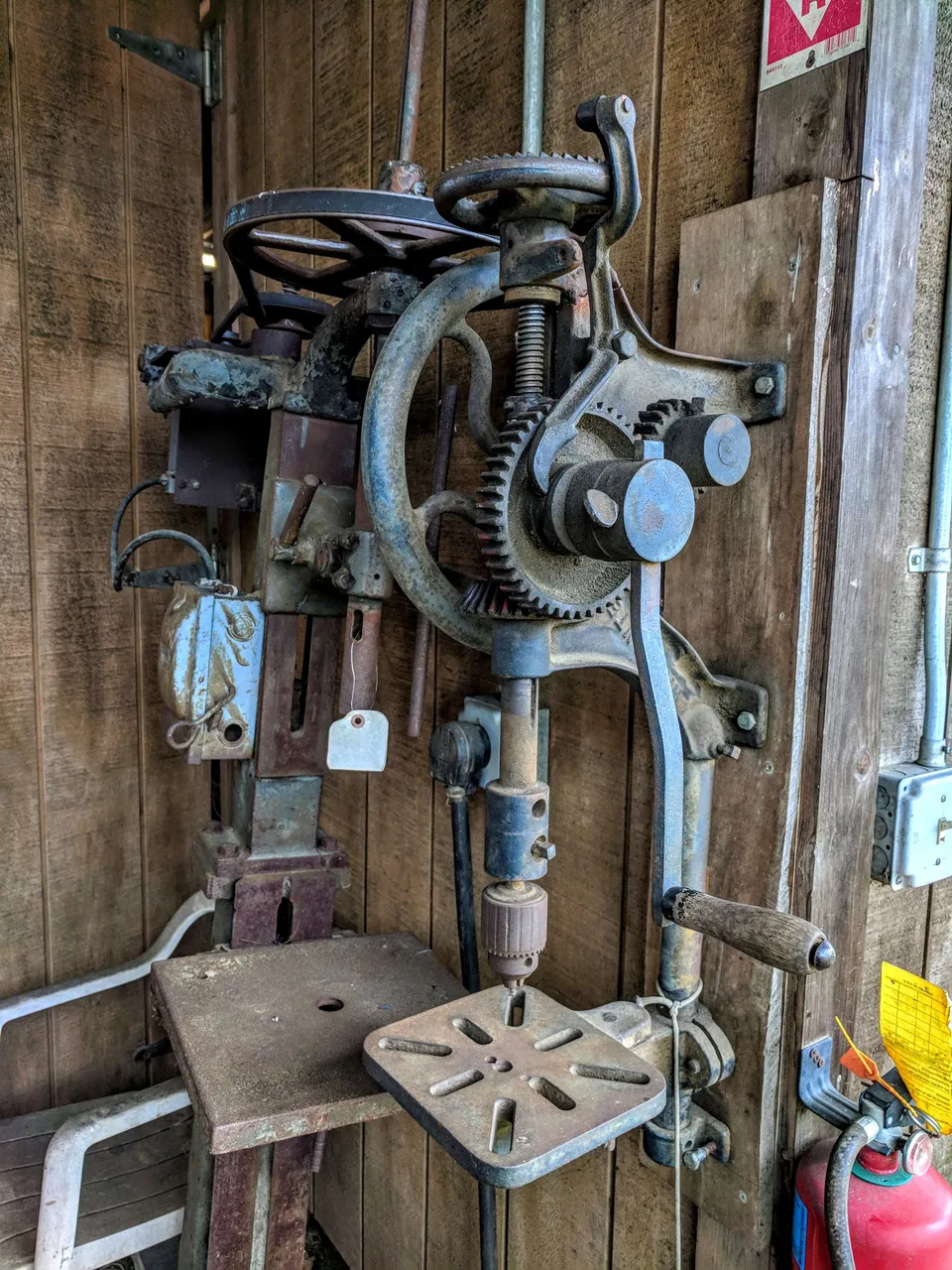

This hand cranked drill press was also very impressive

This hand cranked drill press was also very impressive

Now that I have completed an extensive welding class and this blacksmith class, I don't even know where to start with all the tools I want to get and things I'd like to make. I guess a welding machine comes first so I can use it to make a blacksmith forge. These forges are very handy for lots of work. If you ever need to bend or cut steel a forge is great for making that process much easier. Hopefully someday you'll see a post from me building a blacksmith forge! Next month is Forging class which is a continuation of blacksmithing and covers making your own metal to then build your projects out of. You just collect scrap metal like shell casings and broken tools and melt them down. Then you can shape them to whatever you desire. I'm really liking these old world arts and crafts. Oh and you ladies, don't let the manliness of the art fool you. We were told that quite often women make the best blacksmiths. Since ordinarily they do not hit as hard, they tend to do the most intricate and refined work.

Here are some of the hooks and the snake I made, and the herb hanger

Here are some of the hooks and the snake I made, and the herb hanger

This plant hanger was requested by @qberryfarms. It's sideways in the picture

This plant hanger was requested by @qberryfarms. It's sideways in the picture