3D printing, also called Additive Manufacturing, is the process of fabricating 3 dimensional solid objects from a digital file. It is achieved by laying down successive layers of material until the object is created. This technology has found many applications in different fields ranging from the manufacture of Jewelries, Firearms, in the Automotive industry, Archeology and Electrical engineering.

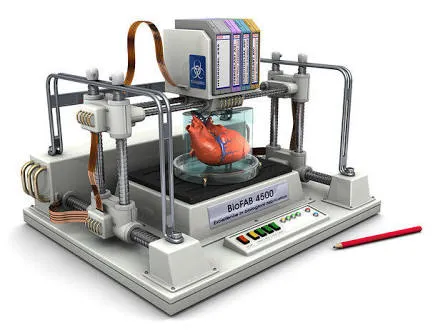

All these are however produced with inorganic materials. What about Biofabrication? Wouldn't it be awesome if working human tissues and organs could be printed? It would revolutionize the field of medicine wouldn't it?...... Well this is the reason behind 3D Bioprinting.

3D Bioprinting is the utilization of 3D printing and 3D printing like technique to combine cells, growth factors and biomaterials to fabricate biomedical parts that maximally imitate natural tissue characteristics. source

The layer by layer method used in 3D printing is also applied in Bioprinting where materials known as "Bioinks" are deposited to create tissue like structures.

A Bioink is a hydrogel biomaterials that can be extruded through a printing nozzle or needle into filaments that can maintain shape fidelity after deposition. source

Bioinks are known for their favourable biocompatible properties and are attractive biomaterials for cell encapsulation. They provide support for cells blended into them by providing an aqueous 3D environment with biologically relevant chemical and physical signs that mimic the natural extracellular matrix environment and support the adhesion, proliferation and differentiation of living cells towards the ultimate generation of a functional tissue.

Bioprinting Techniques

Depending on the deposition technique of the print head, Bioprinters are categorized into 3 types:

Ink-jet printers

Laser jet printers

Extrusion printers

Ink-jet printing

At its initial development in the 1970's, Ink-jet printing was just a 2D printing technique but with a modification in 1992, 3D printing, based in this technique was achieved. There are four approaches existing for Ink-jet droplet squeezing, which are the thermal, piezoelectric, acoustic and electrostatic Ink-jet printing. The thermal and piezoelectric are however the most widely utilized for structure fabrication.

An Ink-jet printer consist of an ink chamber with a number of nozzles. With the thermal printing approach, the bioink drops are ejected from the nozzles due to the high pressure of air bubbles generated by an integrated heating element.

Heat is used to create pressure in the thermal printing approach, but this is not the case in the piezoelectric printing approach. In the piezoelectric printing approach, a voltage pulse induces a charge on the piezoelectric material and ejects droplets out of the nozzle.

The Ink-jet technique offers advantages such a low costs and minimal contamination of the cells due to non-contact deposition technique, however, heat, mechanical stress and vibration could adversely affect the cell viability, clog the nozzles and make it harder to construct a multi-layer 3D structure.

Extrusion printing

This techniqueis considered to be the most adopted technique to date because it suits a wide range of Bioink viscocities, allows continuous deposition, Fast printing time and better structural integrity of the cells. It utilizes a pneumatic dispensing system for delivering the cells.

Drawbacks to this technique include limited material selection due to rapid cell encapsulation and increased shear stress resulting in more cell injuries.

Laser jet printing

This technology can work with high viscosity Bioinks such as hydrogel and provide a higher degree of precision. It utilizes the energy of a laser pulse to create the actuation bubble, ejecting the cells onto a substrate.

Drawbacks of this technique are the relatively long printing time and a higher rate of damaged cells due to the heat generated from the laser.

The Bioprinting processes

Bioprinting generally starts with creating a 3D model to print, selection of the corresponding cells for a tissue and preparing a viable Bioink from a suitable cell carrier and media. Creating a 3D model for Bioprinting is done by Computed Tomography (CT) scan and Magnetic Resonance Imaging (MRI). This is quite similar to creating a 3D model from a 3D modeling software or based on data generated with a 3D scanner. The above process is part of the Pre-Bioprinting stage, next is the Bioprinting stage.

In this stage, bioink spheriods each containing an aggregate of tens of thousands of cells are injected into a layer of water based Bio paper made from collagen, gelatin or other hydrogel. Successive layers are continually added until the tissue is built. As this happens, nature takes its course and the Bioink spheriods slowly fuse together and the Bio paper dissolves away or is otherwise removed.

After the Bioprinting stages, comes the post Bioprinting stage which comprises of the necessary procedures to transform the printed construct into a functional tissue engineered organ, suitable for surgical implantation. In post Bio printing, a Bio reactor is an important tool for tissue engineering as it is able to provide a dynamic environment for tissue maturation and also plays a pivotal role in scaling up Bio printing.

Drawbacks to the use of Bioprinted Tissues and/or Organs

Bioprinting holds many promises for the future, but despite its innumerable number of advantages, this technology is not without it's fair share of drawbacks. Some of them are listed below:

Functionality: Printing a tissue and/or organ may sound really cool, but the Big Question is: "Does it function like its supposed to?".

If the organ printed does not function like it is supposed to, we would be justified to say it's pretty useless wouldn't we?Integration into the host's body: It is not enough to produce a functional tissue and/or organ, this lab produced tissue and/or organ must be able to integrate properly with the host body system or else it would not work right and would probably lead to the death of the organ or of the host.

Vasculature: Organs / tissues need nutrients to stay alive and these nutrients come from the blood stream. Typically when printing a tissue or organ in a lab, the Bioengineer creates a product that is not vascularized, and without vascularization, the organ/tissue would never survive.

Accessibility/cost: Making functional Organs via Bioprinting is very labour intensive and expensive. This brings us to the big issue of it being accessible to patients who lack financial resources.

References

Reference 1

Reference 2

Reference 3

Reference 4

Reference 5

Thank you for reading!