What is crude oil,

and what is it used for?

Crude oil is pumped from the ground in the Middle East (e.g., Saudi Arabian Arab Light), West Africa (e.g., Nigerian Bonny Light), the Americas, and Asia (Russia), pumped into ships called tankers, and sailed across the ocean to oil refineries on the Delaware River.

Refining is the complex series of processes that manufactures finished petroleum products out of crude oil. While refining begins as simple distillation (by heating and separating), refiners must use more sophisticated additional processes and equipment in order to produce the mix of products that the market demands. Generally, this latter effort minimizes the production of heavier, lower value products (for example, residual fuel oil, used to power large ocean-going ships) in favor of middle distillates (jet fuel, kerosene, home heating oil and diesel fuel) and lighter, higher value products (liquid petroleum gases (LPG), naphtha, and gasoline).

The uses and benefit of crude oil

The uses and benefits of crude oil are numerous and the world would be a different place without it. Crude oil has been used in many of the advancements that have occurred over the past century and a half and continues to bring benefits to the world. It important to understand the uses and the benefits of crude oil and its products.

The uses of crude oil product

Crude oil exists as a liquid that rests in various formations deep within the Earth’s crust. This liquid forms as a result of the decomposition of organic material that dates back millions of years. If you break down its chemistry, you would find crude oil is a mixture of complex hydrocarbon molecules and other organic compounds. Another name used for this material is petroleum, though that term also refers to products made from refined material itself.

Once extracted, crude oil undergoes distillation. This process breaks the liquid down into various products of different weight, depending on the exact composition of the liquid. The largest share of crude is used for energy carriers that can be combined into gasoline, jet fuel, diesel, and heating oils.

Heavier products are used to make tar, asphalt, paraffin wax, and lubricating oils. Various chemicals can be derived from the liquid as well, including sulfur, petroleum coke, and petrochemicals. Besides the products directly derived from the crude oil, there are over 6000 items derived from petroleum byproducts. Some examples include fertilizer, perfume, insecticides, soap, and vitamin capsules.

The benefits of crude oil products

There are thousands of products that modern Americans enjoy that come directly or indirectly from crude oil. These products have transformed the quality of life of Americans and people around the world.

Crude oil generates heat. Heating this material and other petroleum products can warm homes in colder weather, making modern living possible even in colder climates. This oil also produces energy. Many petroleum products are energy carriers. When burned, the energy is released and can be harnessed for various products, like gasoline, diesel, and jet fuel.

This product makes machinery move by providing the lubrication oil that modern industrial equipment depends on to run smoothly. Crude is also used to create the asphalt that cars and trucks move on. Asphalt is easier to lay than concrete and is generally cheaper as a result.

Petroleum provides the ingredients that are essential in products like soaps, detergents, and paints. This product also makes modern furniture manufacturing possible. It takes about 16 gallons of crude oil to produce a typical modern sofa. Crude is also an integral part of modern textile production, with 40 percent of textiles now containing some petroleum by-product.

THE PROCESS OF CRUDE OIL REFINING

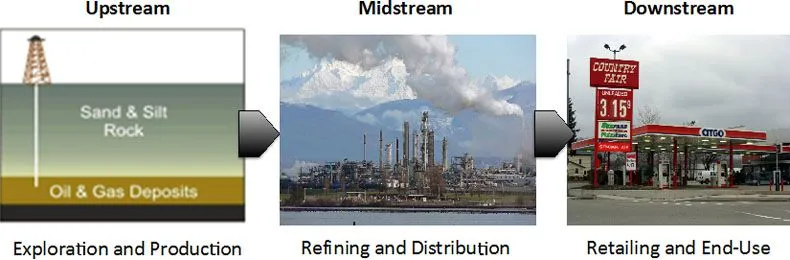

Once crude oil is extracted from the ground, it must be transported and refined into petroleum products that have any value. Those products must then be transported to end-use consumers or retailers (like gasoline stations or the company that delivers heating oil to your house, if you have an oil furnace). The overall well-to-consumer supply chain for petroleum products is often described as being segmented into three components (shown graphically in Figure 2.1).

Upstream activities: involve exploring for crude oil deposits and the production of crude oil. Examples of firms that would belong in the upstream segment of the industry include companies that own rights to drill for oil (e.g., ExxonMobil) and companies that provide support services to the drilling segment of the industry (e. g. Halliburton)

Midstream activities: involve the distribution of crude oil to refiners; the refining of crude oil into saleable products; and the distribution of products to wholesalers and retailers. Examples of firms that would belong in the midstream segment of the industry include companies that transport oil by pipeline, truck or barge (e.g., Magellan Pipeline); and companies that refine crude oil (e.g., Tesoro).

Downstream activities: involve the retail sale of petroleum products. Gasoline stations are perhaps the most visible downstream companies, but companies that deliver heating oil or propane would also fall into this category.

Figure 2.1 Well-to-consumer supply chain for petroleum products. Upstream midstream and downstream

Some companies in the petroleum industry have activities that would fall into upstream, midstream and downstream segments. ExxonMobil is one example of such a firm. Others have activities that fall primarily into only one segment. The KinderMorgan pipeline company is an example of a specialized petroleum firm, in this case belonging to the midstream segment. Many regions have local gas station brands that would specialize in the downstream segment of the industry. One of the best-known regional examples is the WaWa chain of gas stations and convenience stores in eastern Pennsylvania, but large grocery stores and retailers like Costco and Wal-Mart are increasingly involved in downstream sales of petroleum products.

Petroleum refineries are large-scale industrial complexes that produce saleable petroleum products from crude oil (and sometimes other feedstocks like biomass). The details of refinery operations differ from location to location, but virtually all refineries share two basic processes for separating crude oil into the various product components. Actual refinery operations are very complicated.

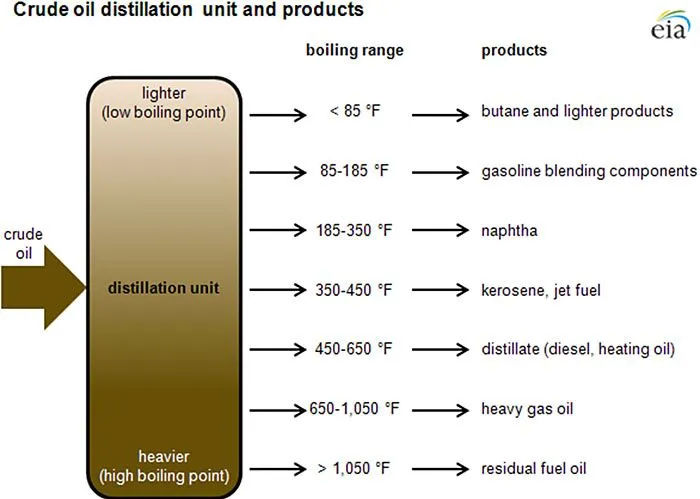

The first process is known as distillation. In this process, crude oil is heated and fed into a distillation column. A schematic of the distillation column is shown in Figure 2.2. As the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions.” The fractions are then captured separately. Each fraction corresponds to a different type of petroleum product, depending on the temperature at which that fraction boils off the crude oil mixture.

Figure 2.2: Crude Oil Distillation

Credit: EIA

![2.03.jpg]!

![2.03.jpg]!

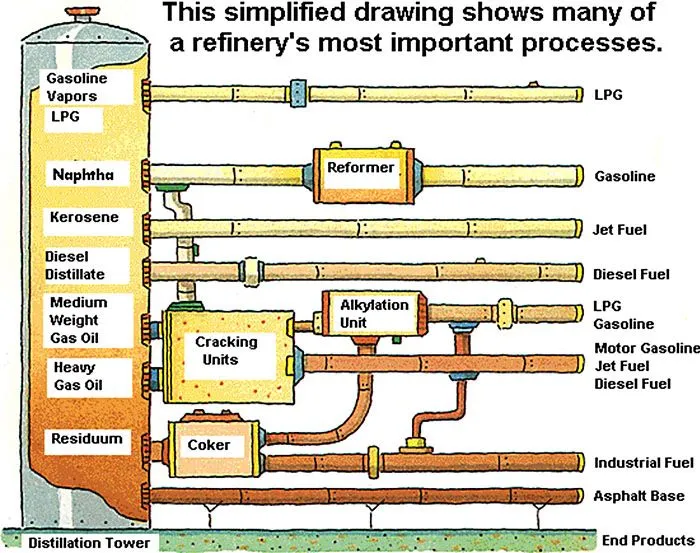

Figure 2.3: Important processes of a refinery

Credit: EIA

The second process is known as cracking and reforming. Figure 2.3 provides a simplified view of how these processes are used on the various fractions produced through distillation. The heaviest fractions, including the gasoils and residual oils, are lower in value than some of the lighter fractions, so refiners go through a process called “cracking” to break apart the molecules in these fractions. This process can produce some higher-value products from heavier fractions. Cracking is most often utilized to produce gasoline and jet fuel from heavy gasoils. Reforming is typically utilized on lower-value light fractions, again to produce more gasoline. The reforming process involves inducing chemical reactions under pressure to change the composition of the hydrocarbon chain.

The production of final petroleum products differs from refinery to refinery, but in general the oil refineries in the U.S. are engineered to produce as much gasoline as possible, owing to high demand from the transportation sector. Figure 2.4 shows the composition of output from a typical U.S refinery.

2.04.jpg]( )

)

Figure 2.4: Products made from crude oil

Credit: EIA

Nearly half of every barrel of crude oil that goes into a typical U.S. refinery will emerge on the other end as gasoline. Diesel fuel, another transportation fuel, is generally the second-most-produced product from a refinery, representing about one-quarter of each barrel of oil.

REFERENCES

•www.e-education.psu.edu

•www.kendrickoil.com