Sincerely your best friend steemit.

Speaking of coconuts, I think we all know that coconut fruit is one of the many fruits grown on the coast. This fruit is widely consumed at the time of young age with physical characteristics of green. In addition to the delicious taste it is also beneficial for health to restore the body ions when consumed after the activity.

Coconut fruit is a plant in Palmae family that is very commonly found in the tropics, especially in coastal areas. Coconut is very popular in the community because it has many benefits for human life and can be said to be versatile and zero waste because almost all parts of this plant can be utilized by humans. Various benefits are obtained from the fruit, water, fibers, shell, leaves and stems.

On this occasion I will talk more specifically that coco fiber and its role in the application of construction technology.

Concrete as a construction material is not only composed of cement, sand, gravel, and water but also an additive (admixture) which can improve workability, compressive strength, tensile strength, flexural strength, slow or accelerate the initial tie time and so on, as needed. The addition of other materials, especially natural fibers in the normal concrete certainly has its own way of analysis. The addition of fibers in certain proportions is likely to affect the behavior of the whole concrete structure. The effect of this change needs to be examined to provide precise information on the behavior and capacity of fibrous concrete in particular the fibers of coconut fibers.

According to Wikipedia,

Concrete fiber is a concrete that way of making plus fiber. The purpose of adding these fibers is to increase the tensile strength of the concrete, so that the concrete is resistant to tensile forces due to weather, climate and temperatures that usually occur in concrete with a large surface. The types of fibers that can be used in fiber concrete can be natural fibers or artificial fibers.

Coco fiber is durable, very ductile, strong against friction, not easily broken, resistant to water, not easily rot, resistant to fungi and pests and is not inhabited by termites and rats.

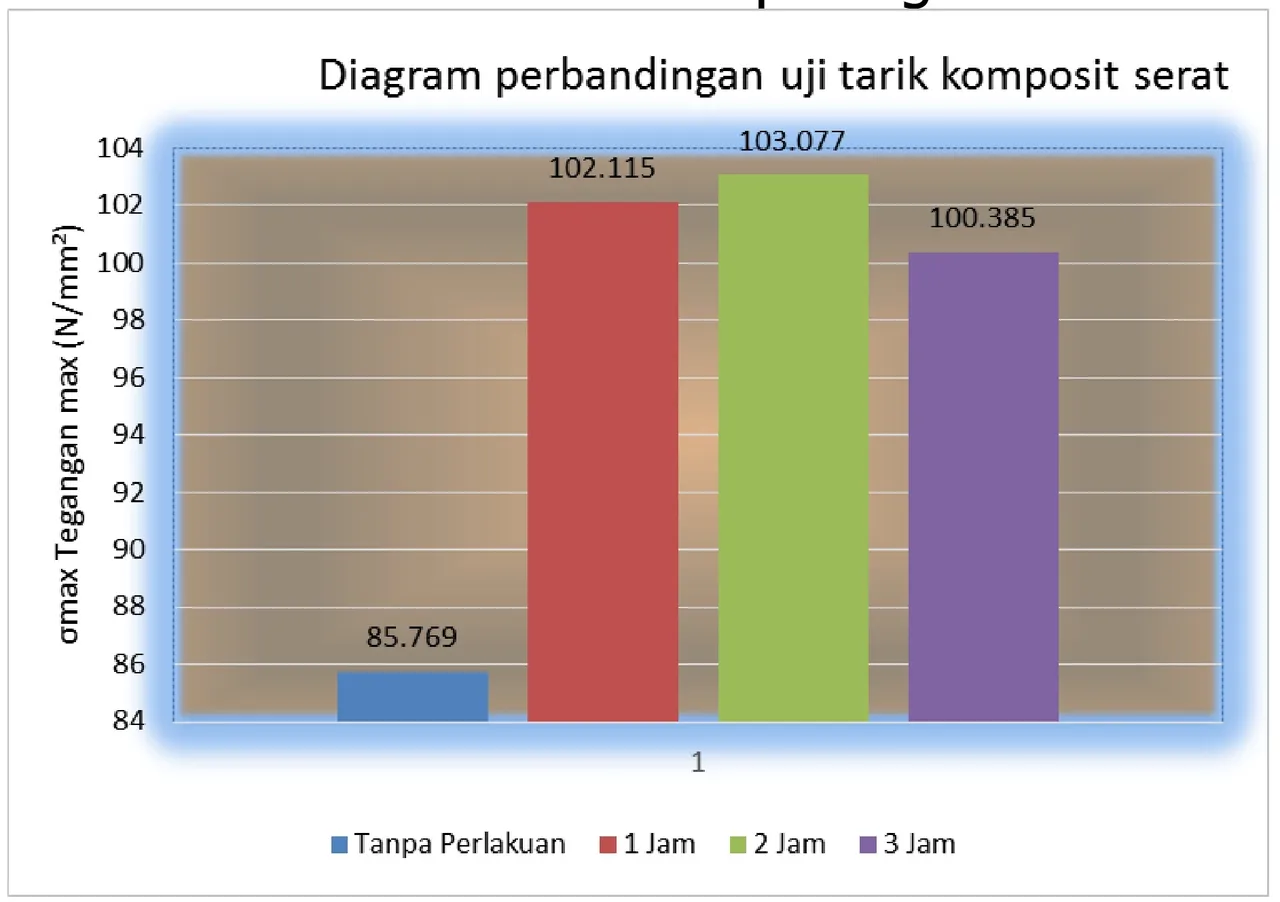

Ilyas Renreng and Abdul Hay Muchsin are researchers at the Department of Mechanical Engineering, Faculty of Engineering, Hasanuddin University of Indonesia in their mechanical journal "Cocos Nucifera Tensile Strength With Curcuma Domestica Treatment" stated the test results show that composite tensile test, each varieties were tested 1 times, best result obtained in composite specimen with 80% fiber composition: 20% resin with 2 hours pretreatment fiber. Where the average maximum tensile load is more than 5360 N. Read more here.

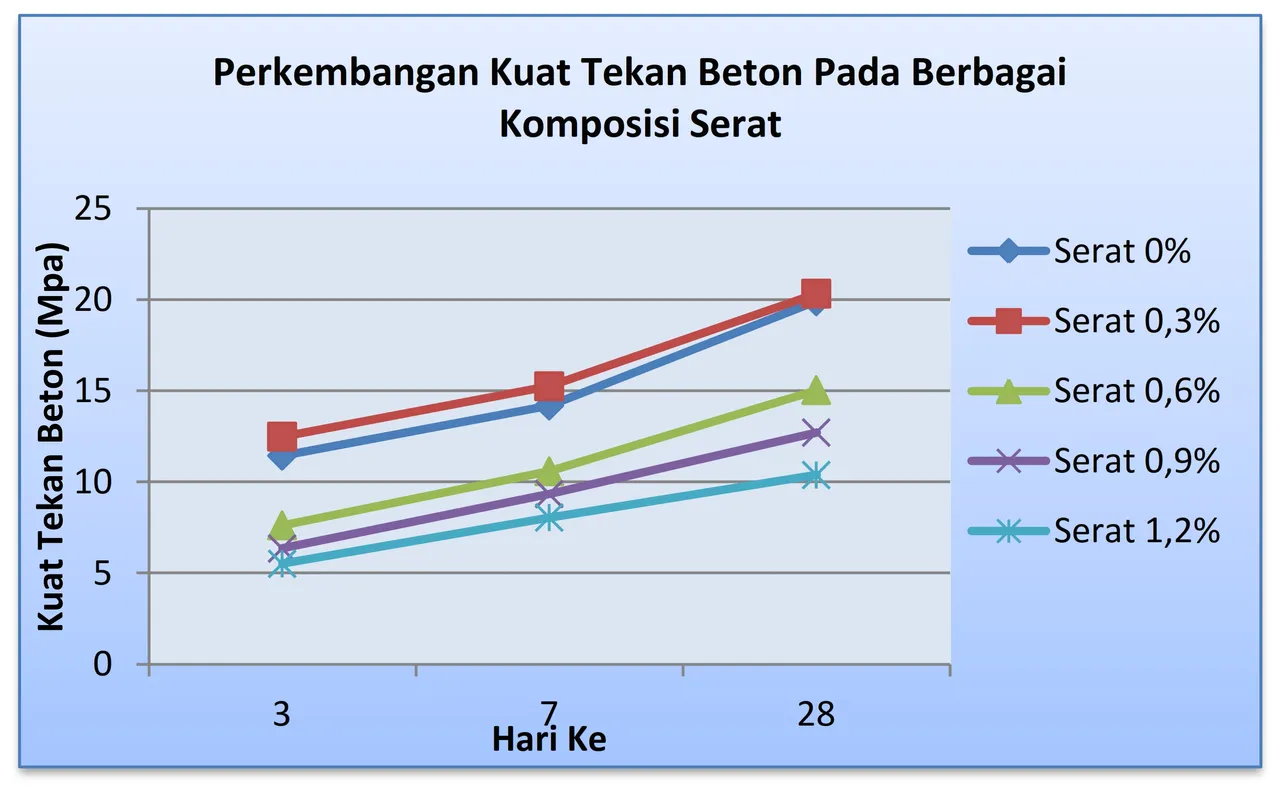

Romy Talanipa, a researcher and faculty member of the civil engineering department of the University of Haluoleo Indonesia's technical faculty in his journal "The Effect of Addition of Coconut Coir Fiber Against Strong Concrete Press on Normal Concrete" stated that the results showed that with the addition of fibers of coconut fiber to the volume of concrete with a certain percentage increase value compressive strength on concrete. Read more here.

With the addition of coco fiber on the concrete can increase the compressive strength of concrete that is obtained by compressive strength of the optimum in the proportion of fiber addition with a certain value where it exceeds the normal concrete compressive strength but not too significant.

I HOPE YOU ENJOY READING

Reference :

https://id.wikipedia.org/wiki/Beton_Serat

https://id.wikipedia.org/wiki/Sabut

http://jurnal.untad.ac.id/jurnal/index.php/Mekanikal/article/download/5257/4011.

http://ejournal.kemenperin.go.id/jrti/article/view/2698