Today, our hazard Identification is MECHANICAL

Talking about Mechanical Hazards, we are referring to the energy contained in the components of a mechanical system that could make such a system hazardous, i. e., rotation, vibration, or motion within an otherwise stationary piece of equipment or machinery. Examples include:

- Rotating equipments

- Compressed springs

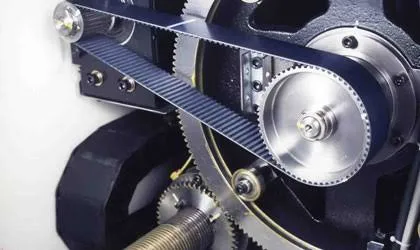

- Drive belts

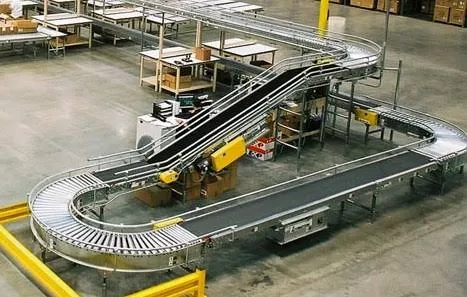

- Conveyors and

- Motors

Mechanical hazards are inherent in the following:

Automated guided vehicles, Robot moving parts, rotating moving parts, belts chains, couplings, connecting rods, gears, cams, flywheel, pulley, conveying pallets or conveyor belts, packaging, winding web, coating, stretching, forming of stock, drilling, shaping, cutting /slitting.

Mechanical hazards can lead to:

- Crushed hands and arms

- Injured fingers and foot

- Blindness

- Permanent disability

- Amputated limbs

- Fracture

- Laceration

- Scar and even death.

Your ability to recognize Mechanical Hazards is the first step to preventing/avoiding incidents resulting from them. Also, putting Mechanical safeguards in place can help to prevent workers from getting injured

You are advised to always follow approved procedures for calling emergency medical personnel and for reporting injuries in your workplace. Always follow machine operation instructions before operating any machinery. This can help reduce the risk of injury by properly explaining how to operate it and how to recognize malfunctions. You need to follow the machine’s operating instructions and ensure that the machine is being run correctly and safely. This includes all machine safety features and guards.

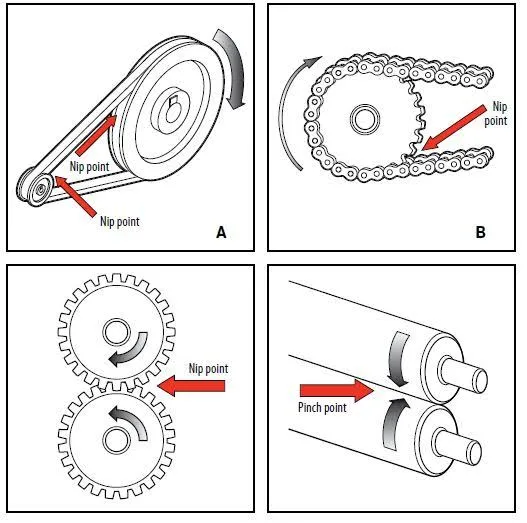

When working with mechanical devices be mindful of:

- Points of operation

- Pinch points

- Nip points

- Shear points

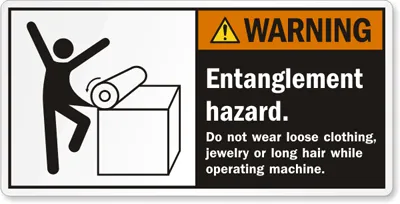

- Being drawn in when a rotating machine catches your hair or clothing

- Your hand or arm been forced into dangerous positions causing lacerations, broken bones or amputation

- Projections on rotating components which can strike the operator

- Entanglement

- Getting struck by or caught between the stationary part and the moving part of the up-and-down or back-and-forth motion of the machine.

You are advised to always ensure that proper isolation is in place before carrying out maintenance job on Mechanical devices. Also, do not remove guards put in place by the manufacturer. If for maintenance purposes the guards are removed, remember to put the guards back in place before putting the machine back in service.

Finally, always use correct Personal Protective Equipment (PPE) when working with machines.

As you carry out your duties today both at home or in your work place, especially in high risk job environments like offshore drilling rigs and construction sites, be mindful of mechanical related hazards. Always ask yourself "what if?" "How can I get hurt in the task I'm currently carrying out?" Be very conscious of your environment. Train yourself to have a high sense of situational awareness.

"STAY ALERT, AND STAY ALIVE!"

-Shalom!

Reference: (eLCOSH : Chevron's Dropped Object Prevention Program)

Google images

Sheakley (the human resource people)

Thecollectivephilanthropist (Slides hare)

I hope you found this piece of information useful. If you did, please UPVOTE , RESTEEM and FOLLOW ME for more.

@nathanieloamhen (NEBOSH™ certified Occupational Health and Safety practitioner)