Are you interested in Japanese sake?

Why don’t you come to Niigata Prefecture, the heartland of Japanese sake making, and go on a tour of an award-winning sake brewery where you will have the opportunity to see, taste, smell, and participate in all three stages of the sake brewing process?

What to Expect

Japanese sake relies on cold temperatures to produce the kind of fermentation that leads to good flavors, so it is best to visit sake breweries in the winter. Since most breweries tend to be nestled in mountainous areas known for massive amounts of annual snowfall, you can expect to be cold during parts of your tour, the temperature inside much of the brewery being equal to the temperature outside.

In addition, you can expect to be entertained. Japan has a very strong hospitality culture and knows how to welcome and entertain its visitors very well. During your tour, you are sure to be offered food, gifts, unexpected opportunities, and a never-ending stream of enthusiastic and humorous conversation.

Kaetsu Brewery

This is where the process of making sake begins. Premium-grade rice, which has been engineered to have large grains, is polished. That means that the bran on the outer edge of the rice kernels is ground away, sometimes leaving as little as 30% of the kernel behind to be used in the sake brewing process.

After the rice has been polished, it must be washed, soaked, and steamed. Steaming the rice, as opposed to simmering it in a pot of water, reduces the water content of the prepared rice and helps to preserve the integrity of the cooked kernels, two things that are essential to controlling the quality of the sake flavor. Prepared rice that has a high water content spoils easily, and kernels that become cracked produce inferior sake flavors.

Cooling the Rice

After the rice has been steamed, it is immediately cooled. Here, you can see rice being cooled in the traditional way, by spreading it out on mats that have been laid on a concrete floor in a cold room. On the Kaetsu brewery tour, you can participate directly in this step of the brewing process.

Once the temperature of rice has dropped to the desired temperature, it can be inoculated with a specific type of mold to make koji, a crunchy type of fermented rice that smells and tastes something like a sweetened Camembert cheese rind.

Making koji is, perhaps, the most important part of the sake brewing process. It is done by hand in a warm room, the temperature and humidity of which are carefully controlled.

While participating in the making of koji isn’t part of this brewery tour, one is given the rare opportunity to enter the room where the koji is made and see the tools that are used in its preparation.

Making the Starter

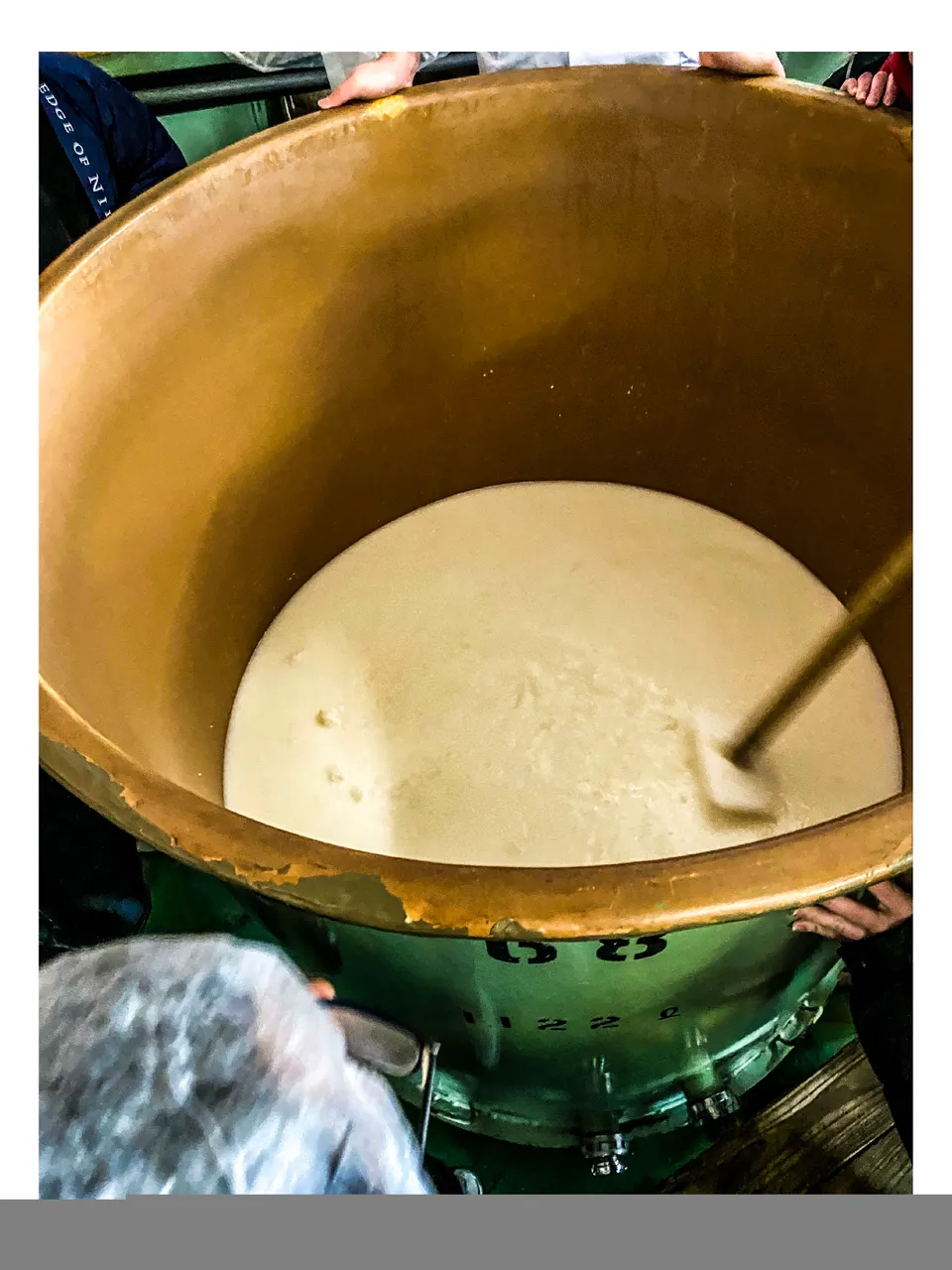

To begin the fermentation process, a starter must be made. This is done by combining water, yeast, steamed rice, and koji (mentioned above) in a container. Again, here, rice is freshly steamed, cooled, and only after it has dropped below a specific temperature, added to the mash, which is then mixed with wooden paddles.

What is unique about sake mash is that two chemical processes occur at once. The mold that was used to make koji converts the starch of the rice into sugar, and the yeast that is added to the mash converts that sugar into alcohol, which results in a higher alcohol content than that found in beer and wine.

Wouldn’t you like to try your hand at heaving a large mound of steamed rice into a cauldron of water, yeast, and koji, and then pushing it around with a long wooden paddle?

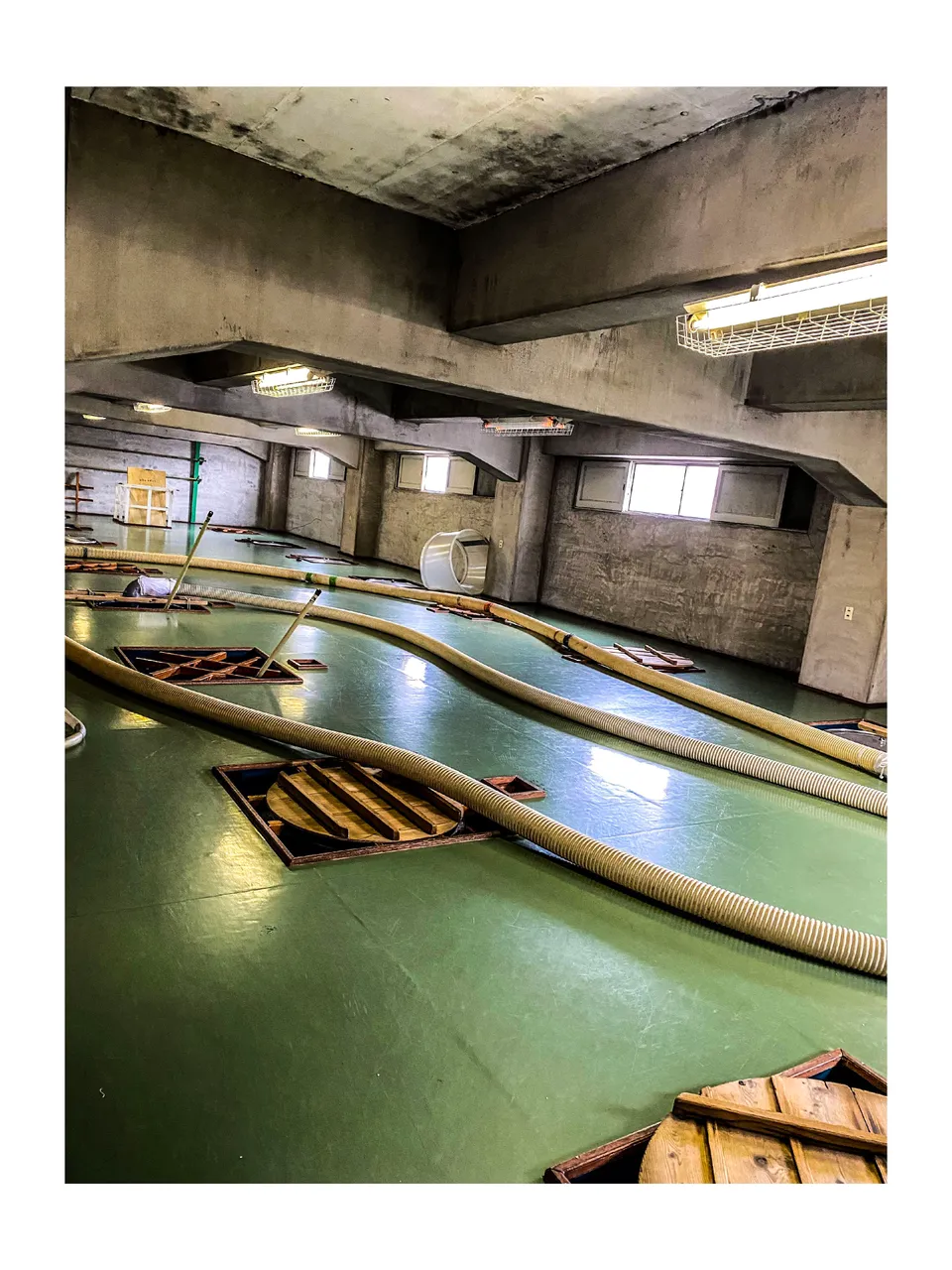

Fermenting the Mash

These are the fermentation vats, large containers laid under the floor, where mash is mixed with yet more rice, more koji, and more water. This is done over the course of a few days in three stages, each of which generally doubles the size of the mash. After the third and final stage, the mash rests and ferments for anywhere between 18 to 32 days. During this time, its temperature and its physical properties are measured and adjusted to produce the desired flavor profiles of each sake.

In this picture, you can see steamed rice being blown into the mash via a vacuum hose and stirred with a traditional wooden paddle.

The End of the Tour

Now that you’ve seen the sake making process from start to finish, what could be left? Sampling the sake, of course.

At Kaetsu’s brewery tour, participants are given two hours to sample twelve different varieties of sake and a number of hors d’oeuvres at their leisure. In addition, tour participants are also given a large Japanese lunch to freely experiment with a variety of original sake/food pairings.

After spending an hour walking through a cold concrete building, one couldn’t ask for a better way to end the tour, warming oneself from the inside out with amazing sake and delicious food!

For more information on Niigata tours, please be sure to visit Edge of Niigata.