There is no doubt that the need to change our means of transportation for emission-free systems, coupled with the need to achieve the decarbonization of the energy industry, to curb CO2 emissions into the atmosphere, will lead to an incredible transformation of the current energy system based on fossil fuels, in one that is more sustainable. And in the search for a means to power our mobility, hydrogen has been targeted, but due to its explosive nature, storing hydrogen for use in mobile applications is a major problem.

However, recent advances in handling hydrogen as a liquid organic hydrogen carrier (LOHC) could make possible the vision of mobility without greenhouse gas emissions by powering means of transportation with hydrogen, but avoiding the danger of having to handle large quantities of gaseous hydrogen. And the Fraunhofer HHI is already working on solutions for the first hydrogen-powered train.

Perhaps soon rail transport will be powered by hydrogen. Source: edited image, original from pixabay.com.

Hydrogen transport using liquid carriers

Hydrogen is emerging as an important energy carrier, that is, a substance capable of storing energy and releasing it at another time and place, thanks to new methods that allow it to be obtained in a sustainable manner. However, hydrogen has a very low energy density per unit volume, so when large quantities are contemplated, better ways must be found to move it than compressed or liquefied. And one viable way is liquid organic compounds.

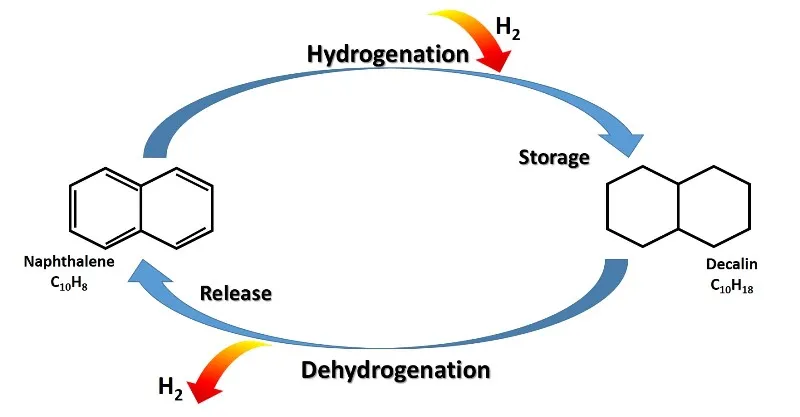

Liquid organic hydrogen carriers, better known by their acronym LOHC, are systems composed of organic substances that can absorb and release hydrogen through chemical reactions.

Basically the system is composed of pairs of substances of organic nature, one hydrogen-poor and the other hydrogen-rich, in which hydrogen can be stored by repeated cycles of hydrogenation and catalytic dehydrogenation.

The schematic illustration of decalin/naphthalene LOHC system. Source: image elaborated in powerpoint.

Any unsaturated organic compound can be used as a carrier liquid, which can be hydrogenated, i.e. chemically bonding hydrogen to this substance. The resulting compound can then be handled using the existing infrastructure for handling fuels such as gasoline and diesel; and when the hydrogen is needed, for example for use in fuel cells, the carrier liquid is dehydrogenated again in a dehydrogenation reactor containing a catalyst specially designed for this process.

Reaction catalysts for LOHC

This is the crucial point for the development of LOHC systems, to properly choose the catalyst for the hydrogenation and dehydrogenation reactions. Generally, active catalytic systems with a catalyst loading of metals such as platinum, palladium, ruthenium and rhodium have achieved acceptable kinetics at temperatures below 150 °C, However, the achieved stability, recycling and practical advantages have driven the use of heterogeneous catalyst systems, some of the most commercial ones being platinum-palladium systems on alumina, but the most relevant criterion being the efficiency of the catalyst, alternatives are still being investigated using different approaches.

In this context, the Fraunhofer Heinrich Hertz Institute (HHI) and the Helmholtz Institute Erlangen-Nuremberg (HI ERN) have developed an efficient and stable surface catalyst for hydrogen release from carrier liquids and used rail transport as an application case.

The research team succeeded in developing a system that brings the hydrogen release process to a reproducible and scalable level, and has also enabled them to increase the power density compared to conventional systems; and the backbone of this system is what they called the surface catalyst. The problem with conventional catalysts that use porous supports is that in mobile applications the mechanical resistance of the supports is not high enough, and they wear out very quickly, losing effectiveness.

And to solve the problem, this team structured aluminum plates using a femtosecond laser, which were coated with fine platinum dots, this plate offers a large internal surface that can even be enlarged between 7000 and 10000 times with this process.

Fraunhofer HHI is currently manufacturing other surface catalysts that will also be applicable for the construction of the first hydrogen-powered train, which is part of a larger project aiming at emission-free rail transport, as 40% of the German rail network is not electrified.

This system would make it possible to use the existing rail network to transport hydrogen-powered trains. Source: pxhere.com.

And LOHC technology is certainly a great alternative in this context, as replacing the entire rail infrastructure of a country is very costly, so the existing infrastructure could be used using hydrogen-powered locomotives.

Well friends, I hope you liked the information regarding this project to drive trains with LOHC technology. See you next time!

References

Rao PC, Yoon M. Potential Liquid-Organic Hydrogen Carrier (LOHC) Systems: A Review on Recent Progress. Energies. 2020; 13(22):6040.

Fraunhofer Heinrich Hertz Institute (2022). Fraunhofer HHI and Helmholtz Institute ERN develop catalyst technology for mobile use of liquid hydrogen storage systems.