More than three decades ago a radically new building material started gaining popularity - in Europe: The benefits of hempcrete (a.k.a. hemplime) include exceptional thermal performance, highly effective transmission of humidity, resistance to mould, and acoustic insulation. It is also fireproof, and sequesters more carbon than its industrial production requires. Given all these incredible benefits, it may sound surprising that until now hempcrete has been not been permitted in US building codes. This had to do with hemp being considered an illegal plant. With the legalization of cannabis for medical and even recreational use in many states, the US is finally ready to include hempcrete as a permitted material in its residential building codes.

image source

What is Hempcrete?

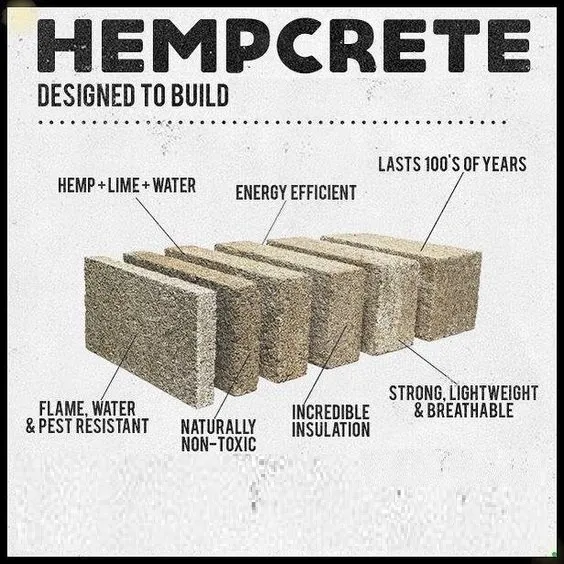

When separating the woody inner portion of the hemp stalk from the main fiber, we get what's called shives. They are also very fibrous, but unlike the main fiber, which is threaded into rope, shives are coarse, broken pieces. This material is what makes up the bulk of hempcrete. The other part is a limestone binder, using either hydrated or hydraulic lime. This is an industrial product, requiring the calcination of lime at very high temperatures in kilns, similar to the production of cement for concrete.

image source

After the hemp shives are mixed with the lime binder, and combined with the addition of water, the curing process starts. Depending on the type of binder, this could take up to a month. For this reason, the hempcrete is usually molded into blocks, similar to cinder blocks. In comparison, however, hempcrete tends to be lighter, and less brittle than concrete.

An Alternative to Concrete?

Before I continue comparing the characteristics of hempcrete to concrete, I want to get its most important drawback out of the way: Hempcrete has about 5% of the compressive strength of residential grade concrete. This means, it is never meant to be used as a structural material to bear great loads! However, excluding this main disadvantage, hempcrete outperforms concrete in so many other aspects, that it would be a waste dismissing this amazing material for its mere structural weakness.

First of all, hempcrete is not only highly insulative, but it also has a good thermal mass. Normally these would be contradictory properties, since most other materials with plenty of thermal mass tend to be poor insulators, and vice versa. Hempcrete is a great exception to this rule, due to its efficient R value of between 0.67/cm (1.7/in) and 1.2/cm (3.0/in) and a specific heat capacity of between 1000 J/kg K to 1700 J/kg K. At the same time, hempcrete "breathes", meaning it is great at transmitting humidity, keeping the interior air dry, which creates a comfortable warm sensation.

Other beneficial attributes of hempcrete are that it is fireproof, resistant to moulds, and is highly effective at insulating against acoustic disturbances. Its most notable feature, however, has to do carbon sequestration, making it highly interesting for modern applications, as we are facing an overabundance of carbon in our atmosphere.

https://static.wixstatic.com/media/43628e_9618359fcd1c4770bf40cd19cfc5cfc1mv2_d_3635_5452_s_4_2.jpg/v1/fill/w_954,h_472,fp_0.50_0.50,q_85,usm_0.66_1.00_0.01,enc_auto/43628e_9618359fcd1c4770bf40cd19cfc5cfc1mv2_d_3635_5452_s_4_2.jpg

image source

Carbon-neutral... or Carbon-negative?

Even before it is turned into hempcrete, the hemp plant is already highly effective at taking up carbon from the atmosphere. At 15 tons of CO2 per hectare it does this much faster than any forest or commercial crop, while it is fast growing and doesn't require much care or delicate conditions. So growing hemp is already a great way to combat CO2, but hempcrete takes this carbon sequestration a step further.

In its natural cycle, the hemp plant stops taking up carbon once it dies. Sure, by that time it will likely have reproduced, and its offspring can continue the good work, but in the form of hempcrete even the dead hemp plant can continue this process thanks to the lime binder it is mixed with. Due to the carbonation process, the lime continues absorbing CO2, not only during its curing phase, but throughout its entire existence. The amount of this is estimated around -1.6 to -79 kg CO2e/m2.

This means that even though the production of the lime binder involves a good amount of carbon emissions, it is all made up by the joint effects of growing hemp and converting it into hempcrete. So you could say that hempcrete is not only a carbon-neutral building material, but it is in fact carbon-negative, removing more carbon from the atmosphere than it has put into it.

Time to Start the Future?

Given its amazing properties, and time tested practicality in Europe, there are many ambitious projects related to hempcrete. One such proposed application are the Urban Sequoias, enormous high-rise buildings that are supposed to sequester 1,000 tons of CO2 per year, about the amount of 48,500 trees. Although no Urban Sequoia has been built so far, the technology is highly promising.

Also, now that the United States has incorporated hempcrete as a permitted material in its 2024 International Residential Code, it can be expected that this it will find further appeal and acceptance among builders, architects, and engineers in far reaching applications.