Hello everybody,

Here I am again, I will show the first part of making a 29er MTB bicycle steel frameset. I will show you each single step of mine 15th frame.

I said, "Hey, Joe, take a walk on the wild side."

I have written the past three posts in my language, which is Italian, and I will make a recap in English of what I have posted.

Tubeset will be half Dedacciai DR-ZeroUno and Columbus ZONA and dropouts from Paragorn Machine Works.

THE FRONT TRIANGLE

It is almost a century that all the bicycles are made mainly with 8 tubes:

- Head tube

- Seat tube

- Top tube

- Down tube

- A couple of chainstays

- A copple of seatstays

the front triangle is made by the head tube, the down tube, the top tube and the seat tube.

To do it I have to follow the dimensions and the angles from the drawings and I have to cut each tube in the right way and put it in the frame jig.

THE REAR TRIANGLE

this part of the frame is made by the couple of chainstays and seatstays and it is for sure the most complex part to do it.

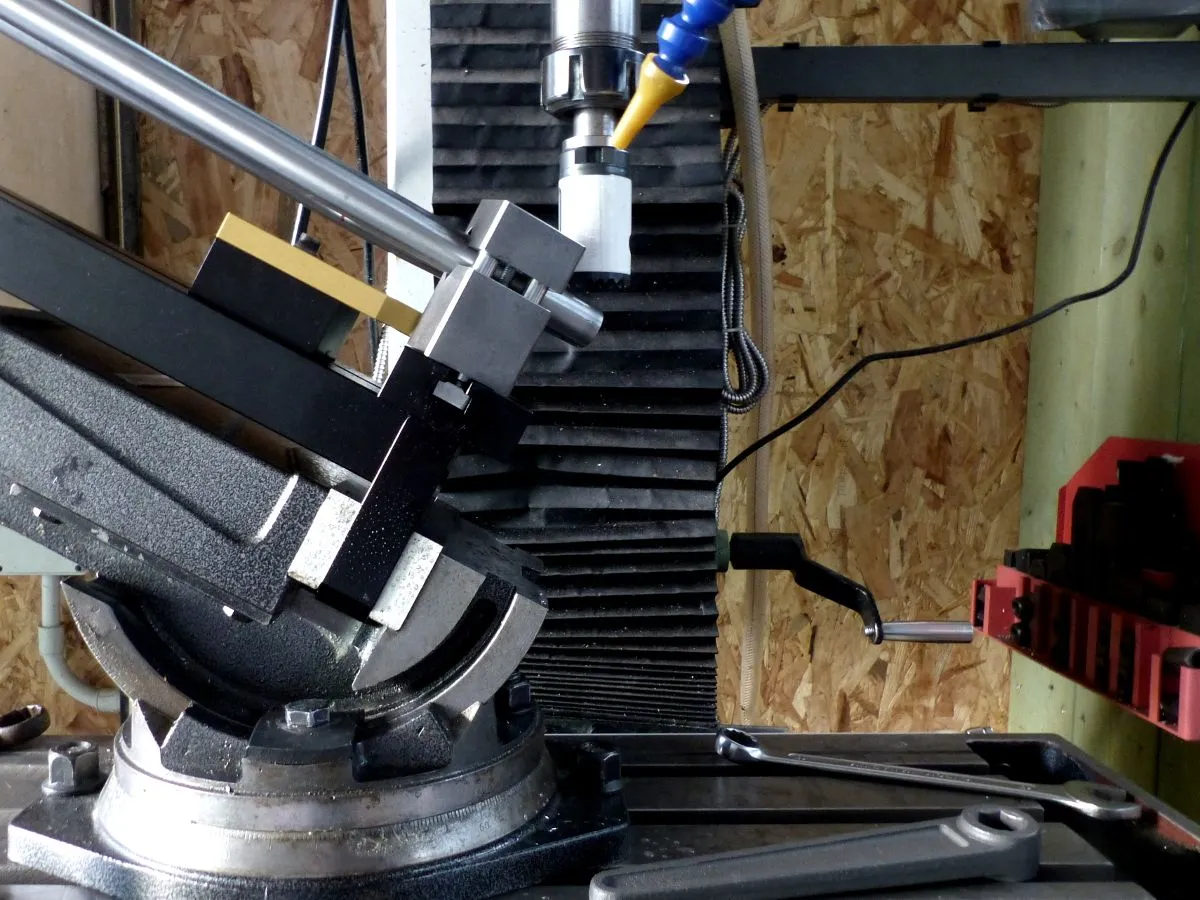

First of all I have to cut the chainstays with the proper jig and in the right position considering the wheel and the crankset clearance.

Then I have to cut the chainstays with another jig with the diameter of the seat tube.

At the end the result it is already pretty good and the frame looks fine.

DETAILS

Some parts are really difficult to do, but with the right process, it is possible to make them and in a good way.

I have understood something in the last years, the difference between handmade and industrial process. Handmade looks mainly to new ways, knowledges and beauty, sadly, the industrial process mainly stops the researches around profits or benefits.

I will continue with the much warm part of the framebuilding...

All the best,

G.