There are several types of battery thermal management systems integrated into EVs and HEVs from different manufacturers. Even though the overall outcome of those systems is almost same, which is maintaining a better thermal condition on vehicle battery packs, their functionality changes from one to another. Some of the well-known battery thermal management systems (BTMSs) are ,

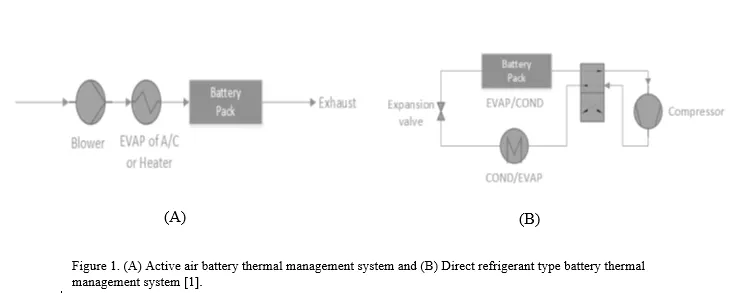

- Air BTMS - Air systems use air as the thermos transfer medium. The intake air could be direct either from atmosphere or from the cabin and could also be conditioned air after a heater or evaporator of an air conditioner (see Fig 1(A)).

- Liquid BTMS – Liquid type BTMSs use liquid as their thermos transfer medium. Mainly there are two types of thermal BTMSs. Dielectric liquid (direct-contact liquid) systems use a liquid which can contact the battery cells directly (mineral oil). Dielectric fluids do not interfere with the internal structure or the electrical operation of the battery so they can safely carry away the internal heat generated while the operation. Other type is conducting liquid (indirect-contact liquid) which can only contact the battery (mixture of ethylene glycol and water) cells indirectly, so they are used to externally carry away the heat generated.

- Direct Refrigerant BTMS - Similar to active liquid systems, a direct refrigerant system (DRS) consists of an A/C loop, but DRS uses refrigerant directly as heat transfer fluid circulating around the battery pack (see Fig 1(B)).

- Phase Change Material (PCM) BTMS - During melting, heat is absorbed by PCM and is stored as latent heat until the latent heat is up to the maximum. The temperature is kept at melting point for a period and the temperature increase is delayed. Therefore, PCM systems are also called as conductor and buffer systems.