A few years ago the first prototypes of 3D printers were made to work with plastic filaments, making possible practical and innovative designs for that time, although they had some faults and little acceptance by the average consumer, the companies went ahead with the innovations and now we can even find pencils that work with the same dynamics as a printer with some features below of course, but in short it is like a portable 3D printer. But what if we change the plastic and imagine a 3D printer but a metal one?

Join me in discovering this technological advance that is shaking the metal manufacturing industry.

Desktop Metal

This company located in Massachusetts, is dedicated for years to manufacture equipment related to 3D printing on metal, a little over a year ago presented to the world two of its large 3D metal printers: Studio System and Production System. It is based on additive manufacturing with metal is a little more economical than other printers and can produce faster, counting the technological advances in the area of non-pollution.

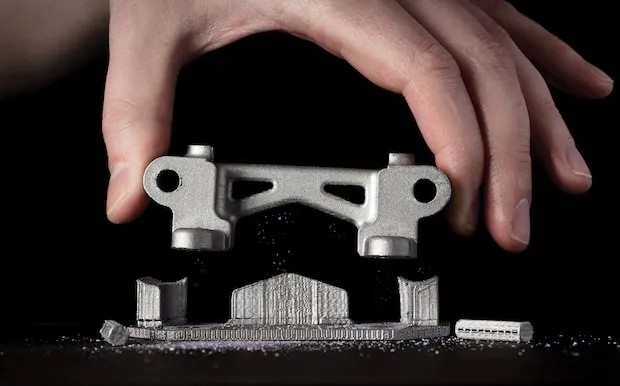

Studio System

Office or desktop-size 3D metal Impreora, which works with its patented Bound Metal Deposition (BMD) extrusion system. Very similar to their cousins, the 3D plastic printers, these printers have metallic powders that are unified with a special mixture of polymers, after printing, the pieces go to a furnace that melts them at a temperature of 1400 degrees Celsius, melting the polymer leaving a piece ready and clean, unlike metallurgy which is counterproductive to humans and many cases toxic, these printers are environmentally friendly as they do not require even an extra ventilation system, the Studio System, along with the furnace and program available in the cloud, costs about 120,000 USD.

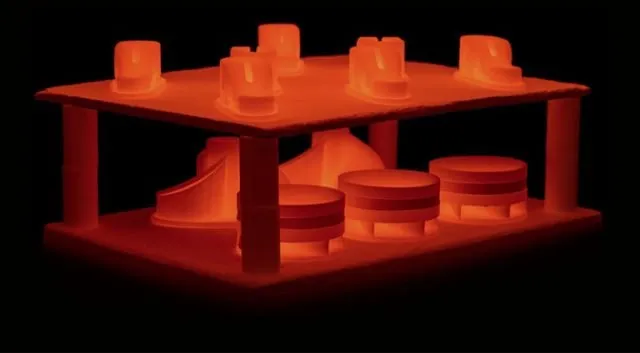

Industrial Size

There are other printers that belong to a process called "Single Pass Jetting". In contrast to the previous printer this works depositing the dust and then add chemicals to join the elements, have at least 35,000 jets that spray millions of drops per second to make parts of greater volume in less time, after printing, an oven is used to finish the smelting. This complete system is around 360,000 dollars.

Although they seem expensive to you they are actually very economical compared to traditional metal manufacturing systems, about a million dollars, it is expected that over time the price will become cheaper, many investors are encouraging this initiative as is the case of General Electric, BMW and Alphabet who have contributed one hundred million dollars for the impulse of Desktop Metal. Due to the high competitiveness that means the traditional market is the company is going a little uphill, although its goal is very outlined, reinventing the parts manufacturing industry will not be easy.

Its commercial phase is the most awaited and still not ready and is where they are working to reach more strata of the population and massify this incredible technology. If successful it will help a lot to the emergence of new initiatives which will undoubtedly bring evolution in the not too distant future displacing the old and polluting technology. They have barely 3 decades, they have a long way to go.

At the moment there are many expectations and much enthusiasm on the part of the fans to the printers 3D, their cousins that work with plastic have not been given an industrial utility so this is greater challenge for the Desktop Metal, we hope that everything goes for goo.

Thank you for reading

If you liked reading this article, feel free to FOLLOW ME, UPVOTE and RESTEEM! It's always appreciated =D. Thank you all for your support and see you soon for the news flamingirl's adventures!