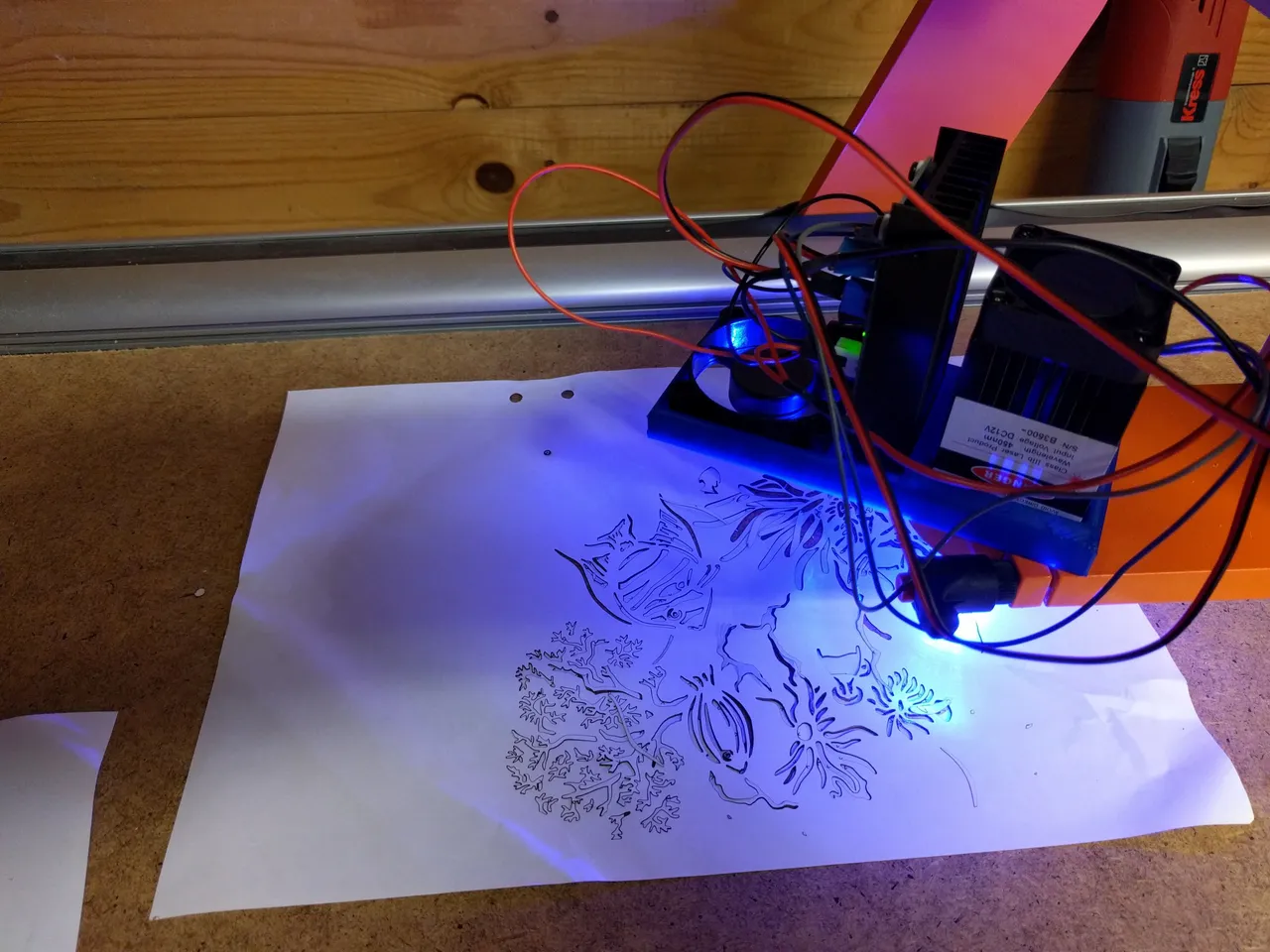

I needed to test the precision of my new laser...

So I took a .jpg file and converted it into a .svg file in Inkscape by using the "tracing bitmap"-function. I imported that into Autodesk Fusion 360 CAD program and extruded it in the model environment. I switched to the CAM environment and made a G-code file for the CNC machine to read, turned out to be more than 100 000 lines of direction changes!!

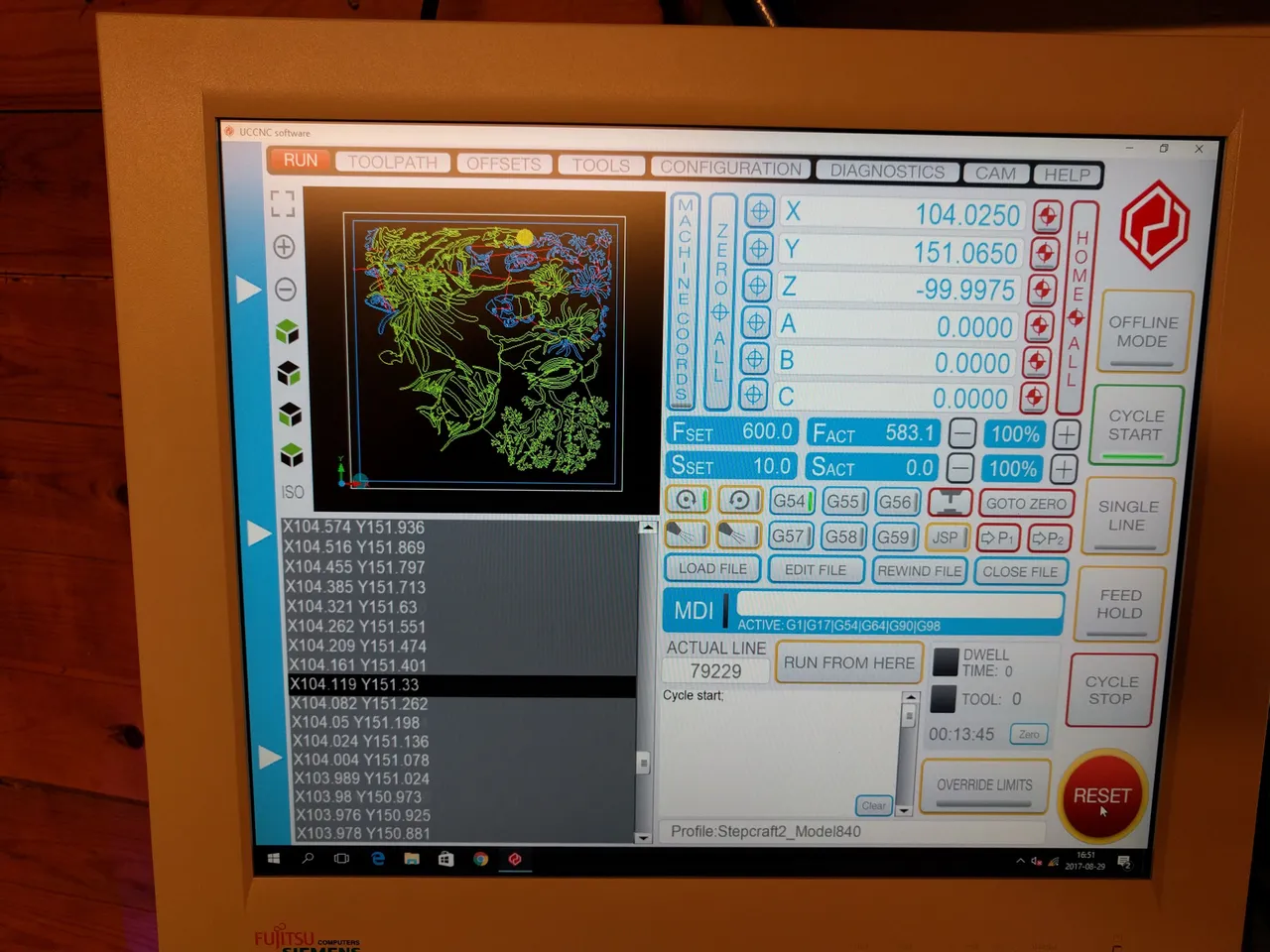

Here it is at line 79229 and it still has some way to go... I run the 3.5W laser at 50% power and 600mm/s, cuts paper easily at that setting!

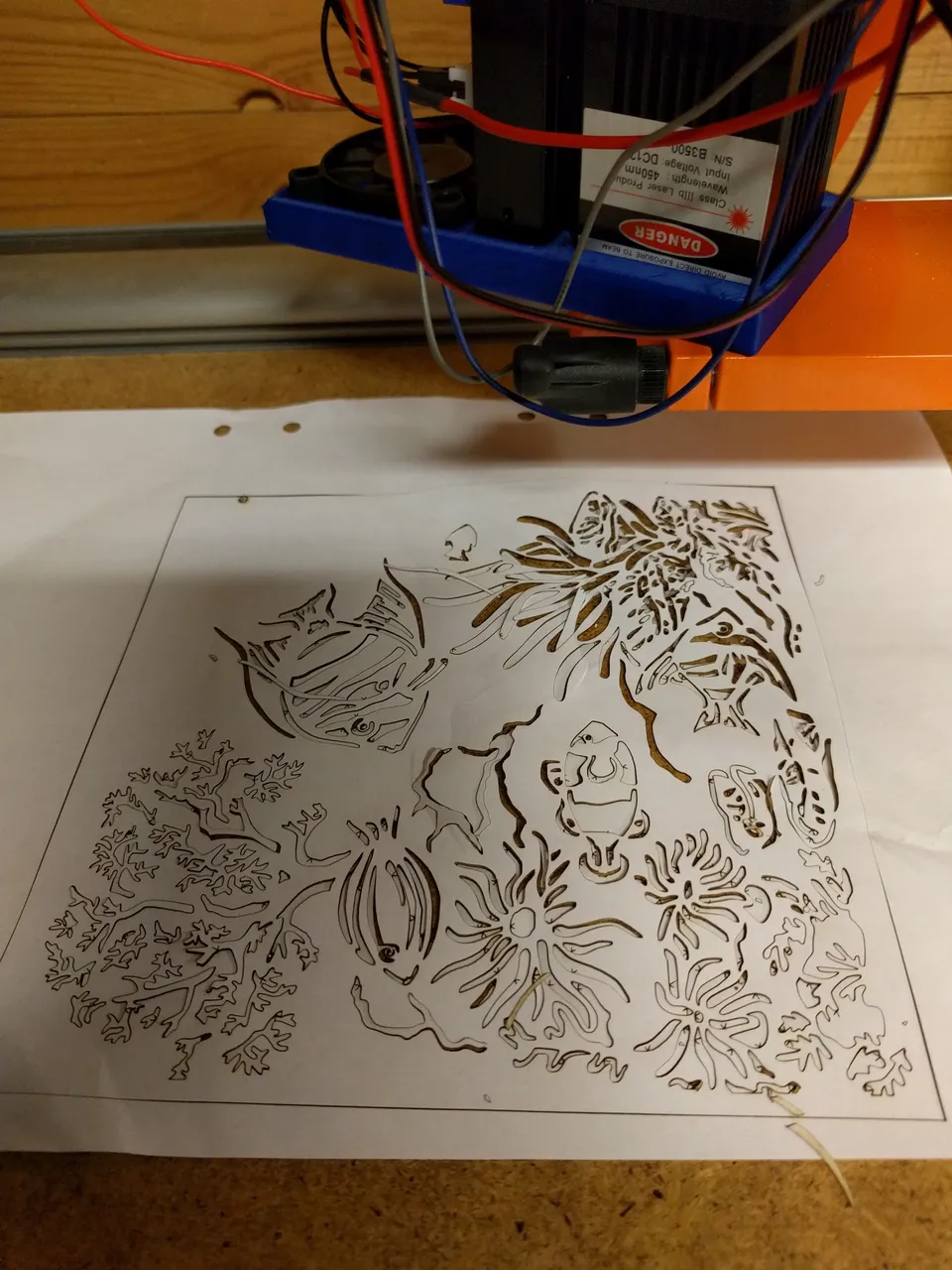

After 22 minutes the laser was ready and here is the result:

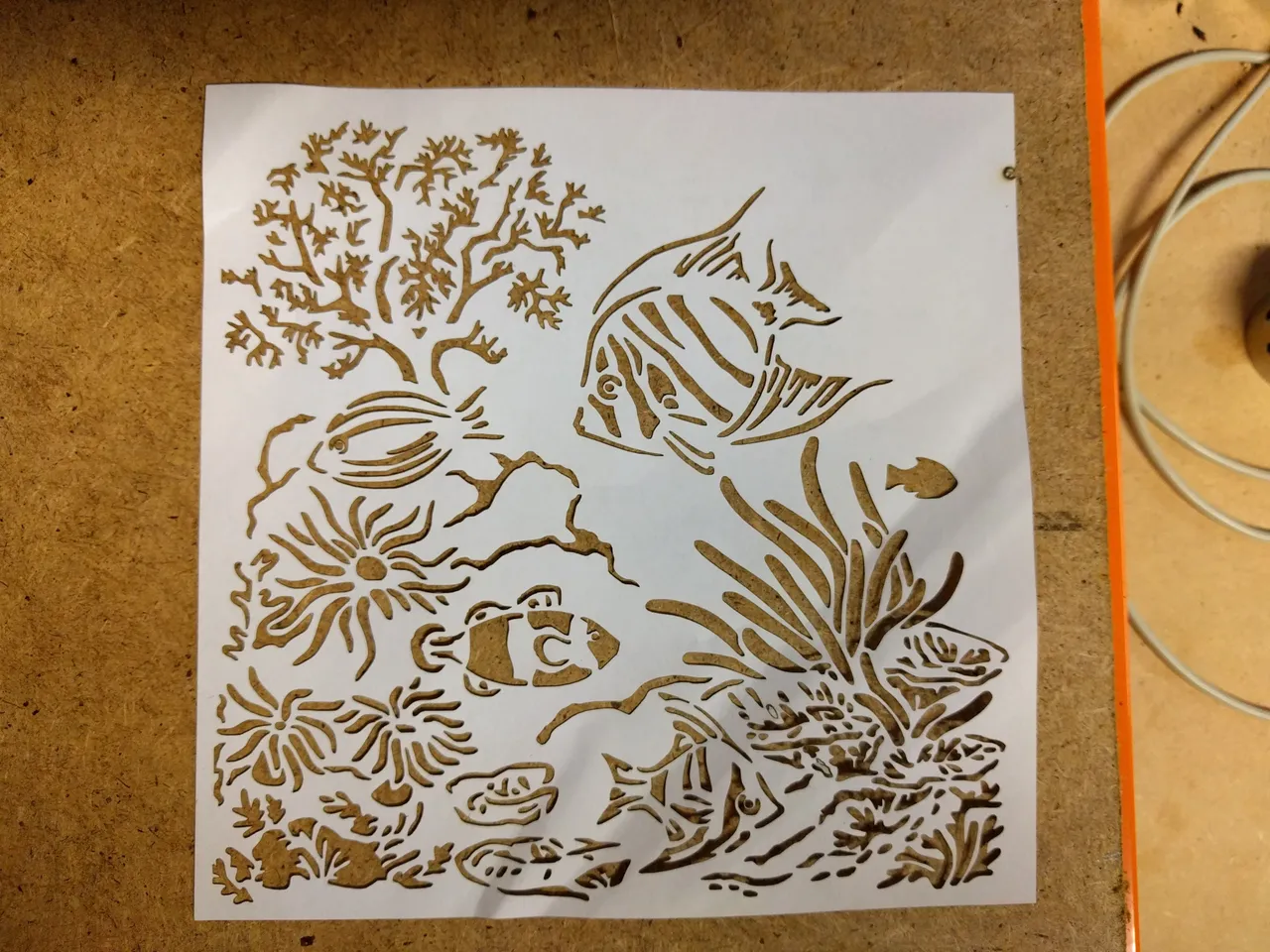

Another picture with the loose paper pieces removed:

It turned out way better than I had expected, success!! Just one flaw in the upper right hand corner, I must remember to send a M11 G-code before turning the power to the laser on, otherwise it will start lasing as soon as it gets power...