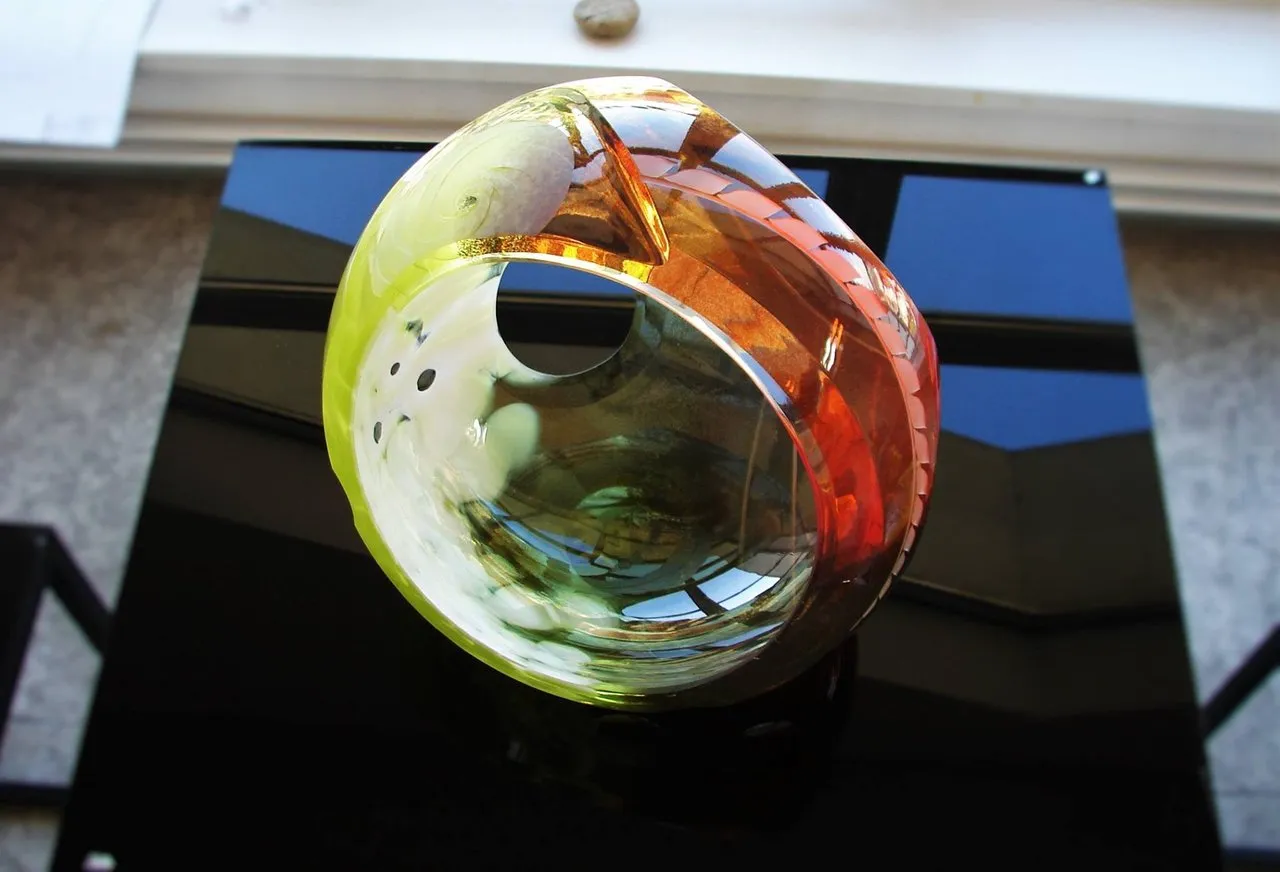

Hello steemit friends, I would like to share with you another of my glass works. This time extraordinary bowls.

This is my graduate work from 2016.

TOPIC: In the dance twirl

TIME: 2 months

REALISATION: idea, sketches, technical drawings, written part, products

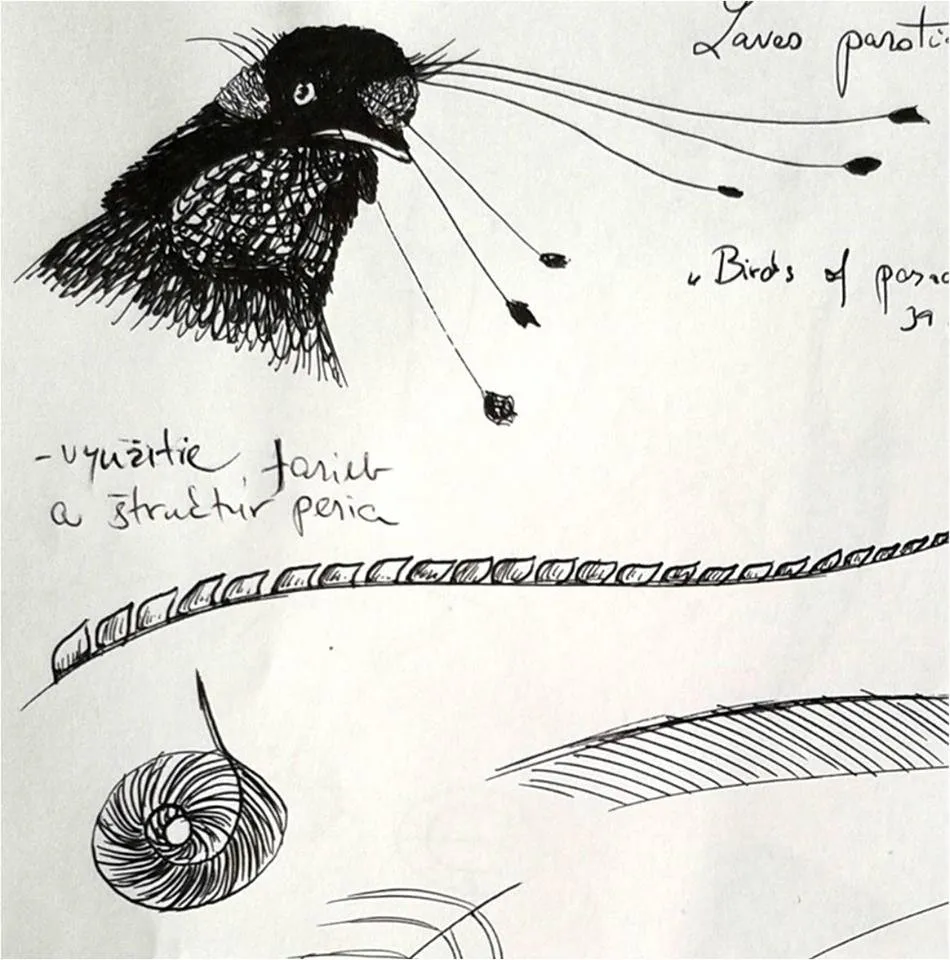

The purpose of this work was to examine the nonverbal communication of dance among the history of human kind and nature. We can talk about dance in many different meanings. It is a way of relaxation, expression, communication, and much more. My main interest was animal kingdom, especially Birds of paradise from Papua New Guinea. Every species of the family Paradisaeidae has something special. Some of them has uncommon voices, or beautiful unnatural feathers, but we focused on their behavior, mainly their dance.

The birds of paradise were my inspiration to create three glass objects - unusual round bowls. I tried to display a life of this special animals in colors, shapes and decorations.

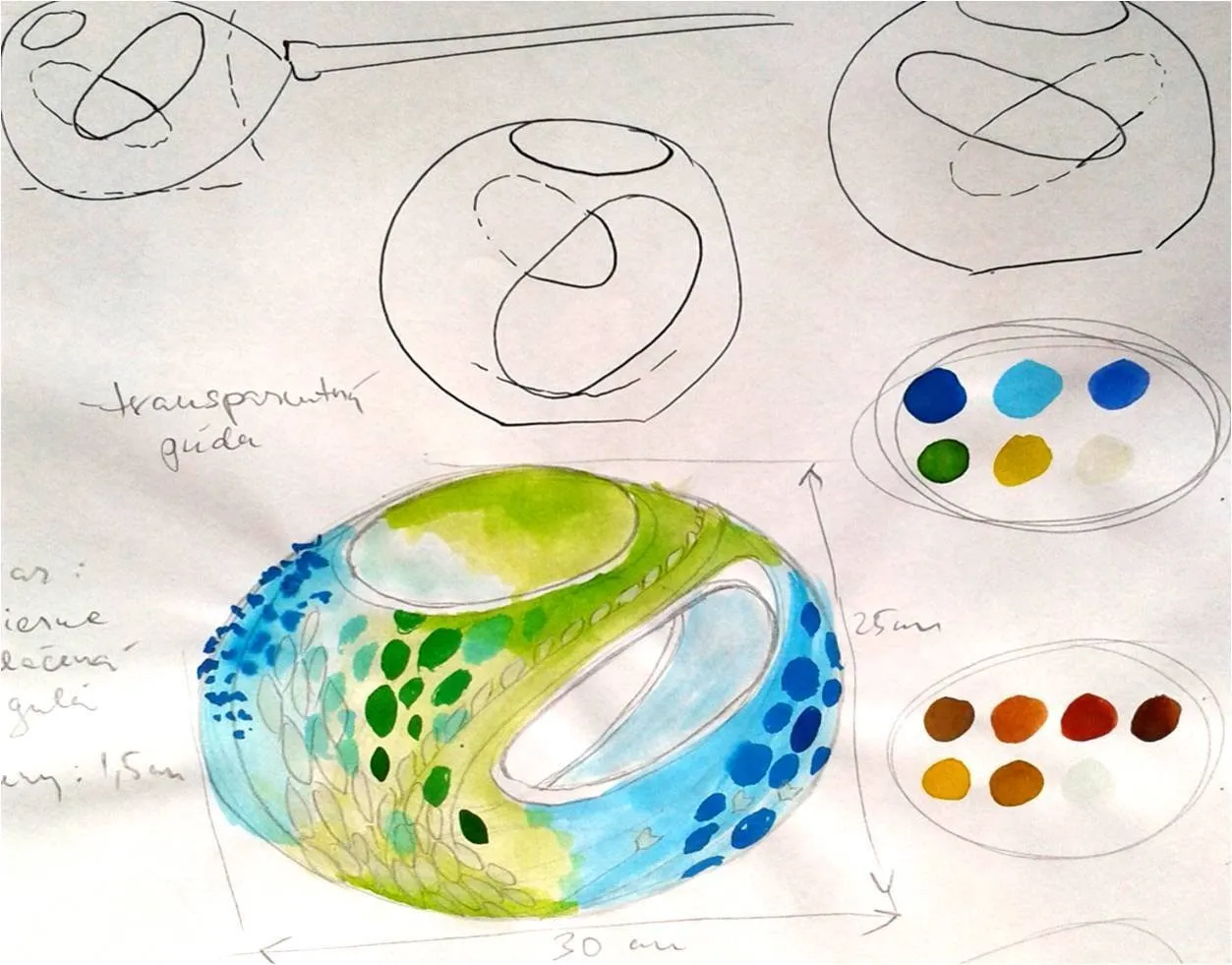

1. SKETCHES

When I got the idea of Birds of paradise I had to put it into a glass objects. It is not easy to blow a bird, so I decided to choose an egg.

I tried to find the right color combinations according to a birds feathers.

There were some nice combinations. I have chosen ble, green and red and white color.

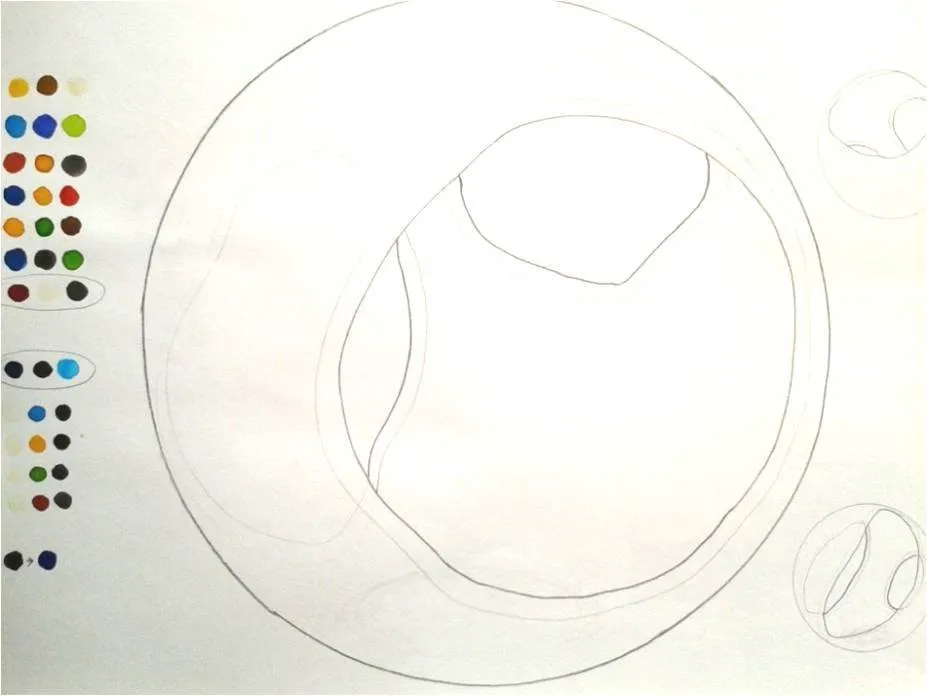

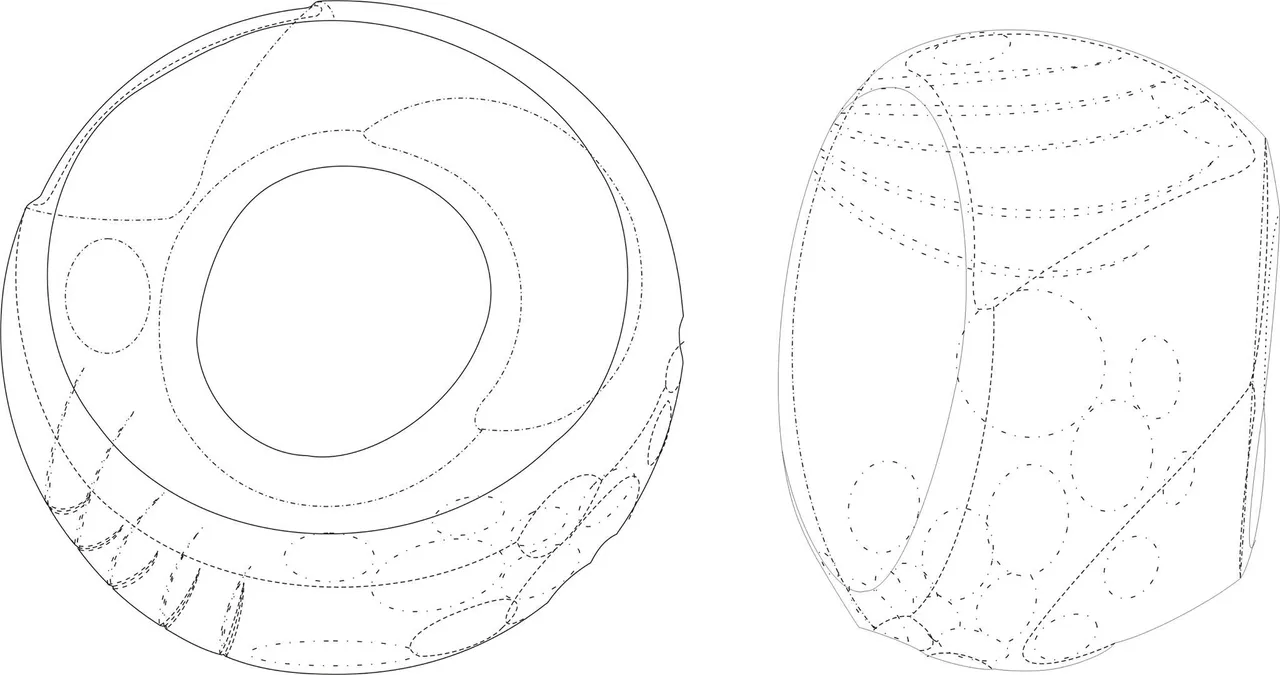

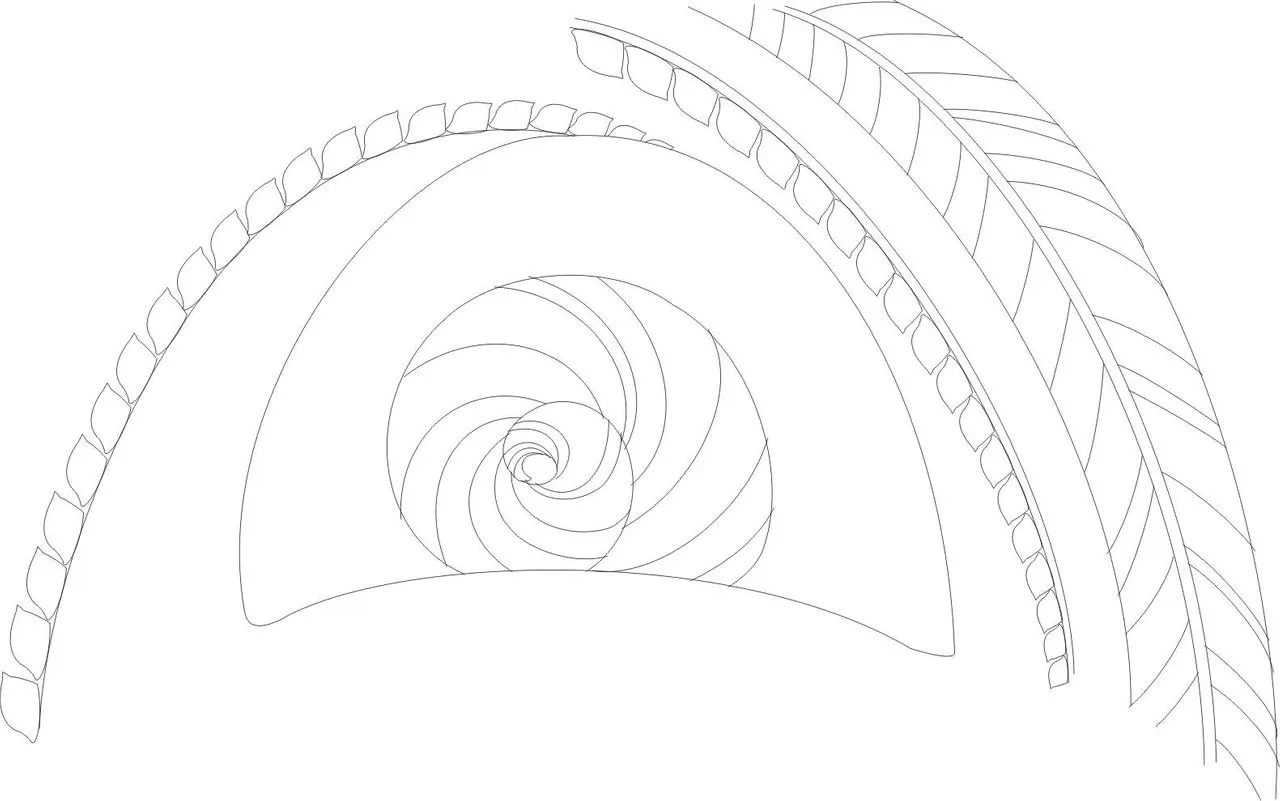

2. TECHNICAL DRAWINGS

After I finished my sketches and I knew what I am going to create I had to draw the exact objects.

It was the most difficult part.

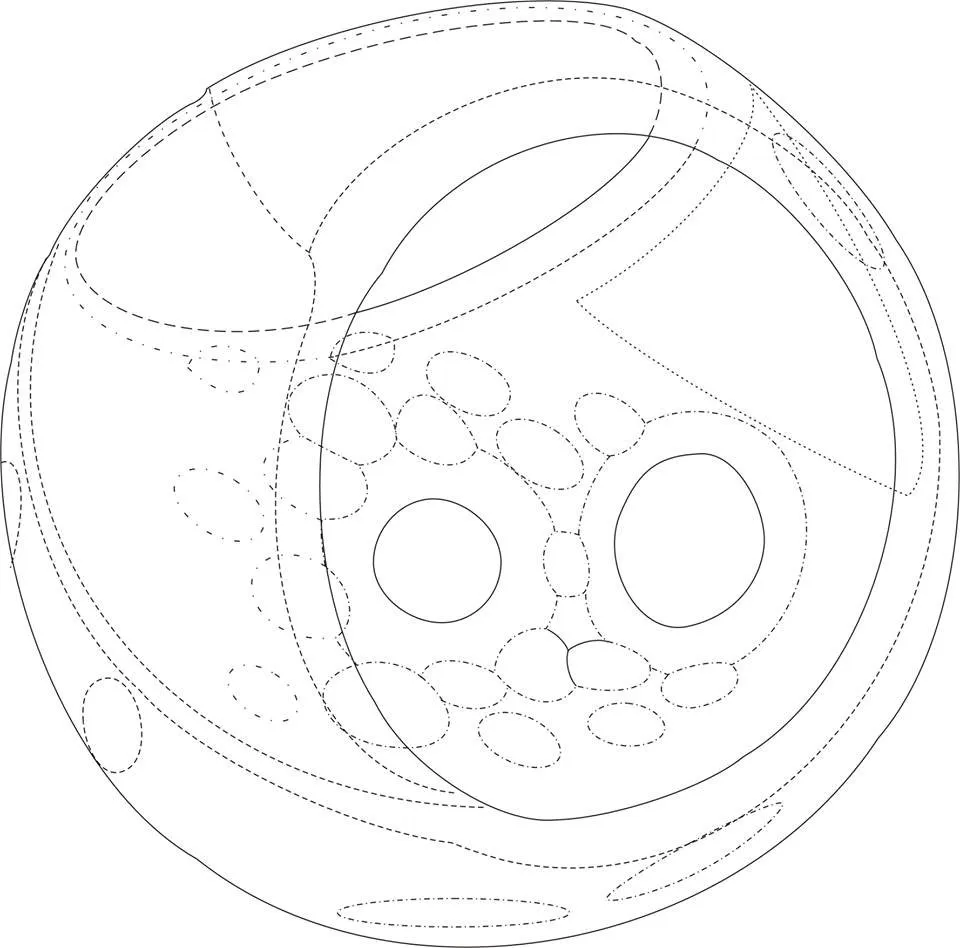

I also wanted to decorate the objects. The inspiration came from the unusual shaped feathers of this birds.

The drawing was cut into a wallpaper as a pattern for sandcasting.

3. BLOWING GLASS

A temperature around in a kiln is about 1200 °C, so you don´t want to be arond very much. First you have to blow a small bubble and enwrap it into another amount of glass.

The glass is like honey, but it cools off quickly. When you want it to be round, you have to roll it in a wooden mold.

There are colorful sands and powders made of glass to dye.

Because of the size of the objects and my poor skills in glass-blowing this part had to be done by my master.

After the glass is blown it has to be put into tempering furnance, so the glass can not crack while cutting.

4. CUTTING AND GRINDING

I made the holes on a diamond disc. It was really slow and hard work, because I had to hold and push the glass against the disc for hours.

I am smiling just because this piece was the last one. The previous two were done. The whole cutting and grinding work took me about 45 hours and I could feel it on my hands the next two weeks :D

5. SANDCASTING

Nice and quite easy part of this work. The only problems were while sticking the template on a glass because of its round shape. Those dark places were sandcasted, so they turn white and rough after washing.

The results

The price of them together is 113,42€ (material only). The work without mental process took about 60 hours.

Thanks for watching!

Follow me on Steemit