Hi guys, it feels good to have you here once again and I sincerely do appreciate your time, comments and upvotes on my past articles. That being said, I'll like to continue from where I stop on my previous article which was centered on how to save cost when it comes to going solar. Solar PV modules (another component in solar power system equipped with the capability of convert light energy from the sun into electricity) comes in different types, ranging from the commonly known crystalline silicon type and thin film types. Certain choices as regarding quality, performance and price are some of the challenges we must faced when choosing the appropriate photovoltaic modules. The crystalline silicon type are by far the most commonly used solar module around the world especially here in Nigeria because of its enhanced performance over thin film type. It can be grouped into two main types namely; monocrystalline and polycrystalline.

Although both types can be a good choice for your household serving the same purpose, there are quite a number of key differences between the two technologies one must put into consideration before buying. Truth be told, monocrystalline module are more efficient than polycrystalline module. So to say, monocrystalline are better, but when you put their cost effect into comparison, polycrystalline are cheaper. Now to real questions that I think we needs to address. Does the extra cost actually justifies the extra efficiency? How come monocrystalline modules are more efficient and expensive compared to poly counterpart since they are both made from silicon crystal? Would you really say the mono-type is better than the poly-type? So in this article, I'll take my time to address this questions as this will help in your decision or choice of module to go for when going solar.

But before I proceed to do justice to all these questions, firstly, I'll do a little introduction on how silicon is used in produce solar cell that generates electricity, as this will help us to understand how the efficiency of monocrystalline panel come to be. Mind you, arrays of solar cells make up a solar module. I am sure that we all still remember our first twenty chemical elements from our college days right! For those who don't, silicon is among the first twenty element with the atomic number 14 and the symbol Si. It is a semiconductor with a bluish gray color that comes in a hard and brittle crystalline solid whose impact on modern world economy can not be over-emphasis as it found its usefulness in numerous fields like steel refining, aluminium casting, integrated circuit and many more.

It has also found its usefulness in the production of solar cell being the primary material needed. For solar module production, silicon is required in its purest form which is of course not pure in its natural state (crushed quartz or quartzite gravel).

To purify this element in its natural form, it is placed in an electric arc furnace and is heated at a temperature of 2,500°F to produce molten silicon which is later allowed cool down to form what is known as an ingot. Even with effort of trying to make it pure, it still retain 1% of impurity in it which is then further refined in a floating zone process.

These ingots are then chop into square wafer, the shape of convectional solar panel cell in market nowadays.

However, in their purest form, these semiconductors are actually a poor conductor of electricity. So in order modify their electrical property, they are doped or treated with elements like phosphorus or boron which increases the number of charge carriers within the silicon wafer. The half made solar cells are then completed placing electrical contacts with thin strips of copper to link the solar cells together and receive the current generated. Also an anti-reflective coating are placed on the silicon wafer to reduce the amount of sunlight reflected due to the shinny lustre of the silicon. And final, the Solar cells are then sealed with either silicon rubber or ethylene vinyl acetate and then placed into an aluminum frame that has a glass cover with a Tedlar back sheet. For a more detailed explanation on how solar cells are produced, you can go through this article.

Now, enough of introduction, let us discuss a little about the manufacturing process of each crystalline cells, their pros, cons and their performance differences.

Monocrystalline module

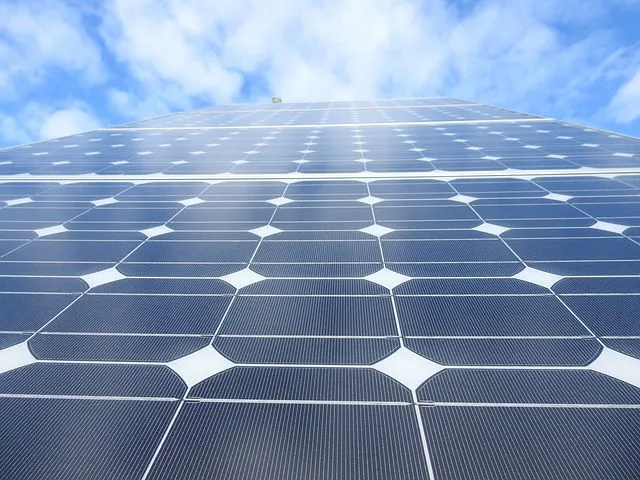

Being the first of its kind in the world of photovoltaic module and also the most developed system, monocrystalline solar cell, from its name "mono" is manufactured from one single crystal of pure silicon using Czochralski method. This involves dipping and gradually pulling of seed crystal in and out of a molten monocrystalline silicon to form what is known as an ingot. The ingot being pulled up by the rotating seed crystal, has its temperature lowered to form a conical/cylindrical shape on cooling. This manufacturing process gives the monocrystalline cell it's uniform dark blue or consistent black color which solely indicates that level of its purity and how electron flows with its field. If we are to take a closer look at each individual cell in a monocrystalline panel, it has an octagonal shape with four lines on the edge round-like. The round-like edge was gotten as a result of trying to manage the amount of materials wasted when cutting the silicon ingot into the required square cell.

Pros

• They are known to possess highest degree of efficiency at 16-20% with a solid warranty of over 25 years.

• They tends perform better in hazy weather condition and requires less space for mounting compared to poly due to its high efficiency.

Cons

They can be more costly than all other types of PV module owning to its manufacturing process and the numerous amount of silicon wasted during the manufacturing process.

Polycrystalline Module

Polycrystalline cell also known to be multi-crystalline, can be manufactured when several fragments of silicon crystal are melted together by placing them in a furnace. What differentiates the production of poly panels is that instead of lowering the rotating seed crystal into the molten silicon as the case of mono, it employs a more quicker and cheaper manufacturing process that involves the pouring the melted silicon into a square mould which is allowed to cool down and then cut into the desired square wafer. If we are to take a closer look at each cells in a poly module, you'll see a bluish frost-like colour that indicates the presence several fragments of silicon chips melted together. This effects restricts the freedom of electron flowing within the cell and in short, the main reason why poly panel are less efficient compared to its mono counterpart.

Pros

It's manufacturing cost is way less expensive with a faster manufacturing process compared to mono.

Cons

• They are roughly 3% less efficient compared it's mono counterpart

• Decrease in it's efficiency lower their output power which cause them to take more space when installing them.

If we are to compare the differences between these two technologies a decade ago, it was obvious and certain that the mono-type are way much better, with just a glance at their specs. But lately, advancement in technology has practically made both crystalline type interchangeable. To simply put, improvement in the manufacturing process of the poly-type has greatly improve it's efficiency far better than what it was in the past. So I can actually tell you that polycrystalline modules are also better than its mono counterpart in some area.

To back up my statement, let us consider some of the perfomance differences of both crystalline technology. Am sure you should be now, know some of the features possess by the individual technology that makes them different from one another.

Efficiency

Efficiency! A key performance that differentiate both modules from one another. But what do I mean by the term "efficiency" when it comes to solar module? This is the measure or rate at which a Solar module is able to maximize the energy from the sun to produce electricity in a particular area and at a particular time. For instance, when you place two solar modules, one mono and the other poly of the same size in the same location, the mono tends produce more power than its counterpart because of their manufacturing process and the purity level of the silicon used. This effect makes the module with highest output power more efficient. And also mono cells tends to work better during cloudy or hazy weather than poly cells.

A lot of people and consumer are always concerned with efficiency of a solar panel when accessing their quality before purchasing which is a good thing. But I am tell you today if you are among such people "efficiency I say is not as significant as it was in the past". If we are take their cost into consideration, you will realize that the extra efficiency that is gotten from mono panels, you are actually paying for it if not paying more. Does this still sound a bit confusing, let's do a little calculation here with two solar panels one mono, the other poly of the same size, made from the same manufacturer, taking Solarworld product for instant. If you are to install ten 270W mono panel at the rate of #40,000 each.

Total money spent on the twenty mono-panels;

10 x #40,000 = #400,000.

Total power output of mono-panels;

10 x 270W = 2,700W

To obtain the same total power output with a poly panel of the same size with a power output of 260W sold at #36,000, you'll be need eleven panel to obtain closed to the desired total power output, making the cost of acquiring them to be;

11 x #36,000 = #396,000

Total power output for poly panels;

11 x 260W = 2,860W

Now let's observe the little math we did just now, efficiency seems not to matter as we were be able payless (#4,000) and gain more power (160W) from the system while making use of poly panels even though mono panels are more efficient.

Does the extra cost actually justifies the extra efficiency? For my on point of view, I'll say NO. Do you know why? Taking their extra efficient and cost into account, you'll realize that mono panel is 3.85% more efficient while poly panel is 8.1% less expensive which indicates that I am actually paying more for the extra efficiency.

Although, part of the extra #4,000 can at times be spent on extra rail and labour for mounting the extra panel.

Another fact again concerning efficiency is that even though mono panels tends to work better in hazy or cloudy weather, but with the help of equipment like charge controller, DC optimizer, micro-inverter etc, poly panels tends to work better as well.

Temperature coefficient

Another performance difference is how both crystalline module reacts with temperature. Standard test operations carried out on solar module has shown that they perform less efficient under high temperature. Interested in learn more about the impact of temperature on solar check out this article. Even with this, some of these modules seems to handle this temperature better than other. Take mono panels for instance, of all the different types of modules produced around the world today, they seem to handle the heat better, an additional advantage which has lately being less significant especially when compared with poly panels. Comparing the temperature coefficient of the two technologies shows that monocrystalline Short Circuit Current (SCC) drops by 0.04% Amps for every degree Kelvin over standard test condition of 25°C or 77°F while polycrystalline SCC drops by 0.051% Amps. That is to say, for every increase in temperature, the output current of the panel decreases, same with its power output.

Does their different really matter, let's do a little math to obtain the current drop difference when the temperature is 20°C hotter.

For mono-panels

0.04% x 20 = 0.8%

Current drop = 0.8% of SCC

= 0.8% x 9.44A

= 0.076A

For poly-panels

0.051% x 20 = 1.02%

Current drop = 1.02% of SCC

= 1.02% x 8.94A

= 0.091A

Temperature drop difference

= 0.091A - 0.076A

= 0.015A

Taking a look at the result we got above, you will discover that the difference does not matter. Maybe for extreme desert condition, the difference may be big enough to matter but most residential environment, the difference is to small.

So, which one is better then?

That is up to you and the needs of your project specifications. If you are on tight budget with the intention of keep the cost of installation as minimum as possible, provided you have enough space for panel mounting, your answer is polycrystalline modules. But if efficiency is what you desire, you can go for monocrystalline modules which requires less space for mounting. A typical example is shown in the images below

Polycrystalline modules on the ground mount; Image source: me

Monocrystalline modules mounted on the roof; Image source: me

Aerial view of the entire system; Image source: me

The modules mounted on the ground are poly-type while the ones mounted on the roof are mono-type. Why? Because of the reasons I stated above and also their temperature differences. The poly-type on the ground mount has enough air circulating underneath the panel rails to cool down it's temperature compared to the mono-type that is mounted directly on the roof. I guess that balances out their temperature differences.

And on a final note, I hope you have being able to understand that when it comes to choosing a photovoltaic module for your solar power system, it's not all about efficiency or temperature coefficient but what you desire for your system and how best you can spend less for quality power system while making your environment safe as well. Till next time, keep steemit.

References

• Difference between polycrystalline and monocrystalline module