Invitation for Steembid No. 1

Requirement : Proof of Work ; Cad & Physical model in a blog documenting the request below of a functional oven which can bake a Tortilla.

Criteria : This will be Steemsource ( no patents )

I plan to reward based on functionality and aesthetics; but the steemit community will decide by an open vote anyway , your try will be worth it ;)

I am calling once again for everyone to test a knowledge based basic income experiment with the aim of solving a project I have been thinking for some time now.

I currently don't have access to 3D modelling and 3D printing, but believe here are the people who can just get this done in a day. I look forward to expand the discussion and clear our doubts in the comments below.

I will give away 100 Steem (could be worth anything tomorrow) form my wallet to any one or a team who ultimately brings about the proposed solution to reality.

Please feel free to propose alternative better solution.

Short Introduction to the problem

People all over the world use wood fired Flat clay griddles for baking Tortilla, Crepes and Pizza. Often times in open fires like below which not only are inefficient but also heavily polluting; with harmful heath effects mainly to the women involved in bringing food to the table.

Replacing the Solid Griddles or Comaland the Oven enclosures with a better design will bring about less pollution, more fuel savings and overall sustainability.

All Images are from the Internet and used here for illustration purposes only

The Solution:

1. The Griddle

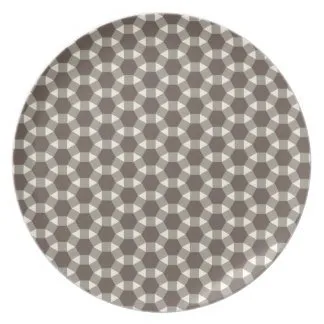

Clay based Tessellated Hexagonal Terracotta Tles seamlessly held together by a compressive band of Steel. Desired thickness of griddle assembly 1 cm, Diameter 45/60 cm. Additionally an interlocking blocks design that would support the griddle and enclose the fire.

2. Enclosure body

Refractory based ** Interlocking Hexagonal Terracotta brick lego seamlessly held together by a compressive band of Steel**. This blocks would support the griddle and enclose the fire. Desired thickness of wall assembly less than 10 cm, external diameter 45/60 cm, height 20 cm. Should have an opening for smoke out let.

a) Basic : cylindrical body profile

b) Advanced ( for +100 Steem) : Spiral Golden ratio enclosure profile.

Note : In the construction method currently employed ( the last two pictures), the thickness of the clay cross section can not be practically lowered below 2 centimeters. This has a significant effect on the heat transfer/loss.

My ultimate goal is to reach to a Constructal Design, to be able to use a computer fan connected to a thermometric generator so a spiral oven can be used indoors.

The Imagined Building Unit may be 8 cm across?

Once arranged in such an order ( But in a circle of 45-60 cm)

The Lego like units will be held by a compressive band of steel and are bolted (welded).

More on the idea here

Such 1 kW heaters should be able to power the over eventually.

The hard work of working clay

Drying in the sun

If you think this is a good idea or you support the ideals behind this idea then please vote it up. Every Steem generated will be used to refine the concept and include your say. Your support may bring innovative solution to the millions of people who need it badly & will be remembered permanently by the Blockchain.

References & inspiration

https://www.littleboxchallenge.com

http://www.data-clay.org

https://constructal.org

https://www.slideshare.net/mobile/cuong260388/belonio-gasifier

#steem #steemit #steemjob #bid #howto #hardware #reward #betheone #diy