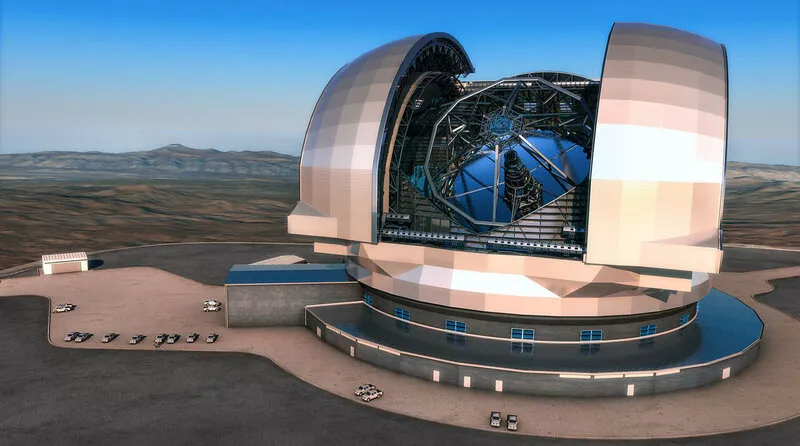

Extra LargeTelescope (ELT), the largest telescope in the world, is now under construction on top of Cerro Amazones in the Atacama desert of Chile, at the attitude of 3042 meters above sea level. When completed, it would provide images, 16 times sharper than those from Hubble. The 39-metre-diameter primary mirror, which will be made up of 798 individual hexagonal segments each measuring 1.4 metres across, will be by far the largest ever made for an optical telescope. Together, the segments will collect 100 millions of times as much light as the human eye.

Image: ESO/L. Calçada

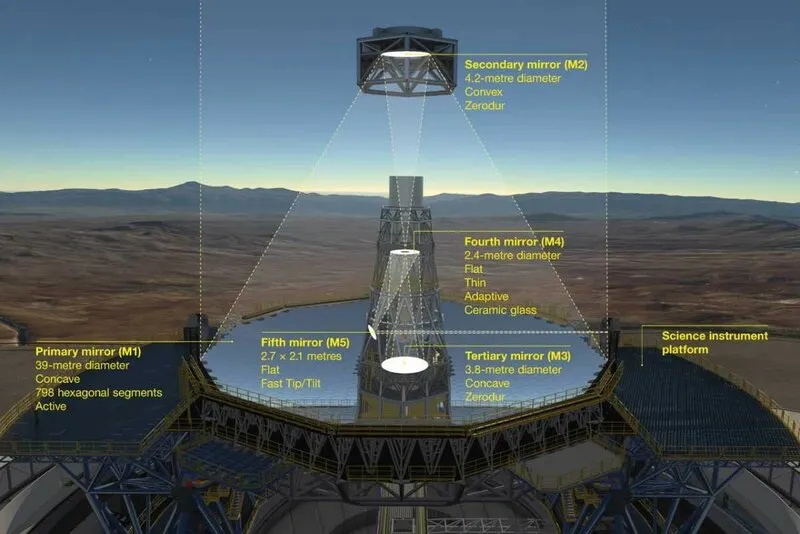

Contract for manufacturing segments of the primary mirror ESO awarded to German Shott - subsidiary of Carl Zeiss Stiftung. 1.4 meter sized hexagonal segments will be produced from the low expansion ceramic glass Zerodur. Previously SCHOTT was also awarded the contracts for the production of the telescope's giant secondary and tertiary mirrors and the material is also being used for the ELT's deformable quaternary mirror that is currently under construction.

Image: ESO - ELT optical scheme

The compound primary mirror will be adaptive - positon of each segment can be changed to correct atmospheric distortions. Four lasers will control atmospheric conditions and give command to change segment's positions

Image: ESO - Adaptive optic, controlled by lasers

Once the mirror blanks are ready they will be passed to the second contractor - Safran Reosc, to design the mounting interfaces, figure and polish the segments, integrate them into their support systems, and perform optical tests before delivery. During the polishing process, each segment will be polished until it has no surface irregularity greater than about 10 nanometres—no higher than a ladybird if each segment were as big as France!

Safran Reosc will also design, polish and test the ELT's secondary mirror, which was manufactured also by Schott in May 2017, and tertiary mirror, and is currently manufacturing the 2-mm thick deformable shell mirrors that will comprise the ELT's fourth mirror

Image: Schott/ESO - Opening of the ELT M2 ZERODUR® blank mould containing the still very hot ZERODUR® glass at first annealing at the SCHOTT 4-metre blank annealing facility in Mainz, Germany in May 2017. The completed mirror will be 4.2 metres in diameter and weigh 3.5 tonnes

Both SCHOTT and Safran Reosc have long and successful involvements with ESO. Together they manufactured many optical components, including the 8.2-metre main mirrors of the four Unit Telescopes of the ESO Very Large Telescope - the largest telescope for now. Among top 10 astronomical discoveries of th VLT the first direct inage of the exoplanet and first measurements of exoplanet's atmosphere.

VLT discoveries are so amazing that it's difficult to imagine what we'll see after ELT will see its first star light in 2024.