Source: pxfuel.com

A world without plastic today is hard to imagine, simply because it represents the easiest and most economical way to package consumer goods, not to mention the many industrial applications they have, from automotive parts to medical instruments. But we all know that reusing and recycling conventional plastics is an uncommon and even expensive practice, so the idea that has been on researchers' minds for some time is the development of a plastic with the property of degrading very quickly, not in the 100 or 200 years that a conventional plastic bottle can take.

This is a plastic product derived from the fermentation of waste, which could mean a positive impact with respect to the use of disposable products. It was developed by the Fraunhofer Institute for Production Systems and Design Technology IPK and its associates. This group of researchers has sought to develop a method for obtaining polymers without the need to resort to raw materials that are indispensable in other areas, such as vegetable oils or synthetic petroleum derivatives.

A new plastic

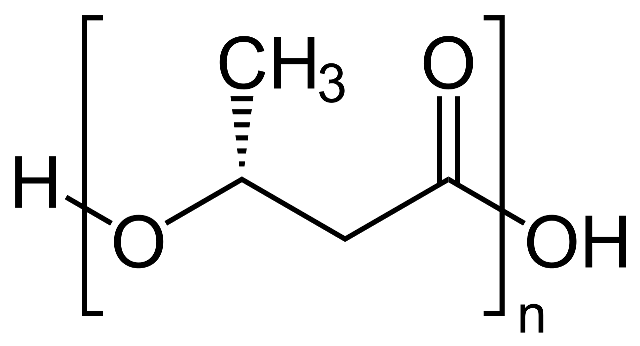

Through a new synthesis process, microorganisms such as Bacillus megaterium are used, capable of degrading industrial waste as waste fats when they have no other sources of energy available; thus, scientists have used bacterial fermentation to metabolize industrial fats and obtain the polyhydroxybutyrate macromolecule. Microorganisms deposit PHB in their cells to store energy, but even at this stage it is not ready to be used, the hardening process takes some time and it must be mixed with other additives in the following stages of the process. But by adjusting the time of plastification and other variables, scientists have obtained a plastic with characteristics similar to polypropylene, with the difference that the bioplastic can be degraded from 6 to 12 months.

Structure of poly-R-3-hydroxybutyrate. Sourece: wikipedia.com.

Through this method, the plastic is completely synthesized by microorganisms in a biotechnological process, in which residues such as fats are converted into more usable polyesters. The team of scientists uses genetically modified microorganisms that serve as biocatalysts, and with the following stages of chemical purification, they achieved a new material that meets the technical demands of plastics.

Biodegradable

The new material not only dispenses with the need to use petroleum-based synthetics as a raw material, but also provides a biodegradable plastic alternative.

Source: Wikimedia Commons.

Microorganisms naturally present in the environment can metabolize these materials and degrade this family of plastics without the need for special operations in industrial composting plants or landfills, and they can be manufactured and recycled in a more environmentally friendly way.

In short, this procedure seems to be a more environmentally friendly alternative to conventional plastics and other families of bioplastics that have already been shown to incorporate hazardous chemicals into their composition. However, in order to see its widespread use, it is necessary to demonstrate that its implementation can be economically feasible, since, like many other green technologies, this type of procedure is more expensive than conventional methods and does not provide materials with more specific characteristics for the manufacture of parts for certain technical applications or that can be reproduced with great precision. But hopefully in the near future these drawbacks will be solved because we need to minimize the plastic footprint we are leaving on the planet.

Thank you for reading me. Until the next post!