Nothing like a bright warm fire when it’s cold outside

We have heated with wood since 1978. Since 1983 we have used wood as backup to our passive solar heating. My husband was born and raised in Florida and he says if he has to work outside in the cold, he’s going to be WARM inside. So our house is between 75 – 85F year round. And nothing makes you warmer than wood heat.

Now that we have started burning the stove for several days, I thought a post on wood heat was appropriate. This is really early in the season this year to start, it isn’t even the equinox yet!

We light the stoves at dusk, after pulling all the heavy duty window shades to keep the heat in. That is, unless it’s been a cold dreary day, and we might have them going all day.

The History of Our Stoves

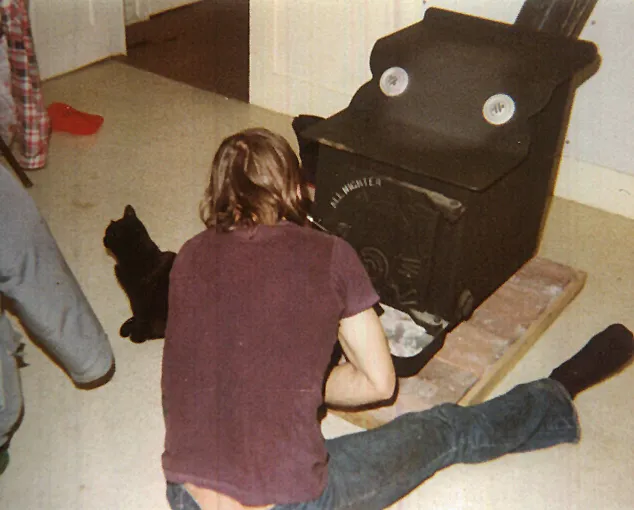

We rented a house in 1978 and were allowed to have our first woodstove. It was an All Nighter, bought new. The thing we remember most about this stove was that it NEVER burnt all night. Also it was too small for the house it was to heat.

Our first stove in our new passive solar heated house in 1983 was given to us. It was a Sevca. This house was small, just 16’ x 18’, 1½ stories, but heavily insulated for the time. This stove never burned very well. It burnt too cold due to the large upper chamber and there was always creosote buildup in the chimney.

It was replaced in 1986 by this Round Oak. This stove was lovely, but its steel sides did not last long. We sold it to the stove repair person who did the work, decades later, on our cow stove door. While we were at his shop delivering the door for repair, we wandered around looking at his refurbished Round Oaks.

It was replaced with this old Vermont Castings Resolute. This heated the little house just fine.

In 1990 we put the 20’ x 24’, 2 story, addition on, using many, but not all (I WAS going to have West and North windows!) principles for passive solar heating. We bought a new Vermont Castings Defiant Encore to heat this area.

We had to replace the catalytic on it every 2 - 3 years and they were expensive. Some of the moving parts for dampers also needed replacing. This stove never burned really well, probably because it needed an 8” flue and ours was 7”. It also used to creosote the chimney badly. But we used it until 2011 when it had too many broken pieces to warrant repair.

It was replaced in the stove buyout that Massachusetts was doing to replace inefficient woodstoves. We were able to afford a new Pacific Energy stove with this program.

It burns very well as it needs a 6” flue. Once we replaced the cheap firebricks with some quality ones, the maintenance on it is very low. The gasket on the door comes loose but that’s easily cemented back on.

With a good bed of coals, loaded at bedtime, it will burn all night and have plenty of coals in the morning to light with a couple logs tossed in.

In 2015, the Fuel Assistance program had a stove replacement buyout and we were able to get this plain version of the same Pacific Energy stove we had upstairs to replace the 30 year old Vermont Castings Resolute.

This stove burns too well, and as you can see we had to install a damper in the stove pipe to slow the draft. It tends to build up deep coals in the back that we must pull forward to burn down.

Our newest stove is a masonry heater in the addition. It’s not finished yet, we are still waiting for the stone for the façade. It will be an entirely new experience learning to use this.

It burns really hot, around 1500F, once a day, heating the entire mass. Then the fire is allowed to go out. It’s supposed to use half the wood of a wood stove, and you can use any type of wood, as long as it’s really dry. Because it burns so hot, there’s no danger of creosote. If it’s really cold, like below 0F, then you can burn it a second time, 12 hours later.

It should heat the entire addition. In the cellar below it, my husband will have his new rod shop. He will be putting a wood stove down there to heat that area. We’ve not decided what he will get for a wood stove for the shop.

Wood for the Stoves

When we were younger and healthier, we would collect wood wherever we could find it. We had a 1949 Ford F5 dump truck. It had a flathead 8 engine that went and my husband found a Chevy 307 engine for it. The Chevy engine's oil pan fit perfectly behind the front suspension/steering. Then he changed the bellhousing so it would line up with the Ford transmission. He loves Fords because parts interchange for years.

He hauled wood from all over this part of the state with this truck. After a few years of this, we were starting to be able to find wood close to us that we didn’t have to cut trees down to get. Someone offered us log length cords of wood for $5 cord and we moved many, many cords of this from less than a mile away.

We built a ramshackle woodshed out of split telephone poles (another thing we traveled all over collecting) and used sheet metal after a few years of using stacks with sheet metal coverings. It held about 5 cords. We had a splitting area next to it.

In 1994 we had access to a lot of free lumber and beams and we decided to build a real woodshed/garden shed/trash shed. It holds about 9 cords.

The experience of not having to cut down trees led us to the company we use now. We get truckloads of log length hardwoods every other year. To do this we had to move the wood area to the other side of the yard, in an unused part of the front pasture.

The wood we found for ourselves would be whatever was offered, but only hardwoods. The truckloads are a much nicer mix of oak, white and gray birch, cherry, and maple. There’s the occasional hickory and ash also.

My husband split it by hand for many years. He would always use a tape measure and sidewalk chalk to mark the 16” lengths he preferred for the stoves. He would split big chunks, and smaller stuff for starting fires.

In 1999 we both got really sick with chronic illnesses. He developed arthritis from his illness and we got him a woodsplitter.

With the Vermont Castings stoves we could go through up to 8 cords a year. We’d only burn the cellar stove if the temps were near or below 0F.

My husband builds custom deepsea fishing rods and does restorations on antique rods. In 2015 he expanded his shop into the whole cellar of the small side of the house. Because he was working down there most days, he would keep the stove going, something we had not done since 1991. The Pacific Energy stoves use about 5 cords, even with the steady burning of the cellar stove. It’s the upstairs stove that doesn’t get burned as often now.

Wood Equipment

I built a woodbox that held newspapers, kindling, small wood, and logs.

We also keep iron pots on the stoves with water in them to humidify the air. Wood heat is notoriously drying. Just ask our antique wood furniture…

There will be a new woodbox next to the masonry heater in the living room. My husband says I’m not building it…

We also have an assortment of bellows and fireplace gloves for each stove. My husband made ash scrapers for the Pacific Energy stoves from pieces of conduit and square electrical plates. These pull the deep ashes forward pretty nicely. We use old style ash shuttles for ashes, usually found at tag sales. We have a couple different log carriers for bringing wood in.

We also keep a good size stash of bags of newspapers for starting fires. We seem to do construction around here often enough to generate bags of kindling wood for starting fires. There was a time when we ran out and we scavenged tobacco lathes for kindling. We still have a stash of those in the barn.

Outside there’s a peavey for moving logs, 2 sizes of pickeroons for moving chunks, splitting mauls and axes, and splitting wedges. Someday soon there will be a huge sawbuck for cutting up the logs.

So this is our experience of 40 years of burning wood for heat.