This will likely be the last of my posts in this short "Touching History" series that I have done. If you dig back through my past posts, you will probably find another one kind of similar to this one from 2020. We honestly didn't intend to revisit the Quincy Mining Company, but through an unfortunate(?) series of events, we found ourselves back here.

Since my wife and I had already visited the Quincy Mine on a past visit, we were hoping to take our friends to one of the other countless mine tours that are in the Keweenaw Peninsula of Michigan. It's not that the Quincy Tour is bad, we were just hoping for something different. As luck would have it, the one we had our eye on was fully booked for the whole week we were visiting, so we ended up heading back to Quincy.

There are a few things about Quincy Mine that make it stand out from the rest, and because of that, it is never a bad idea to take the tour if you are in the area. First, it had the largest steam hoist ever built at the time in operation. Second, it was one of the longest mines ever dug clocking in at almost two miles deep. Finally, it was the second largest mining company in the area at the time topped only by Calumet.

You will have to forgive me, but I am going to pull from Wikipedia for some of the facts and figures in this post as I don't quite remember everything our tour guide told us!

The two pictures above are the shaft house for the number 2 shaft. The building at the beginning is where the hoist was kept. It may not look like much now, but remember, at the time, it was the largest steam hoist ever built and the longest mine shaft ever dug.

This picture gives you a better idea of how it would have worked back in the day. There would have been two sets of two cables coming out of the hoist house and running across that trellis into the mine. It was a dual hoist so while it was pulling up close to 10 tons of ore at a time, it was also lowering workers into the shafts. All at a blazing speed of 36 miles per hour.

In case I forgot to mention it, the kind of ore we are talking about is copper. There is a reason this whole area is called "copper country". Basically, many many many years ago, there were volcanoes in this area. You might recall me mentioning that in my past posts.

So those volcanoes kept spewing out lava and magma. Over time, those layers built on top of each other and became so heavy that they sunk back into the ground and created a large "carter" or depression reaching all the way from the Keweenaw Peninsula to Isle Royale and was eventually filled in by Lake Superior.

Over time the water that was trapped in the porous layers of volcanic rock would move down towards the Earth's core. At which point it would heat up and turn to steam carrying minerals like copper back into the porous layers of rock and when it got cool enough to turn back into water it would deposit the ores there.

Due to the slope of the layers, this meant that mines were dug at roughly a 54 degree angle and that is the slope the miners would work at. I have some pictures coming up that will show you this. When you go into the mines, the layers of rock are visible and you can see the 54 degree slope at which they run.

They have a small museum in the hoist house and that is where you start your tour should you choose to visit the mine. Long before people started mining gold and silver in the western part of the United States, miner were digging for copper in the northern part of Michigan. The copper rush in 1843 is considered the first great mining boom in the US.

Along with that, the exposed volcanic rock in the Keweenaw Peninsula is considered some of the oldest exposed rock in the world which is really the reason I called this series "Touching History". When you are in the mines, you can actually touch the rock that dates back 1.1 billion years.

They have a model of what the mining complex would have looked like back in the day. I am going to share some of that with you.

I felt it was only right to include a close of this train model for @livinguktaiwan's train community.

Finally, the model of the hoist house and the mining shaft in the background there. As you can see, this was no small complex. Like I said, Quincy was probably the second largest mining company in the Keweenaw Peninsula back in the day. They were known by the nickname "old reliable" because it paid a dividend to investors every year from 1868 to 1920.

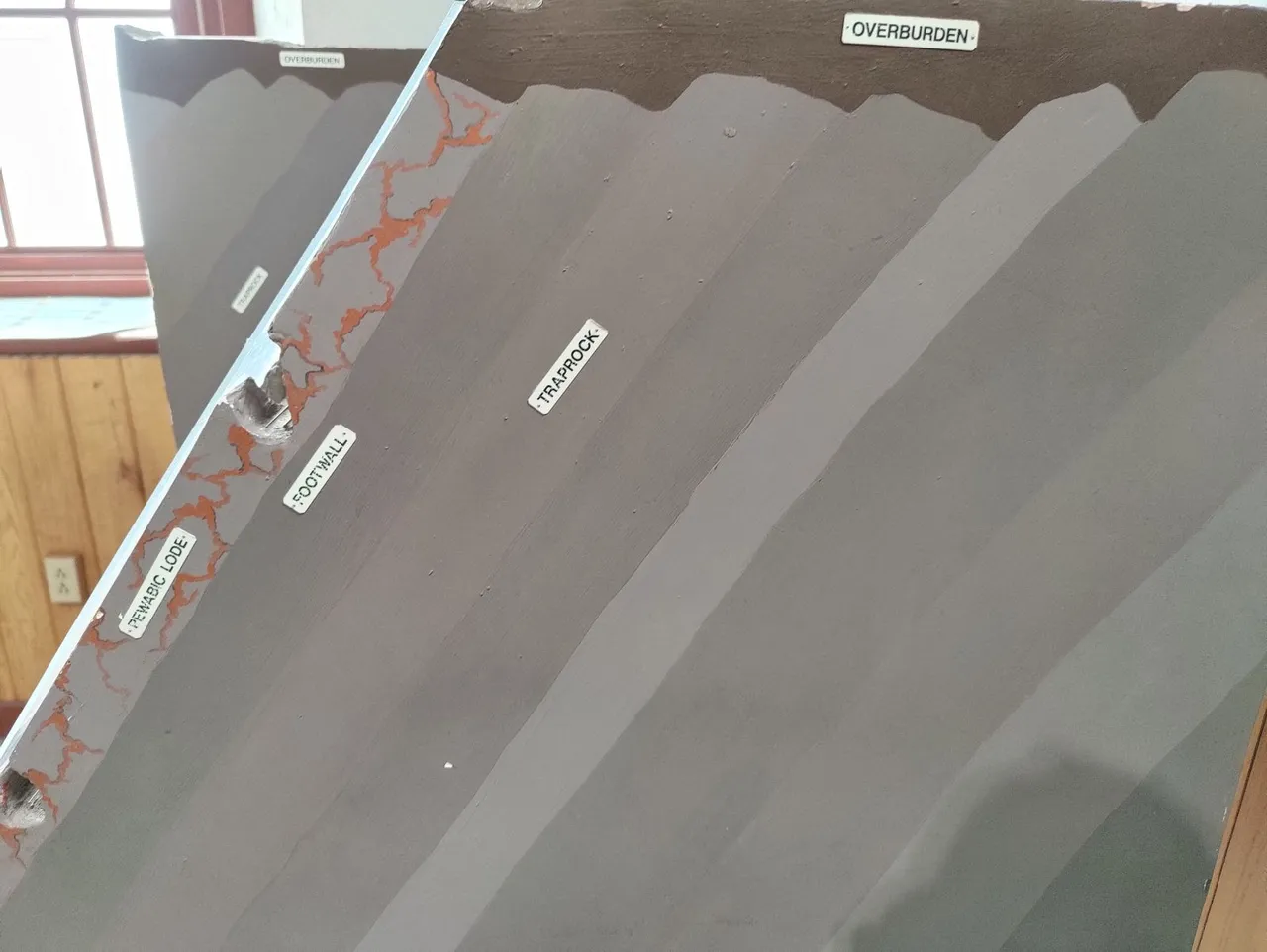

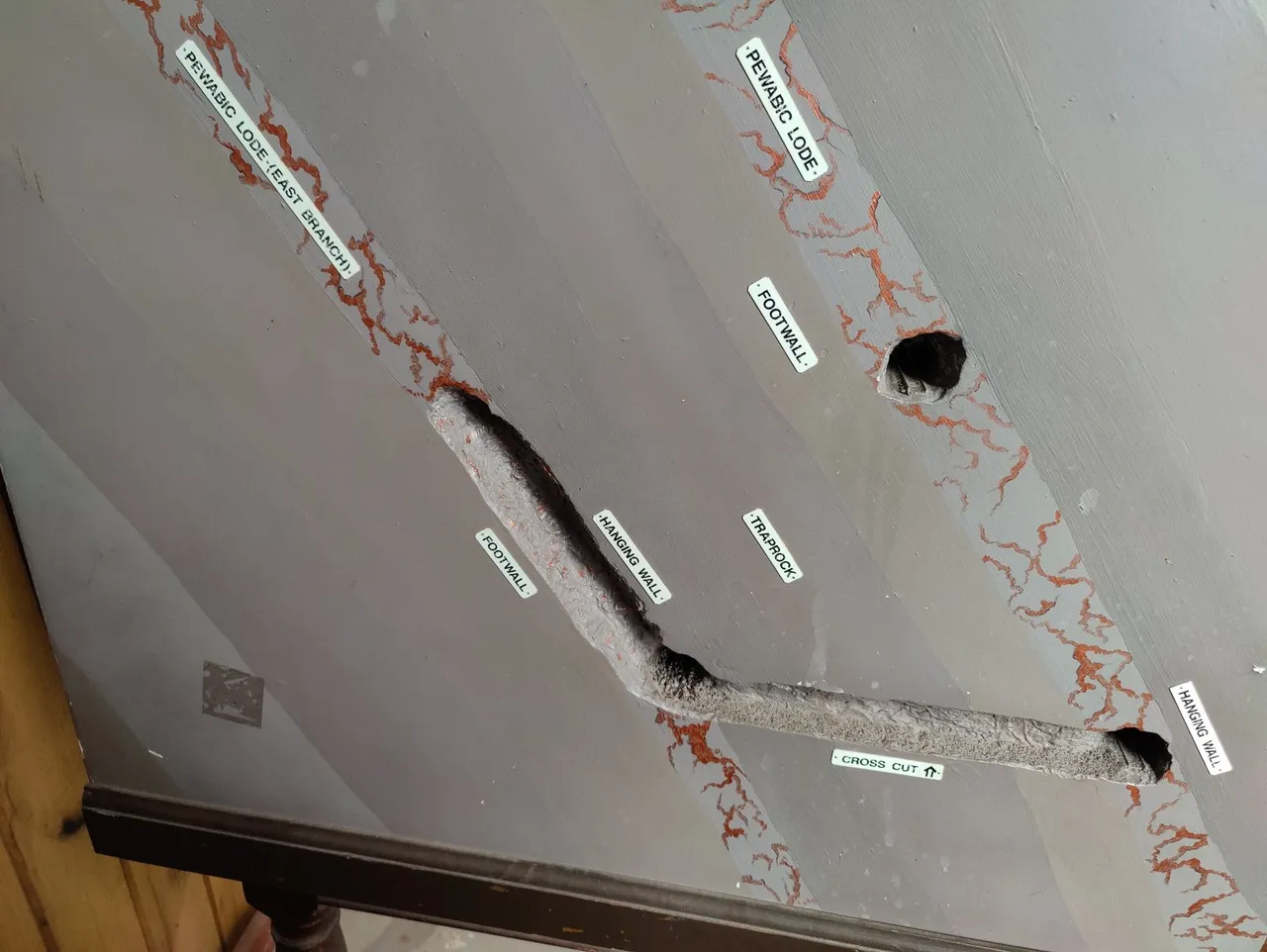

This is a model of what the mine might have looked like back in the day. It also gives you an idea of the slope that miners had to work at. Remember, this was quite some time ago, so they were using hand tools, ladders, and candles to do all of this.

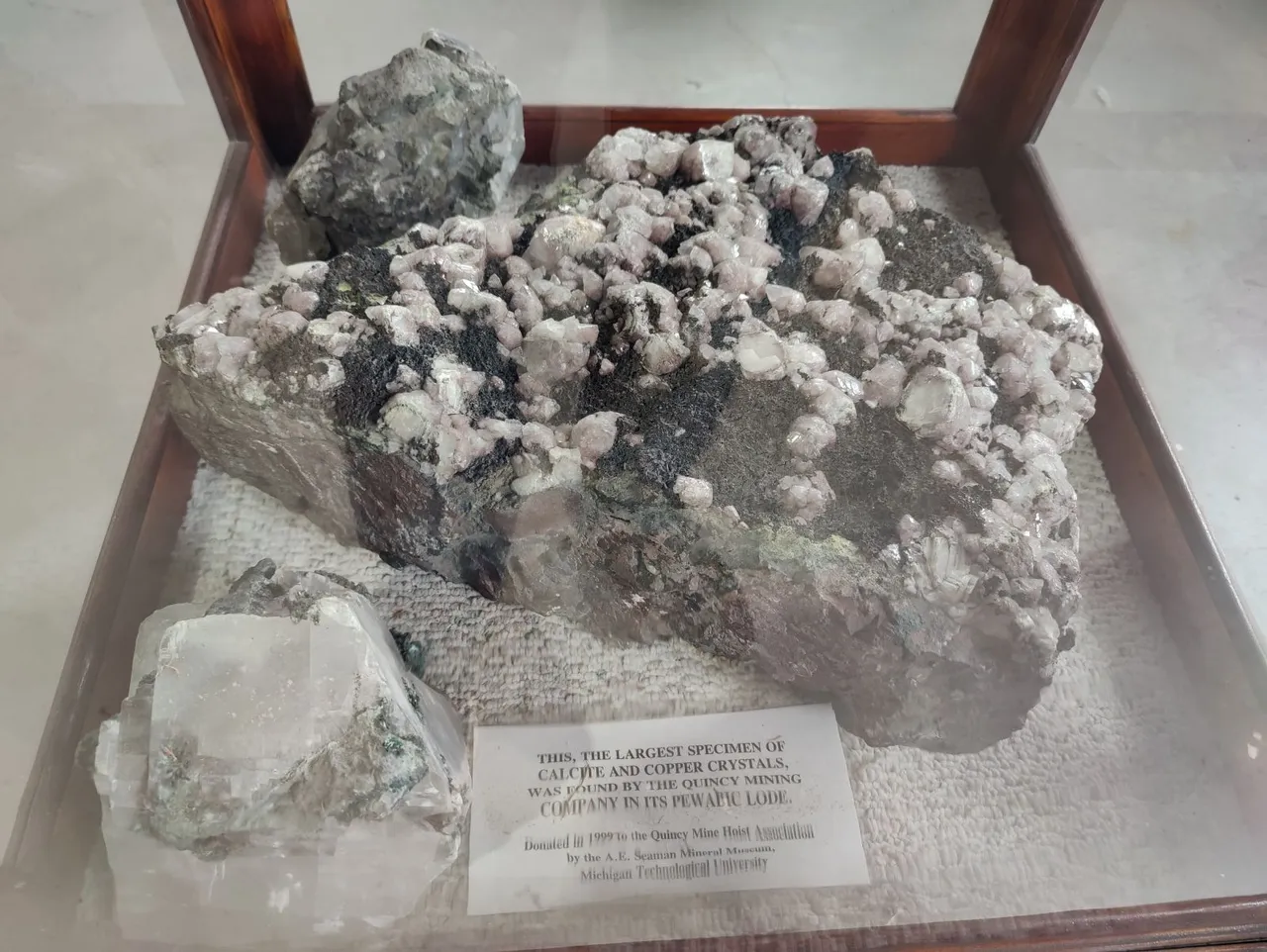

Due to the process that I mentioned above of water heating and cooling and carrying the minerals into the porous rock, the copper was spread pretty randomly throughout the rock. One specific band was called the Pewabic lode. It is interesting to note that of the raw stone that Quincy Mine pulled out of the ground, only about 2 to 3 percent was actually copper. It might seem small, but it was still enough for them to turn a profit. The larger mines further north in Calumet, MI were using a different process and pulling in about 4 to 5 percent copper.

This is a side view of that same model from above, and it gives you an idea of what the layers of rock would have looked like and where that Pewabic lode sat in relation to them.

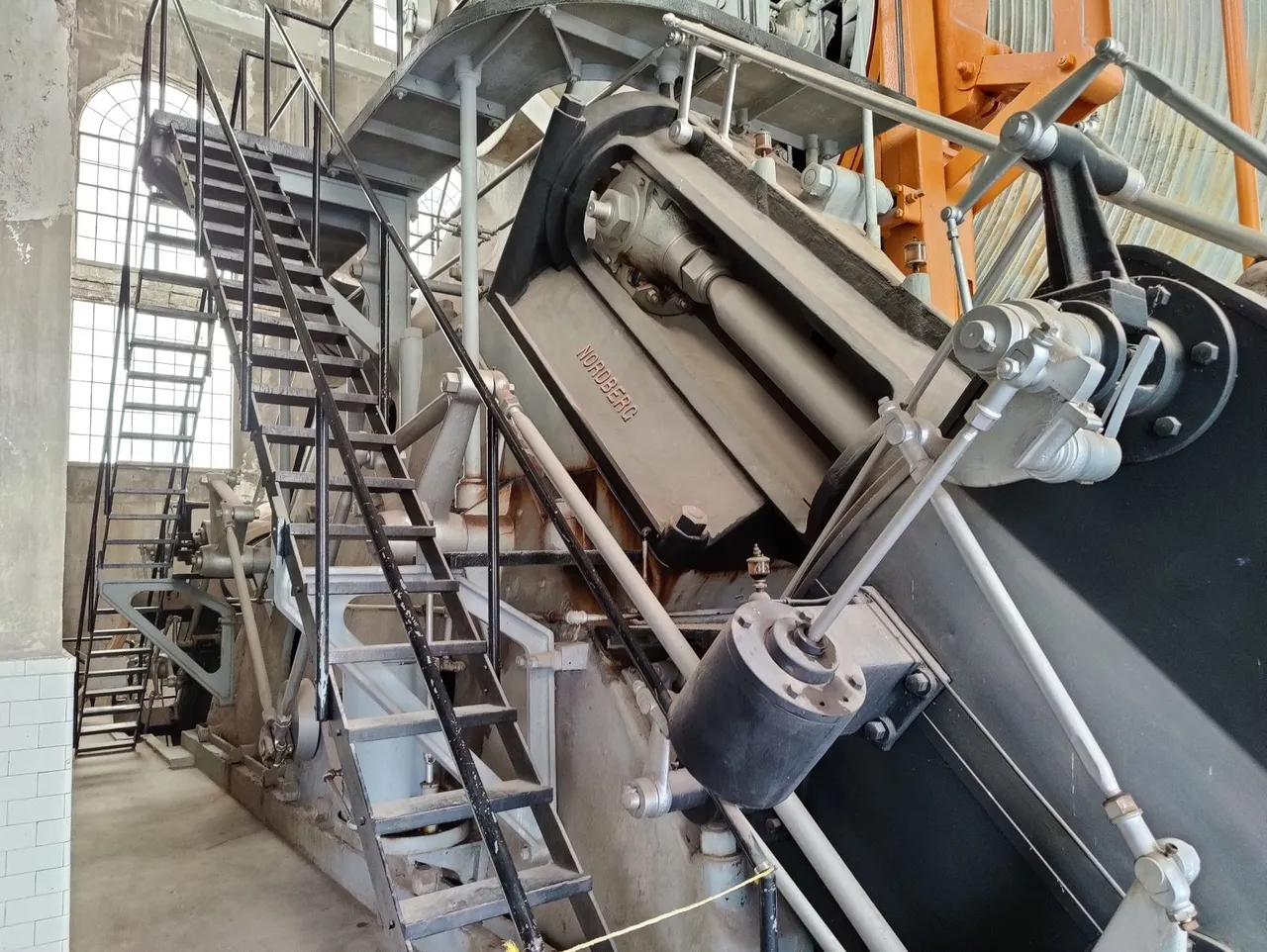

The owners of the company wanted the new hoist that they were having built to be a showpiece, so they went all out in the design of both the hoist and the building.

Built by the Nordberg company, the steam hoist was housed in a concrete building built in the Georgian architecture style. The hoist sat on the largest concrete slab ever poured at the time and the hoist house had a brick veneer and Italian wall tiles on the inside. The total cost for the hoist was $370,000 and they only used it for 11 years before ceasing operation in 1929.

After a lengthy but informational tour through the hoist house, we got on the cog tram to take us to one of the mine entrances.

The entrance to the mine tour is actually what is called and "adit". An adit is a horizontal shaft that leads you into a mine versus a vertical or sloped shaft. This particular adit takes you into the seventh level of the number 2 shaft. Although the number 2 shaft is 92 levels deep, everything below the seventh level has been flooded from ground water seeping in over the decades. Unless you have SCUBA gear, we went as deep as you can into the mine these days.

It's always a brisk 43 degrees in the mine, so if you go in the Winter you might actually feel it is warm, but if you go on a hot summer day like we did, you will find it quite refreshing.

This is an area near where the adit meets the mine shaft and you can see the slope at which the workers had to do their job. Apparently, it was nothing for the Cornish miners that came across the ocean, but for the inexperienced, I can imagine it was quite harrowing!

The tour really is quite amazing and if you had to pick one single mine to visit in the Keweenaw Peninsula, you definitely wouldn't go wrong choosing Quincy.

Sports Talk Social - @bozz.sports