Introduction

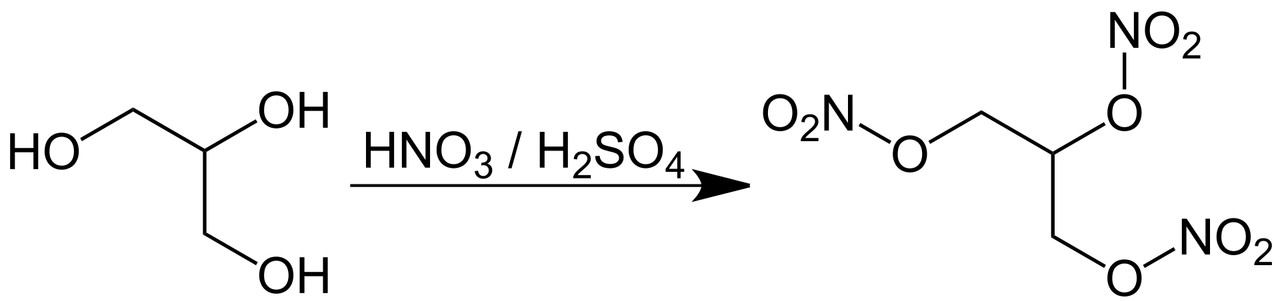

Nitroglycerine (NG) is a very interesting substance. It can be used in the medical industry to treat certain heart conditions, but far more famously is its use as a high explosive. Interestingly enough, although has a real nasty reputation for being super sensitive it is actually a relatively difficult high explosive to initiate requiring the use of a primary explosive (like fulminating mercury). When exposed to fire it will usually just burn (or rather deflagrates if you want to use the technical term. Deflagration is when the combustion rate is subsonic, detonation is when the combustion is supersonic). This isn't to say that nitroglycerine is safe, especially when impurities are present. Certain impurities that can either be produced or occur from degradation of the NG are also high explosives but they are far more shock and heat sensitive which can result in the impurities acting as a primary explosive.

Safety

When doing this synthesis: Do this outdoors in the shade but where the fumes can freely vent off. Secondly make sure that the temperature of the reaction stays between 22oC and 25oC. I know a lot of sources say its safe to go up to 30oC but really if it hits 30oC you should be drowning the reaction (dumping the reactants into ice water, around 10x the volume of the reactants). Better yet, drown the reaction before you get to 30oC if you cannot cool it, your hands and life are worth more than the cost of the reactants here.

Required Ingredients

Fuming Nitric Acid, preferably white fuming.

Glycerine (Glycerol), can be bought quite easily from supermarkets and drug stores. If not easily available my next post will be about salting out glycerine from the saponifacation of triglycerides (though the steps are the same for both esterfacation and transesterfacation of triglycerides).

Sodium Bicarbonate (baking soda)

Sodium Chloride (table salt)

Ice and water to make ice baths along with containers to contain the ice bath (any plastic container should really do).

Glassware, borosilicate glass is personally recommended though if you plan on doing this synthesis on a large scale it would be better to produce a proper reaction vessel.

Synthesis

Step 0: plan out how much nitroglycerine you plan to produce, if you want 5ml of it then from step 2 and 3 you will want 5ml of glycerine, 20ml of nitric acid, and 30ml of sulphuric acid. The ratio is 1:4:6 (glycerine, nitric, sulphuric).

Step 1: Dilute your nitric acid down to approximately 62% mass concentration. Ignore this step if you are buying nitric acid. The density of the nitric acid should be around 1.37-1.38 g/ml.

Step 2: Mix your nitric acid into your sulphuric acid in a 4:6 ratio respectively (yes this reduces to 2:3 but when adding the glycerine in the next step the ratio will make more sense). Mix in your reaction vessel and chill to below 20oC (I find 18oC to be where I get the initial mixture to).

Step 4: Once the reaction has gone to completion and all of the glycerine is added you need to neutralize the acid. To do this you mix together a bicarbonate solution around 10x the volume of the reactants. Exact concentration I don't believe is to particular, I go with around the stoichiometric amount of bicarbonate but a little excess will not hurt.

Step 5: Once the bicarbonate solution is added, mix the reactants into the bicarbonate solution and let sit, lightly stirring occasionally, for around 24 hours.

step 6: Separate the oily nitroglycerine (which will be milky and possibly yellow if it contains a lot of contaminants) out of the bicarbonate solution. The milkiness or fogginess of the NG is caused by water being absorbed by the NG and thus we just need to dry the water.

Step 7: Prepare a saturated sodium chloride solution and add the NG to the sodium chloride solution. Once the NG is clear and no longer milky, separate again. The saturated sodium chloride solution will pull the water from the NG solution, effectively drying it.

This should give you a clear solution of nitroglycerine. If it is yellow then you have nitrogen oxide contamination which will impact the effectiveness but as long as you are just using this for little hobby tests it shouldn't be too big of a deal.

Separation of Nitroglycerine from Solution

NG is not exactly soluble in water and will instead separate into an oily layer (depending on how much). This means separation can be done via a separation funnel.

NG also freezes at 14oC allowing for filtering to be used. However be careful to prechill the filter to below 14oC as to not have the NG melt on contact.

Storage

If you plan to store NG then do so below 5oC however long term storage does risk instability as it degrades (though it will degrade far slower when stored properly). I would not recommend storing a lot. When removing NG from storage, make sure to heat it slowly as large temperature changes can cause it to degrade and even risk degradation products detonating. The other risk of rapid shifts in temperature is spontaneous deflagration (combustion).

Detonation

As I said, NG usually requires a primary explosive to initiate a detonation. However, with small amounts of NG you can safely induce detonation by hitting it with a hammer.

Function of Sulphuric Acid

This is a question that, although it doesn't come up, does need to be answered as there is a lot of misinformation provided on forums for the role of sulphuric acid in this reaction.

The sulphuric acid is used as a catalyst and removing the sulphuric acid will just make the reaction go slower.

The sulphuric acid here is used to do two things, first it makes protonated nitric acid species which is more likely to be attacked by the oxygen atoms in the glycerine which results in water being produced and the hydroxyl groups changing to nitrate groups on the glycerine molecule. Secondly the sulphuric acid will pull the water produced out of the reaction which can prevent oxidation of the nitroglycerine, which would result in nitrogen oxides being produced along with other contaminants, some of which are more sensitive and thus dangerous. So while the sulphuric acid does speed up the reaction, technically, because it gets deprotonated doing so it isn't a catalyst and its role that it plays is far more involved.

History

Nitroglycerine was first synthesized in 1847 by an Italian chemist named Ascanio Sobrero. However, at this time it was relatively difficult to use as a controlled explosive and there came a hunt to find a way to use it as such. In the years following another chemist named Alfred Nobel took to experimenting with nitroglycerine looking at ways to stabilize it for use as a controlled explosive. His most famous method of doing so involved mixing the nitroglycerine with diatomaceous earth and then wrapping it with greased paper to make it waterproof, this became known as dynamite. It is also used in smokeless propellants like cordite and ballistite.

Medical Uses

Legal Notice

This article is provided as is with open source information. It is meant as an educational publication. I take no responsibility for what you decide to do with the information present here. Furthermore, synthesis of nitroglycerine may be a criminal offense where you live without proper licensing. Unless you are a trained professional with legal authorization, you should not be attempting to make nitroglycerine. All of the information provided here is freely available online from a number of sources.

Sources

Material Compatibility

Nitric Acid Density

Video of detonation

History of Dynamite

Chemical structure, public domain

Forum

Explosives from nitric acid and sugarsNitric acid on some vegetable organic molecules

Nitroglycerine Medication (yes webmd is not a very reliable source for diagnostics but basic drug overviews it usually is okay)

Nitroglycerine Medication Image

Explosive Sign Image