If you know anything about me you you'll know I'm a shooter; Long-range and handgun primarily. I compete around the country at practical long-range shooting events, cull professionally and do some other things also.

When I say long-range I mean 1600 meters, a mile and more. It's something I've spent a lot of time mastering getting very good at long-range shooting and I hone my skills weekly.

In pursuit of repeatability and accuracy I make my own ammunition and have done a few posts here in The Pew: Guns & More if you're keen to scroll. Today I wanted to talk about another element as I made some ammunition over the weekend and, why not right?

6.5mm creedmoor rounds - The black and red sharpie marks are so, after firing, my brass can be easily identified from others and I get it back to re-use for reloading.

Long-range shooting is not an easy thing; Many elements have to come together to send rounds accurately to their point of aim:

Rifle system set-up, the zero, scope mounting and levelling process, weather factors like temperature, wind, altitude, humidity. Slope-angle the shot is being taken at, the point of the compass one is shooting, azimuth. Aerodynamics, the turning of the Earth, Coriolis...The shooter and his or her skills, the ammunition, target-movement and speed...If you think it's just pointing and shooting at the cross-hairs on the reticle then you'd be wrong; It goes far deeper. It is science....And the movies get it wrong.

I work to eliminate or mitigate possible causes for lack of accuracy in my shooting. This means that I train myself:

Trigger-pull, breathing, wind-calling, target acquisition, the speed at which I obtain field firing solutions, get the rifle-system ready to operate...I work at it all because not knowing those things intimately when not under duress will mean those problems will compound when something is on the line.

Weighing and measuring

I don't want to make this a super-long post but basically, I weigh and measure my ammunition.

Ammunition has an overall length tolerance, the OAL, of the completed round and this is tuned to the rifle-system I'll use it in. That process, of load development, is long-winded but it is critical for mission-success when operating.

I batch my empty cases by weight, discarding those that are too light and rotating the others through as required. I measure them for correct case-length tolerance and then when loading to make sure the projectile is seated at the exact depth required to deliver the OAL I need...Then I measure it. You can see how I do this below.

Some of the tools

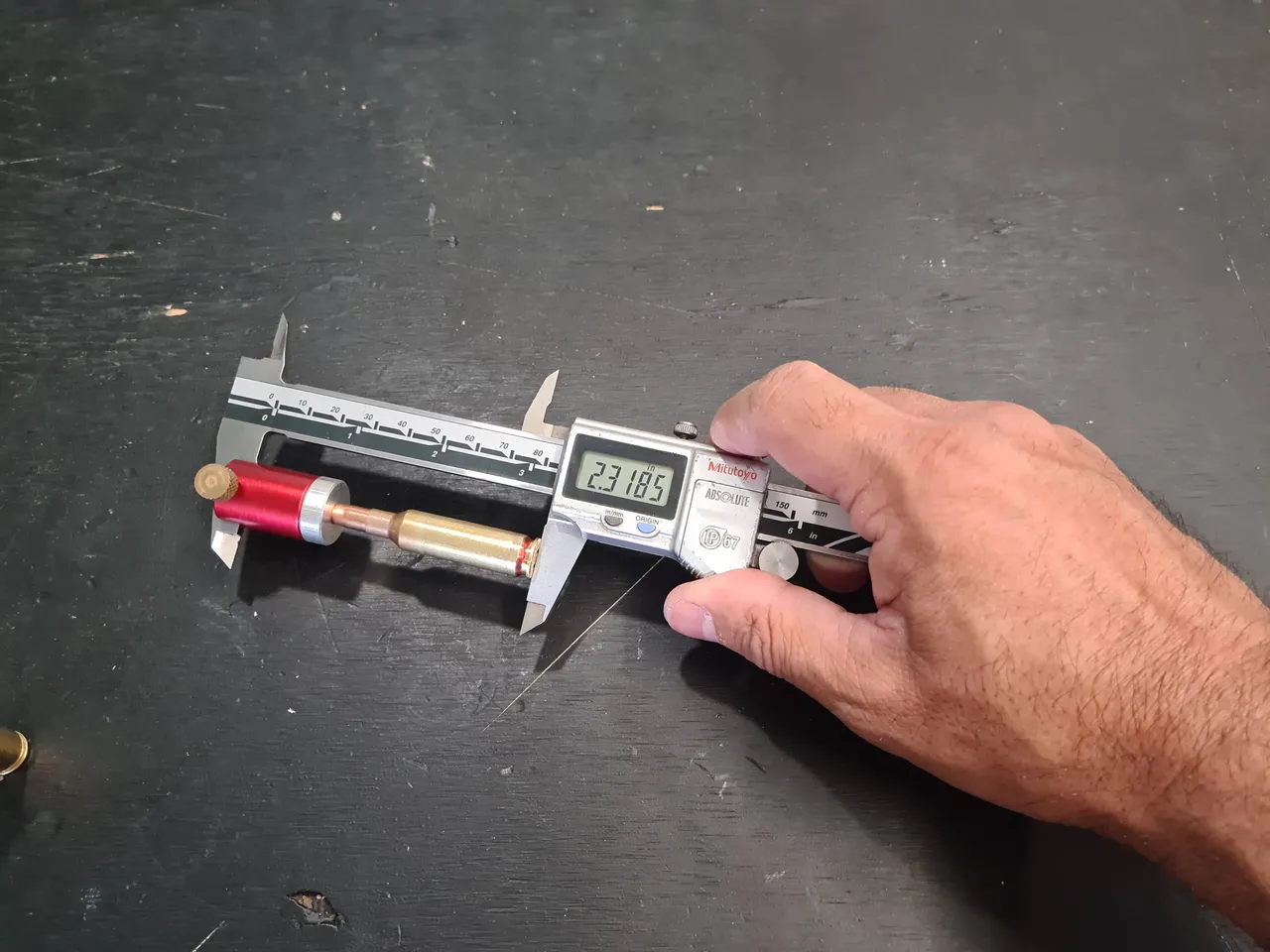

Mitutoyo vernier caliper measuring an empty case. There's a minimum and maximum tolerance - Too long and I trim it, too short and I toss it.

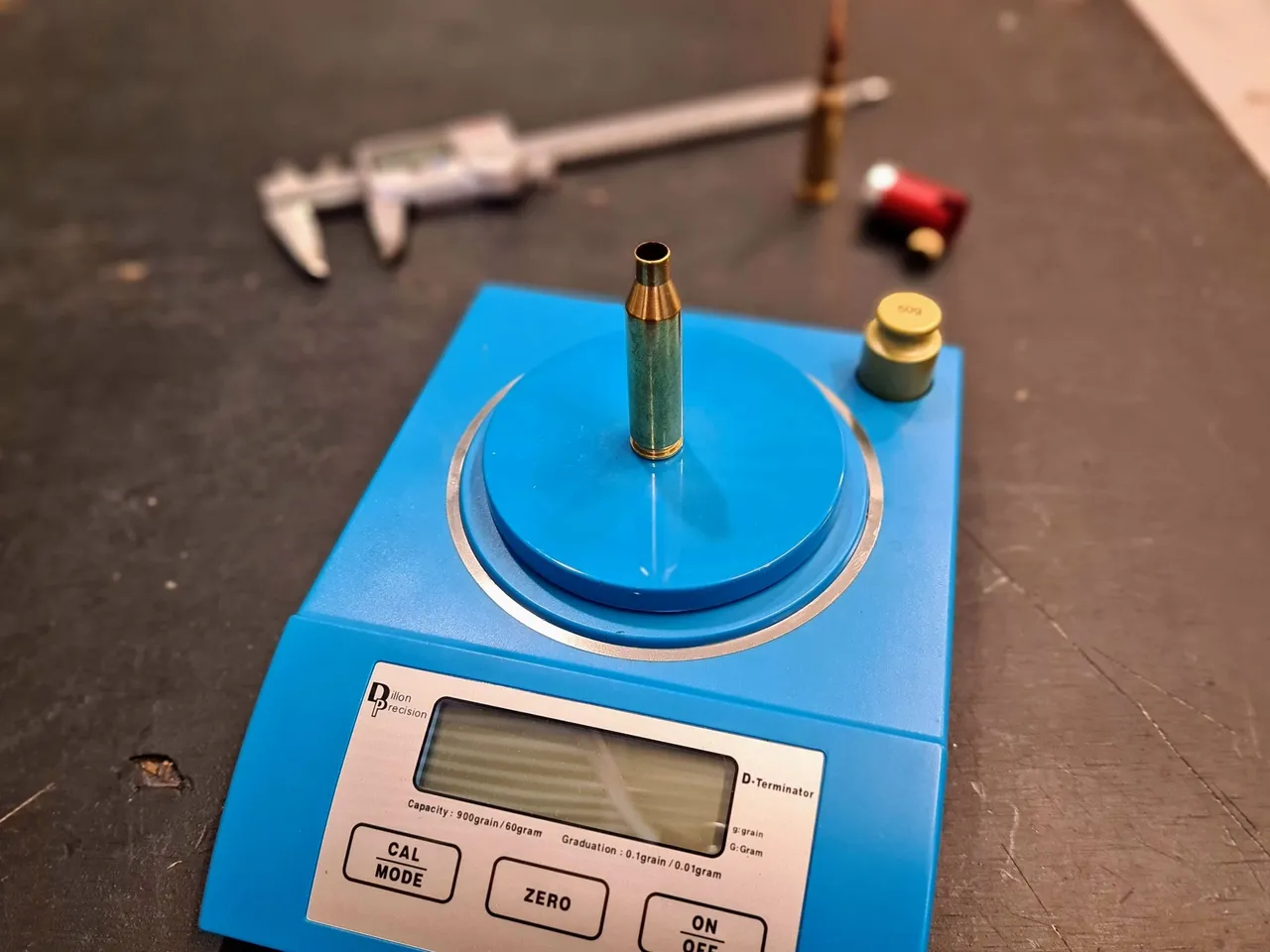

This very sensitive electronic scale is used for batching brass. I weigh each one and separate them into weight-batches. Too light and they become training rounds then are discarded. I also weigh the completed, reloaded, rounds to ensure they are full of gunpowder. Check, recheck, then check again - That's what mitigates risk.

Once the round is reloaded I check them for overall length, that OAL thing I mentioned above, but it's not as straight-forward as applying the vernier calipers again. I'm looking for precision here, so I have to be very accurate...And do things differently.

The image below shows HOW NOT to measure overall length.

The very tip of the projectile, called the meplat, can often vary from tip to tip so measuring off it is not going to give consistent results. The meplat is what cuts the air in flight and different meplat's will affect how the projectile behaves in flight; It affects the ballistic coefficient of the projectile.

So, I use a different method of measuring the overall length of the completed round. It's called a comparator gauge. A simple, but effective little gadget.

Comparator gauge

There's one below - It's a small thing really, with a big job.

What it does is allow the bullet to slip inside the calibre-specific gauge right up to the ogive. This part of the bullet is perfectly symmetrical and allows for consistent measurement or each round.

The images below show how it works. The bullet simply slips into it until it hits the ogive which is where it stops. See top right and lower right below where I've shown where the ogive is both in and out of the gauge.

The comparator gauge attached to the vernier caliper and once re-zeroed is ready to use.

I measure every precision round I make; Yes it takes time, the entire process of reloading precision ammunition takes a lot of time really - But not doing it right at every stage will affect the final shot.

This next set shows the gauge attached to the caliper which simply screws on. You can also see a round being measured; See where the gauge has stopped on the ogive in the top image? Also, the lower right image shows the meplat on a projectile that I was talking about earlier.

Another gratuitous hand-shot showing me operating the vernier caliper to measure overall length of a completed round. The vernier caliper measures in millimetres and inches - I use inches.

Another close up of the tip of a round. In this one you can see the anomalies in the meplat quite clearly. The meplat is also where the projectile will typically "mushroom" out to cause more damage to the target.

Most military and law enforcement snipers and sharpshooters use factory-made match-grade ammunition due to the volume they require. I have a lot of experience with it and good, repeatable, results can be achieved although I found that the standard deviation in muzzle velocity was not acceptable for what I wanted and so I moved away from it; Having a standard deviation of over 10 feet per second was not going to work for me. It's also much more expensive to purchase than making one's own.

Making ammunition is a constant process for me; I can always be found doing one element of the process or the other but I actually enjoy it a lot. I find the repetitive action relaxing and with some tunes and snacks...I'm set for a day.

Many of my shooting mates do not go to the extent I do when it comes to ammunition; If I was making hunting rounds I'd not do it either to be honest. I don't do this process when making handgun ammunition either, volume is the key there. For long-range though I see it as essential, and enjoyable.

If you have any questions or comments feel free to drop them below, I'm happy to clarify anything. Thanks for reading.

Design and create your ideal life, don't live it by default - Tomorrow isn't promised so be humble and kind

Discord: galenkp#9209