Hello Everyone,

It's been almost a week since my last post so I wanted to make an update post to let all of you know what I am currently working on.

I'm working on a design for the Ender 3 V2 4.2.2 motherboard, and currently am about 50% done.

But this project has taken a bit of a backseat while I work on something cooler.

So let's talk about that first.

I'm building a indoor greenhouse/tent like enclosure for seedling plants.

I found this super cool building frame on Thingiverse and I see so much potential for projects, and even have some ideas forming for creation of some DIY kits with these specific building parts since I can scale them smaller or bigger to adapt to different applications.

Building Frame

by anthoney84 January 06, 2021

Building Frame byanthoney84is licensed under theCreative Commons - Attribution license.

Building Frame

by anthoney84 January 06, 2021

Building Frame byanthoney84is licensed under theCreative Commons - Attributionlicense.

It took quite a bit of searching on Thingiverse to find this, about 3 days of searching.

Apparently construction frames with all parts 3D printed are a little difficult to find, (or I am using inefficient keywords :D) but anthoney84 pulled through with this beautiful frame for the community.

I imagine designing something like this wouldn't be too difficult, and with a limited array of them available, I am considering designing some different styles of this (remixes) in the future.

For now I am just going to use this one :)

This is currently a work in progress for me, and will probably take at least another day to complete.

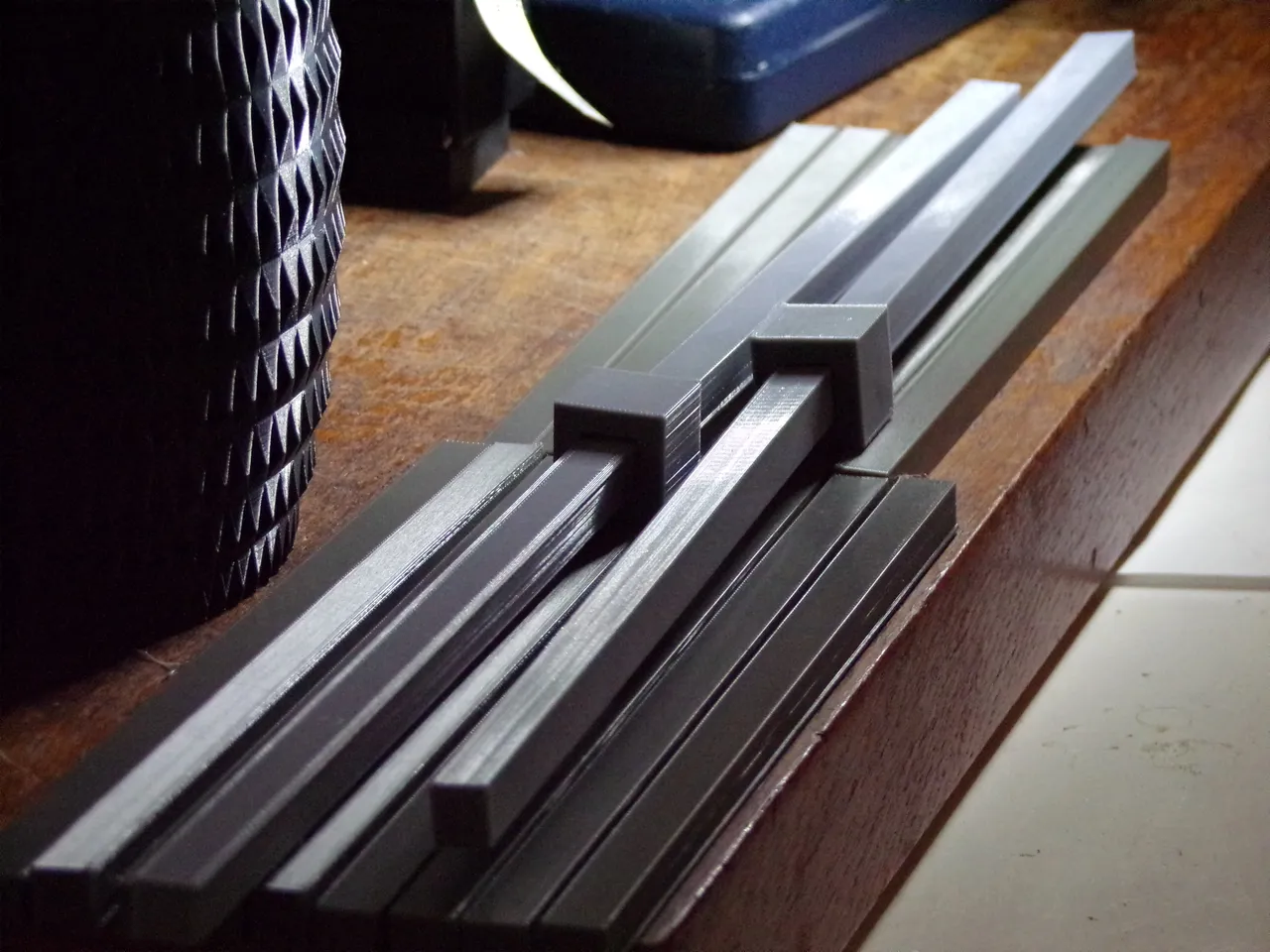

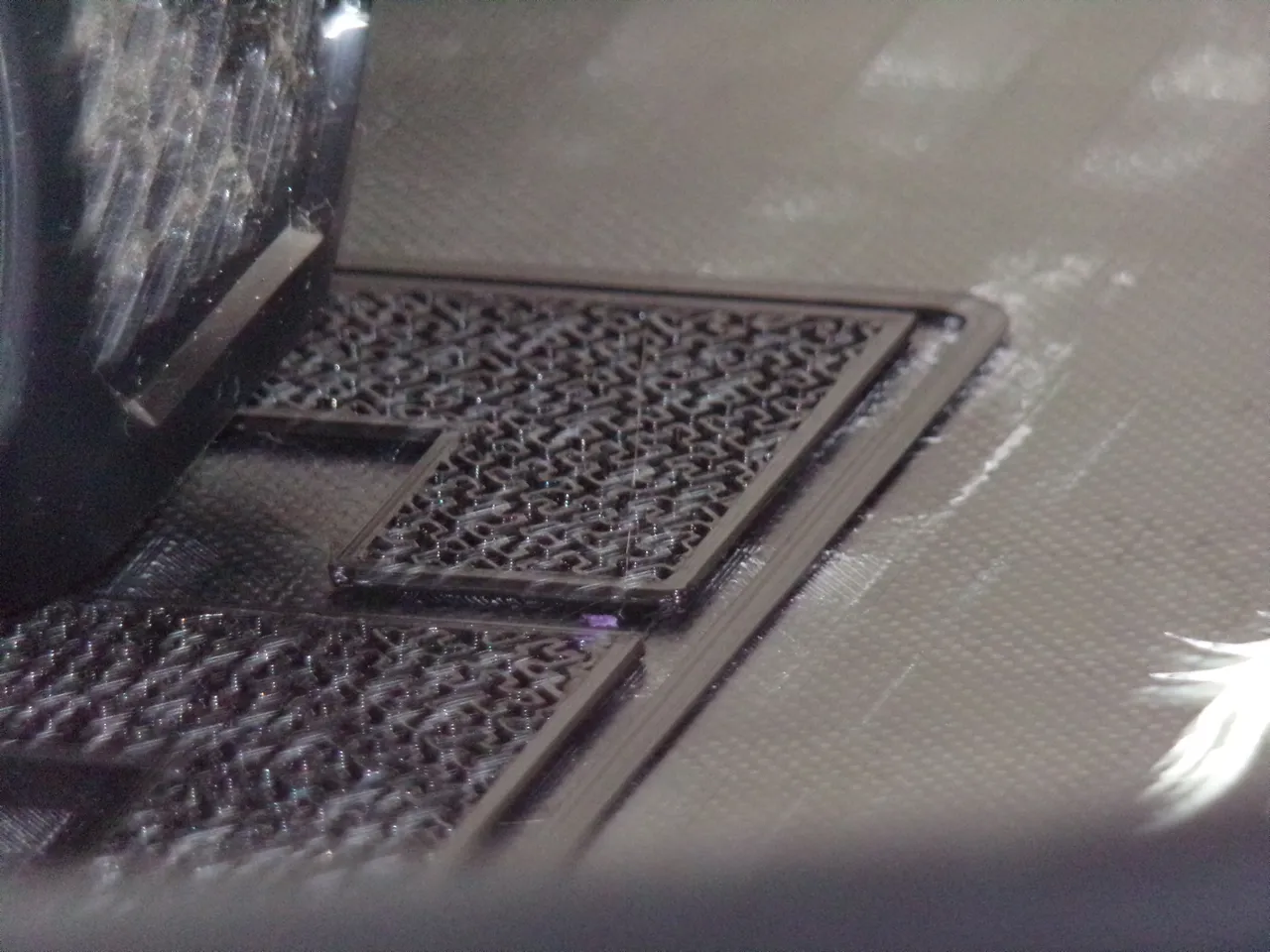

Printed at 0.28 mm layer height, the 200 mm "pipes" (which are laden with 30% hilbert curve infill) have been printing for about 18 hours total, utilizing TECBEARS PLA grey and black filament.

(The connected pieces on top were printed with Esun grey, last on a roll I had, hence the small color deviance.)

I may introduce more colors and different filaments into the structure because I'm starting to run low on filament and need to get some more.

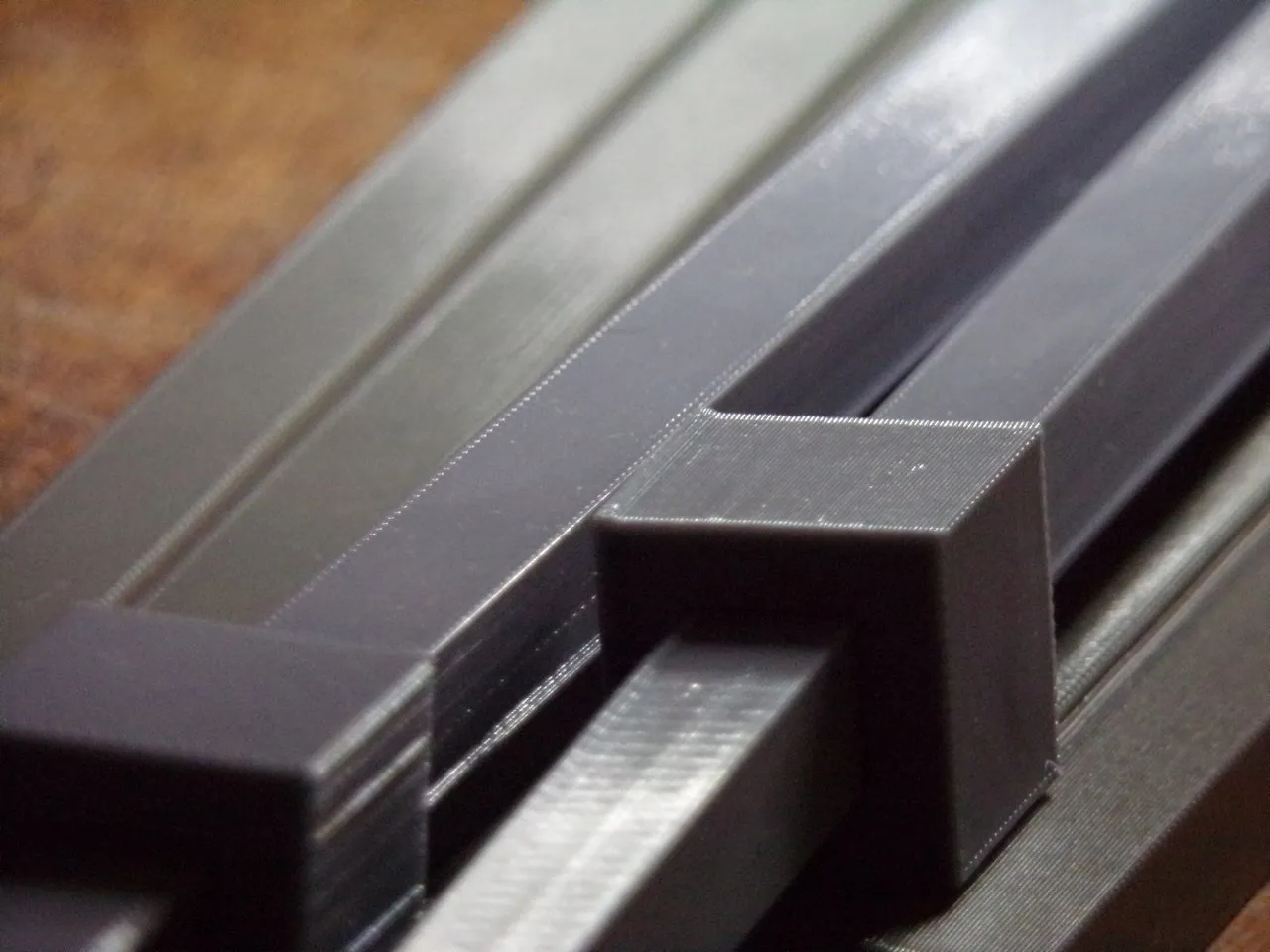

There is absolutely nothing to complain about with these printed parts. The connecting pieces fit tightly together with no need for glue, and the printer has been producing consistent nice prints. It's very exciting to see these beautiful parts printed off a machine that was previously producing failed prints.

The next post will likely be about this frame, in its expected glorious completion.

MOTHERBOARD DESIGN

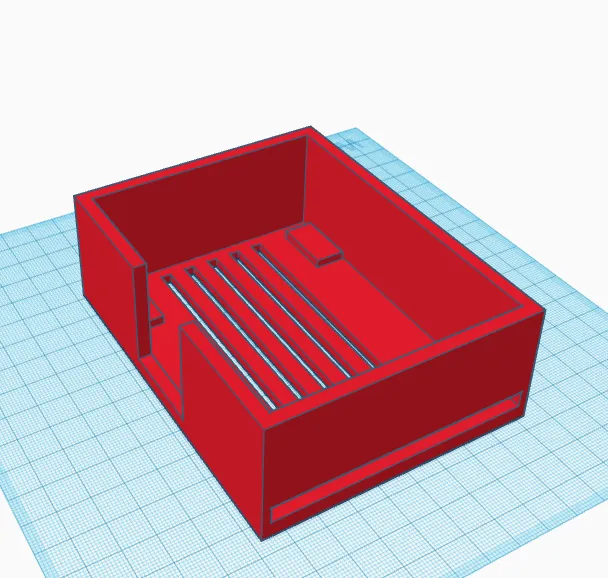

What the viewer will now see is a prototype (not the part that will be used.)

This is the bottom piece to the mobo case I have designed. This is a prototype and I have a very nice clear printed bottom piece, but I am going to save that reveal for the completed mobo case post ;)

There are obvious layer separations that have occured.

Reason:

Heat too low, speed to fast.

Printed @ 0.6 mm layer height with TECBEARS PLA, extruding filament faster, need for higher heat.

This will cause layer separation, and was the cause of this print coming out so horribly. I verified this to be the case later on. Darker filaments will oftentimes need higher heat, and utilizing temps for a previously used filament that may have required less, can cause this to happen.

Attention to these small details can be the difference with a big hunk of wasted filament, or a nice print.

Lesson learned!

Here is the model in Tinkercad:

It is pretty simple.

I wanted ventilation on the bottom, a slot for the interfacing, and some feet to raise the board so it's not sitting flush on the bottom.

I opted to not place screw holes in, because of my addiction to using hot glue,

and I even forgot to add feet so I could have an excuse to use more hot glue :D

Actually forgetting the feet was a mistake that I think was a good mistake.

Not having feet added means I do not have to worry about supports, (wasted filament)

and can simply print small feet to glue on. There won't be any structural worries, as it just needs to hold a small PCB board.

and although for some this might be a gripe, I'm the designer and feel it is perfectly fine, so this is how things are going down.

More updates coming soon!

Thank you for stopping by,

Have a great day! ~~@print3dpro