I opened my glassblowing shop in June of 2014. It was quite a process, and took about 3 months to come to fruition. The main task is getting a good ventilation system running before you turn any torches on, which is essential for health and safety. In this post I will show the process of building my shop, list the materials, and equipment required. I will then display where we are today. If you are new to my blogging or glass in general please feel free to check out my Intro, and the first Giveaway which goes in to great detail about Borosilicate. The @cryptocameo glass blog is full of knowledge and surprises!

In my mind the shop is about 90% complete. The cherry on top for me, was the acquisition of the Oxygen Concentrator, which we use to produce our own Oxygen on site. It saves us quite a bit of money, and it is a lot better for the environment to boot. I put all that I have in to this shop, and though sometimes we neared rock bottom, it was all worth it. When hard work meets opportunity, incredible things can happen.

When I began blowing glass, I worked in a very abusive environment. The first shop that I worked glass in belonged to another fellow who sadly fell off to drug addiction. He always had a problem with it and tried to hide it with most people. It was very dirty, he owed a lot of people money, and it was even a little bit dangerous to be around there when it all started falling down. Sadly he ended up losing his shop, significant others, respect of peers in the industry, and nearly life itself. He was very well known, and was even on a team that won a nationally recognized glass competition called CHAMPS in 2009. He would steal from others, lie, and scheme. I'm sure many of you have met folks like this. Luckily I was already working along side a couple glassblowers there who are wonderful people, and we had a plan just in case.

My two friends and I, we trained together at the first shop I just mentioned for a couple years. We left this abusive environment very quickly to form our own collective of glass when we began to see the management of the first shop fall to shambles. I am so thankful for my friends and the could not have made the transition without them. They work VERY hard and deserve recognition. I can only hope they come migrate to Steemit as I would really like everyone to see their work. I have encouraged them both to embrace Steemit and the advantages of blockchain technology in general, and I really hope that they do. If they begin to make posts, I will try to feature all of them in my upcoming blogs.

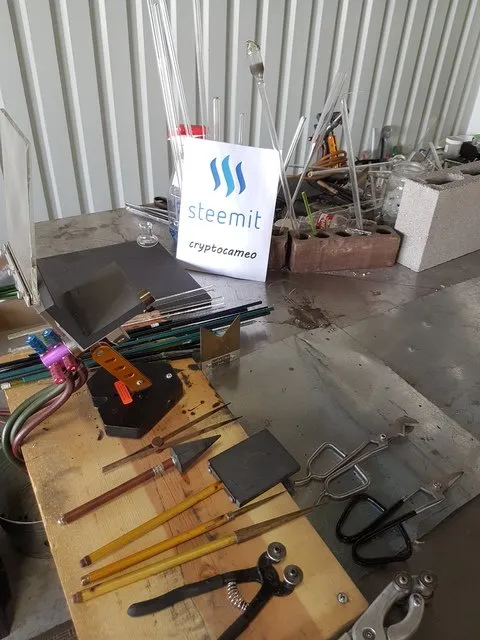

Take note, when you are attempting to try Borosilicate glass work, some of this equipment is mandatory for your health and safety. Also, please consider that if you are wanting to build a smaller setup, you can downsize a lot of this equipment. This is a full size glass production shop and would be overkill for any home setup. Keep in mind that what I have listed below is just my equipment, and not the graphite/metal tools I use to shape hot glass, which will come in a later post. Perhaps my peers shall post their glass, tools, and other equipment soon too. Feel free to ask about anything you see and I will try to answer.

Let's journey through the process together.

MATERIALS AND EQUIPMENT:

Sledgehammer

Clawhammer

Nails

Screws

Stainless Steel Shop Tables

Electric Drill and Drill Bits

26in Ventilation Ducting and Flexible Mylar Ducting

6ft by 3.5ft Stainless Steel Venthood with Chains

Ducting Suspension Straps

Scissor Lift and Ladders

3400CFM Fan-Tech Inline Fan (REQUIRED FOR YOUR SAFETY)

GTT Triple Mix Torches - Phantom, Delta Elite

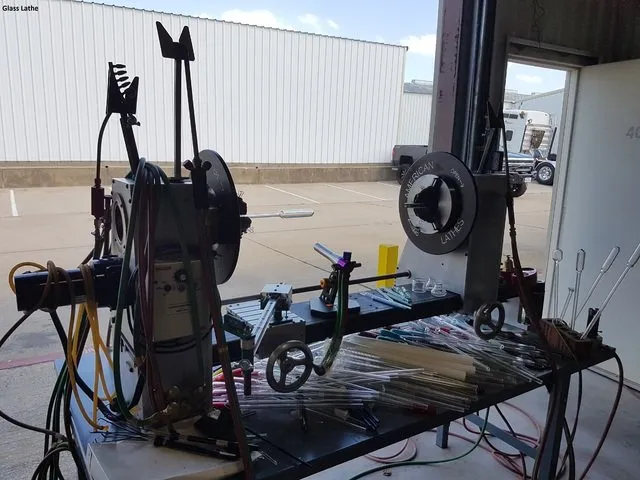

American Lathes INC. 5100 Lathe

The Blast Shield INC. Torch Stands

Gemini Revolution XT Saw

Portable Ban Saw

Sand Blaster Cabinet

Shop Vac

Air Compressor

HiVolume Oxygen INC. Electric Oxygen Concentrator

T-Grade Welding Hose (Propane + Oxygen Mix)

Skutt Scarab Flameworking Kiln

Griffin Glass Tools - Rock It Foot Pedal

Kevlar Gloves and Padding (REQUIRED FOR HOT EQUIPMENT)

BUILDING PROCESS:

FINISHED:

Thanks for taking the time to check my shop out. Lots of glass to come, especially from the lathe!

Until next time Steemit. For now, I will leave you with another teaser of what's to come.